-16-

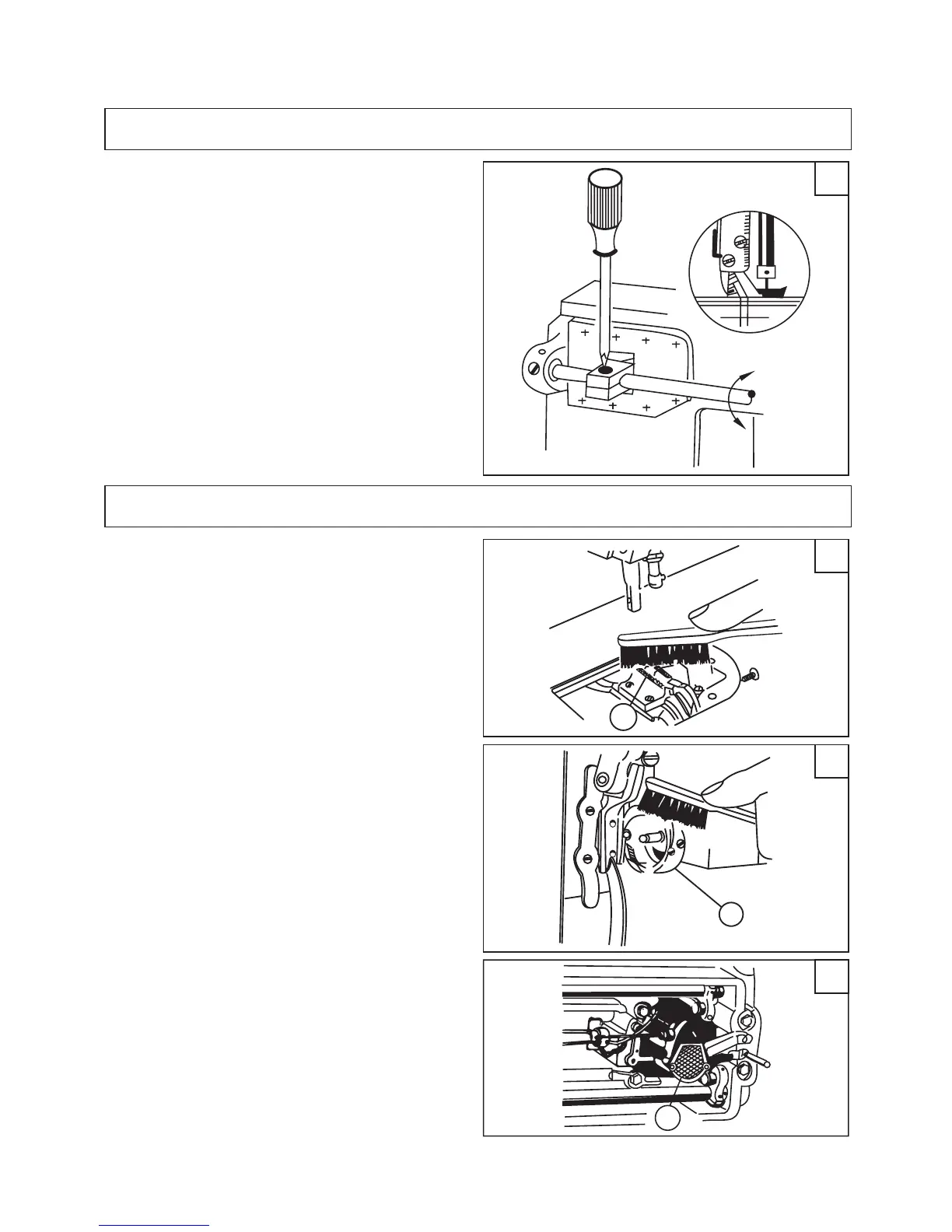

31.Adjusting the clearance between presser foot and follow presser foot (Fig.4

In sewing operation, for prevent the follow pre-

sser foot from striking on presser foot at the end of

feeding, a proper clearance C of approx. 1mm should

be maintained between them.

When the clearance is too small or too big nec-

essary to adjust, loosen the crank clampin screw

and turn down the needle bar shaft, then the follow

presser foot move near the presser bar, and note the

needle and the needle hole center ofeed dog, see

the figure if the needle is off the hole center, then

loosen feed crank set screw, move the feed dog to

the right position. After the adjustment, tighten the

set screw. For the right and left position, to loosen

screw (A) to obtain.

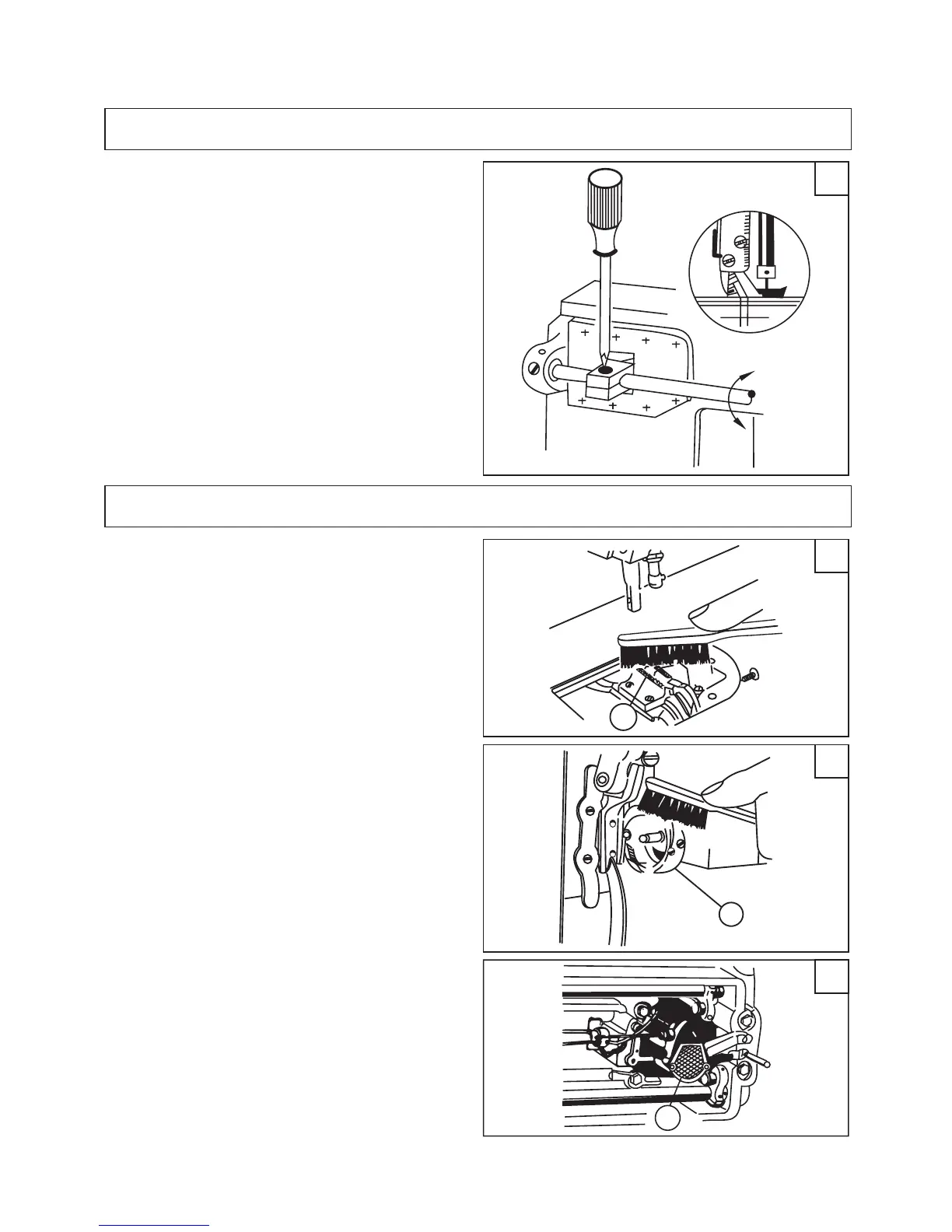

31.Periodical cleaning (Fig.41、42、43)

Clean the feed dog the rotating hook, the bobbin

case, the oil pump filter screen and the like perodically

according to customer s usage.

1.Cleaning the feed dog

Remove the throat plate, clean off all the dust

and lint on the slit of the feed dog , the installing the

throat plate.

2 Cleaning the rotating hook

Clean off all the dust around the rotating hook,

and clean the bobbin case with soft cloth.

3 Cleaning the oil pump filter screen (Fig.46)

Take off the oil filter, clean off the dust of filter

screen with gasoline.

41

A

42

A

43

A

40

C

Up

Down

Loading...

Loading...