-12-

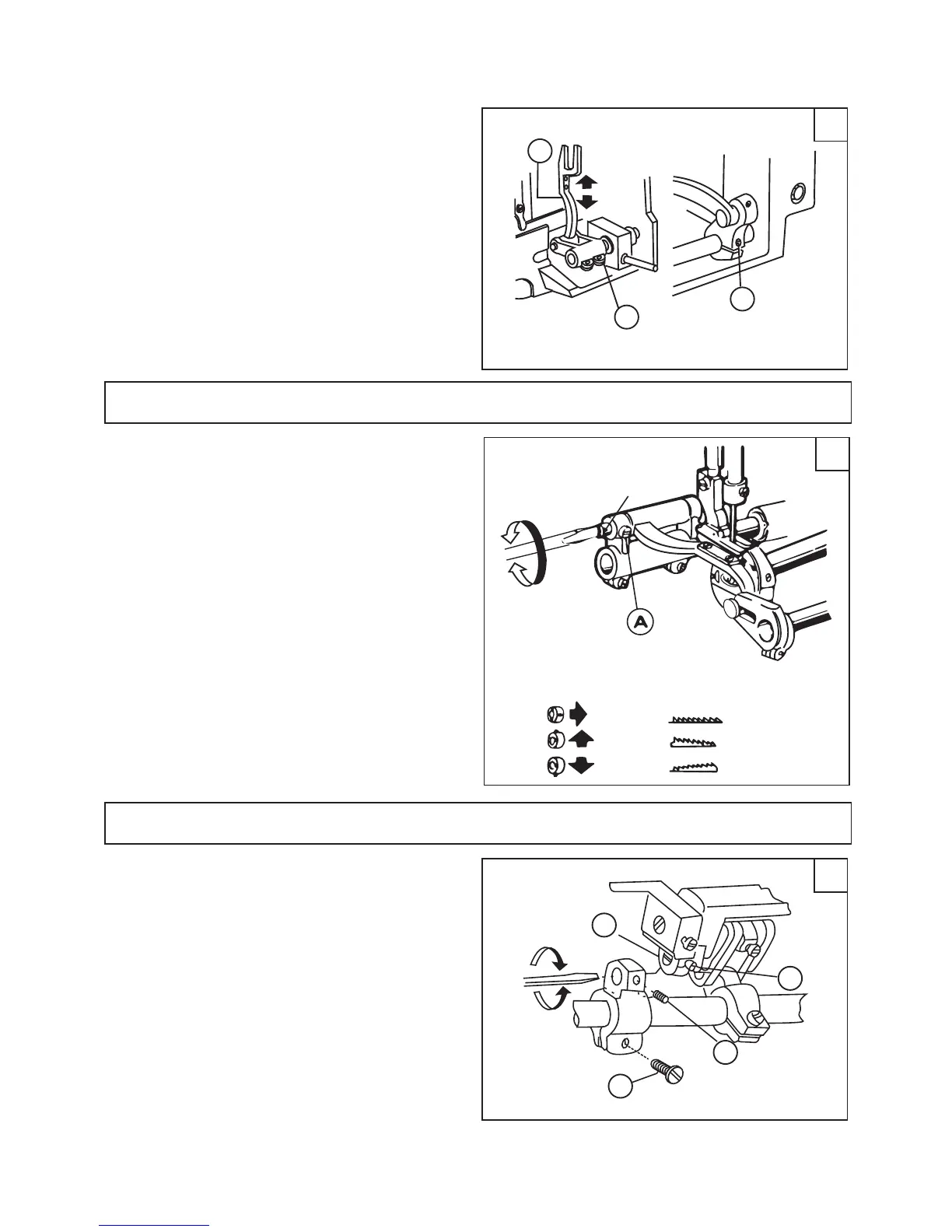

24.Feed dog horizontal Adjustment (Fig.30)

To adjust the position of feed dog, move feed

dog to the front end of throat plate. Loosen Screw

A (See Fig.29b), move feed dog support B in the di-

rection shown by arrow to adjust After adjustment

tighten Screw A.

Feed dog is 0.8~1.2mm above the surface of

throat plate horizontally.

When sewing condition requires tilting, adjust

like this:

loosen Screw A

Press against the slot of eccentric shaft with a

screwdriver to turn eccentric shaft left and right.

Tighten Screw A.

The front of feed dog is higher, which can pre-

vent perckering and no skipping.

The front of it is lower, which can prevent

material sliding and no breakage of bobbin thread.

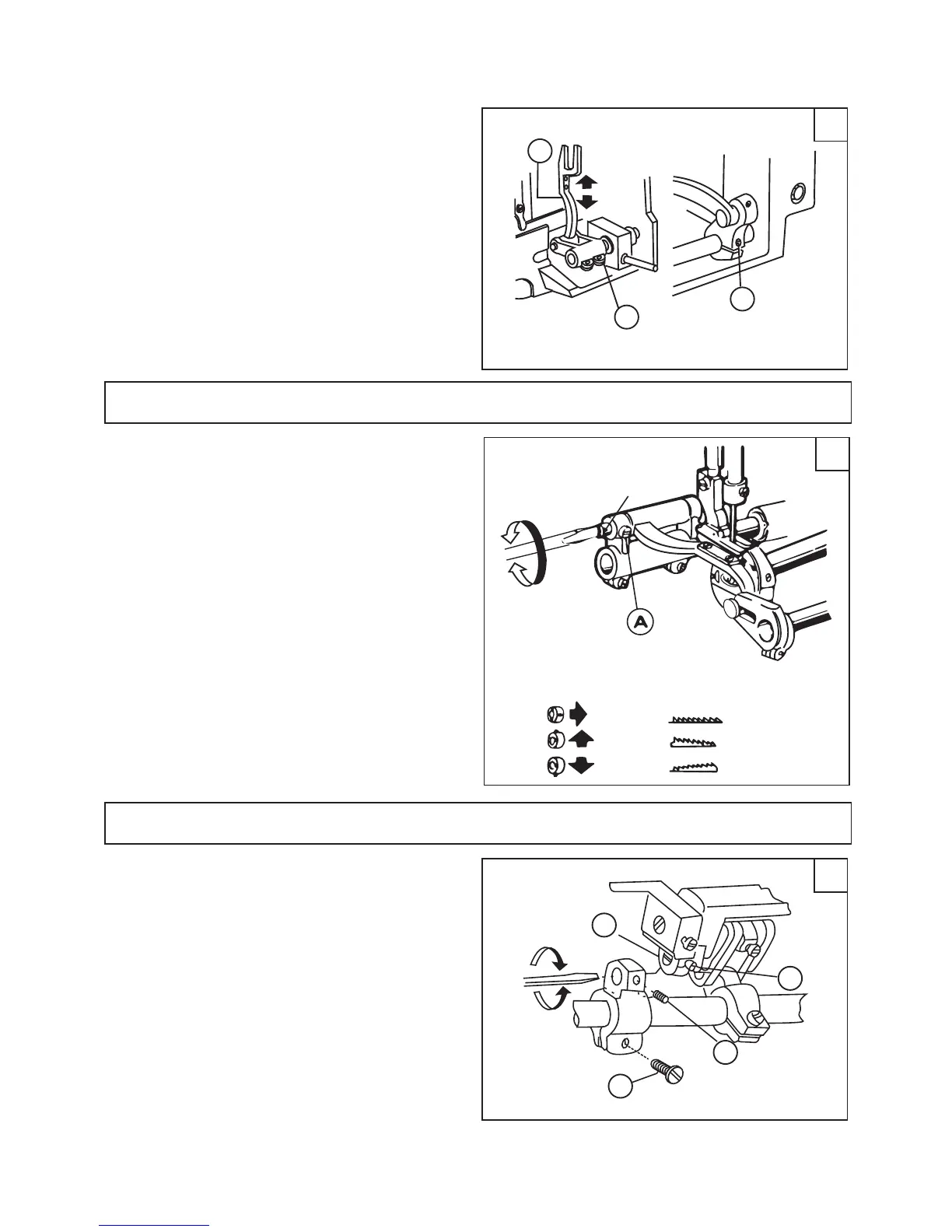

25.Stitch length error adjustment (Fig.31)

Loosen Screw (A) and (B), take out the link pin,

and loosen Screw (C) to adjust Cam (D) with a screw-

driver through the crank hole.

Turn right: forward stitch length shorten reverse

stitch length enlarged;

Turn left: forward stitch length enlarged reverse

stitch length shorten.

29

a

B

A

b

C

30

Eccentric shaft mark position

Mark

Feed dog

Horizontal

Above

Under

Standard

The front up to the max

Thefrontdowntothemax

31

B

A

C

D

Loading...

Loading...