10.Trial running

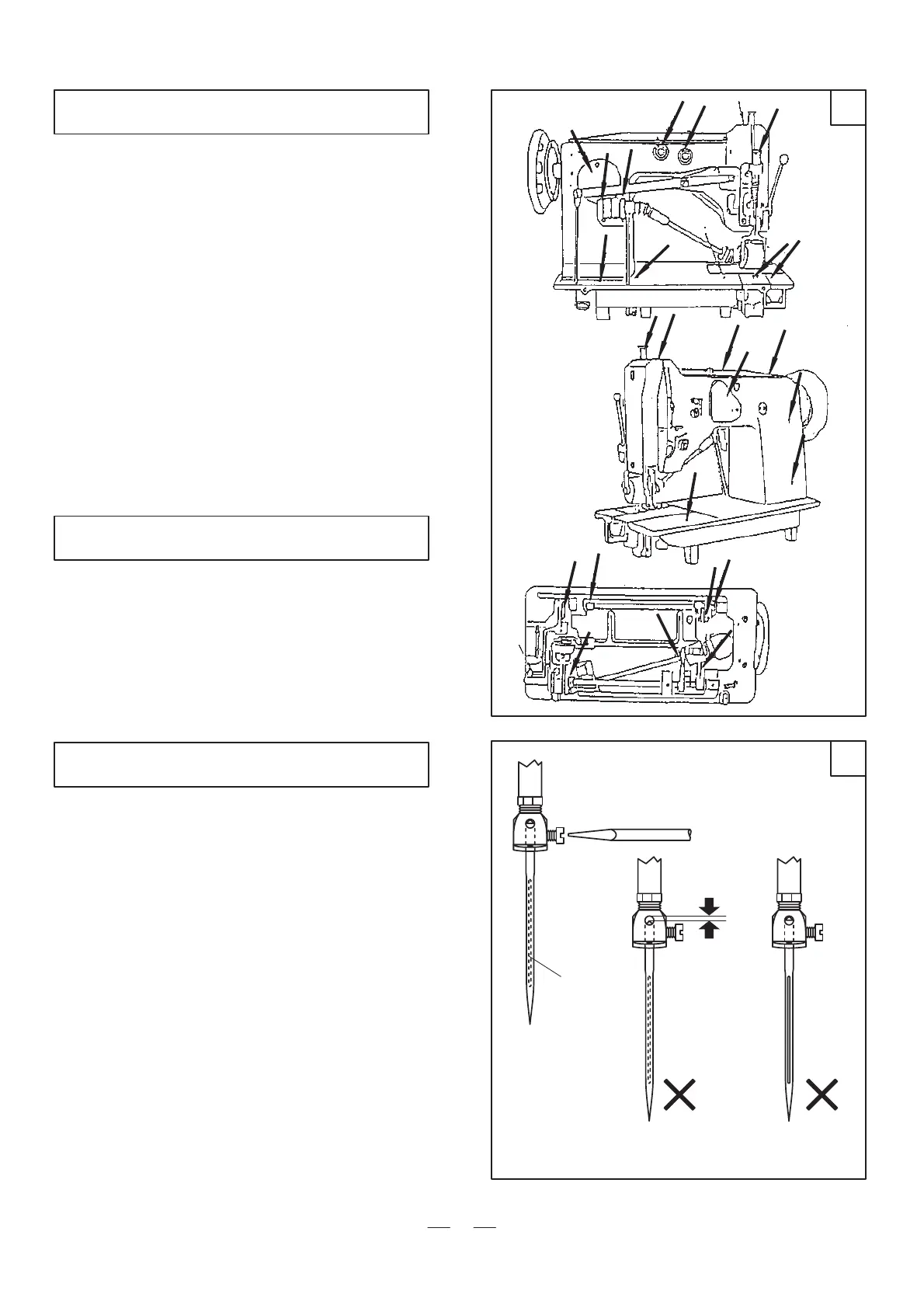

9.Lubrication (Fig.6)

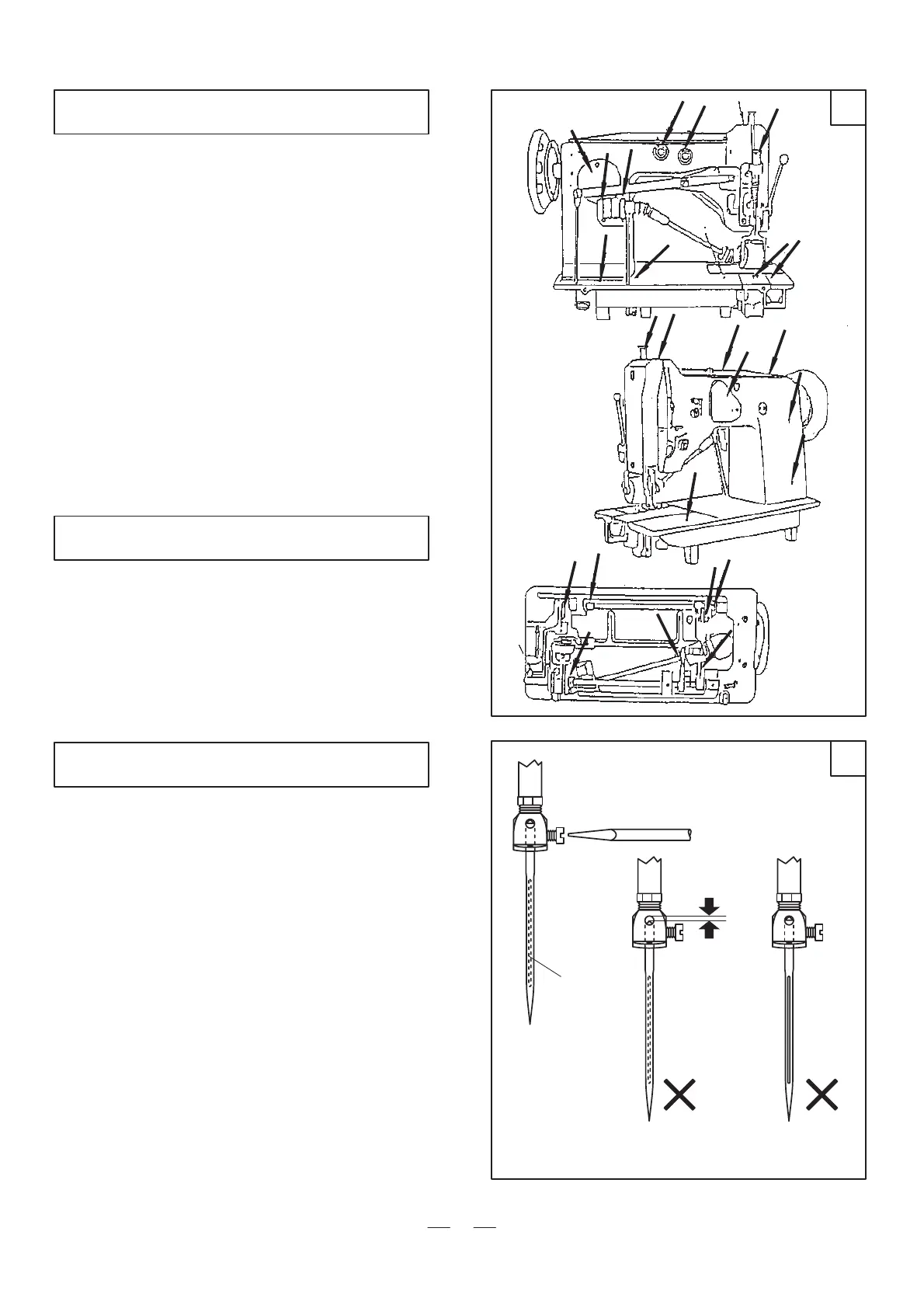

11.Installing the needle (Fig.7)

7

3

6

The machine must be oiled at the places with red

mark after the work is over every day. After

lubrication, please run 1 or 2 minutes.

.

Trial running is required when new machine is put

into use or use again after storing quite long time.

First uninstall the rubber plug above the machine

head and face plate and oiled by hand, then lift the

presser foot and run the machine at a low speed of

300~400s.p.m for 30 minutes, then increase the

speed gradually. After one month, please choose the

suitalble speed according to the sewing work. .

Turn the balance wheel to lift the needle bar to its

highest position, loosen the needle set screw, and

make the needle groove to the left side of the

operator, then fully insert the needle shank until to

the bottom of the needle bar socket, tighten the set

screw. .

.

Note: Insufficient insertion (Fig. b) or the needle

groove facing to the operator (Fig.c) is incorrect.

Clearance

The groove

left ward

a

b

c

Loading...

Loading...