1

2

1

A

B

★.Optional gauge size:3.2、4、4.8、8、9.5、12.7、

16、19、25.4mm

2. Main specifications

Model

Specifications

Medium and heavy duty

1800spm

9mm

8mm by hand, 13mm by knee

36mm

Large vertical hook with auto-lubrication

DP×17 Nm125-180

6.4mm (standard)

Auto lubrication (partial of manually oiling)

Servo motor 550W

The models adopt double (single) needle and two (single)

vertical hooks with auto lubrication for thread looping,

sliding lever for thread take up to form two lines of

lockstitch seam. The upper shaft and lower shaft are

supported by ball bearing and driven by teeth-type

synchronic belt; plunge oil pump lubrication system.

They adopt the compound feed mechanism of feed dog,

needle bar and presser foot, even if for long stitch length

and long material. This series can deal with them freely.

This series adopts numerical computerized control

sy st em , wh ic h is des ig ne d wi th a u t o - t ri mm in g,

a u t o - s e t t i n g s t i t i c h l e n g t h , a u t o - b a c k t a c k i n g ,

auto-presser foot lifter, etc. It is also designed with the

electrical servo motor.

This series is widely used in the factories of suitcase,

tent, cushion, leather, goods, apparel, mat, etc.

.

.

1. Brief Introduction

Application

Max.sewing speed

Max.stitch length

Presser foot lift volume

Needle bar stroke

Rotating hook

Needle

Needle gauge

Lubrication

Motor

3.1 Installation

3.1.1 Location of the machine

To ensure a smooth running, the machine should be located

on a rigid and flat floor. The insert of rubber mat between

machine stand and floor is recommended for further reducing

the running noise and vibration.

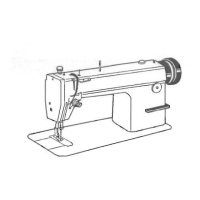

3.1.2 Installing the oil reservoir (Fig.1)

Put the oil reservoir into the table cutout, and place the four

cushions on the four corners of the cutout, then set the

cushions and oil reservoir in the table.

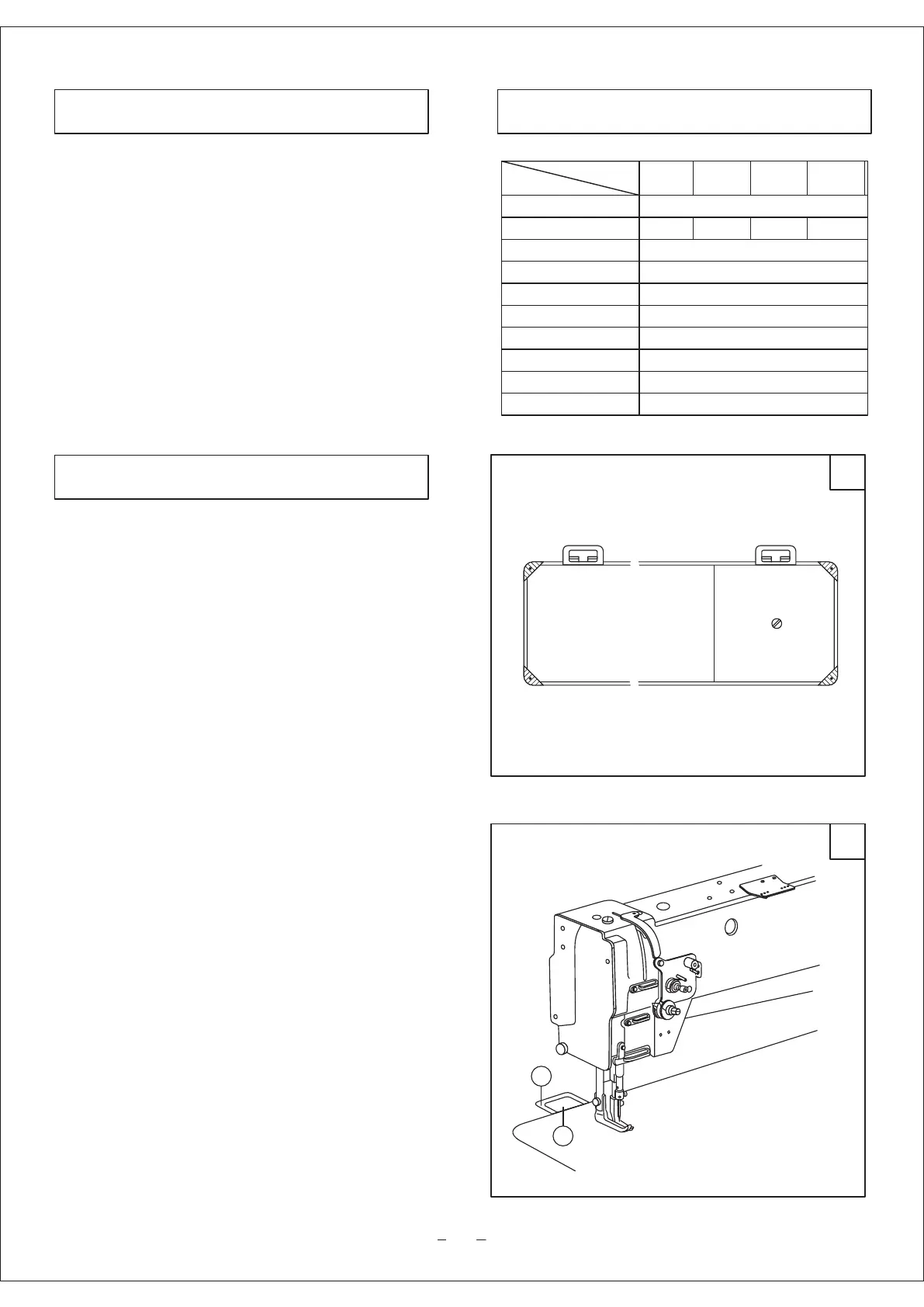

3.1.3 Installing the machine head (Fig.2)

Set the hinge A onto the hinge socket B on the table, then turn

the machine head freely until it is seated on the frame of table

cutout

3. Installation and preparation

GC20606

L18-D2T

/HL18-D2T

GC20606

-1L18-D2T

/-1HL18-D2T

GC20606

-D2

GC20606

-1-D2

1800spm1200spm 1200spm

Loading...

Loading...