NINA-W1 series - System integration manual

UBX-17005730 - R11 Handling and soldering Page 45 of 55

C1 - Public

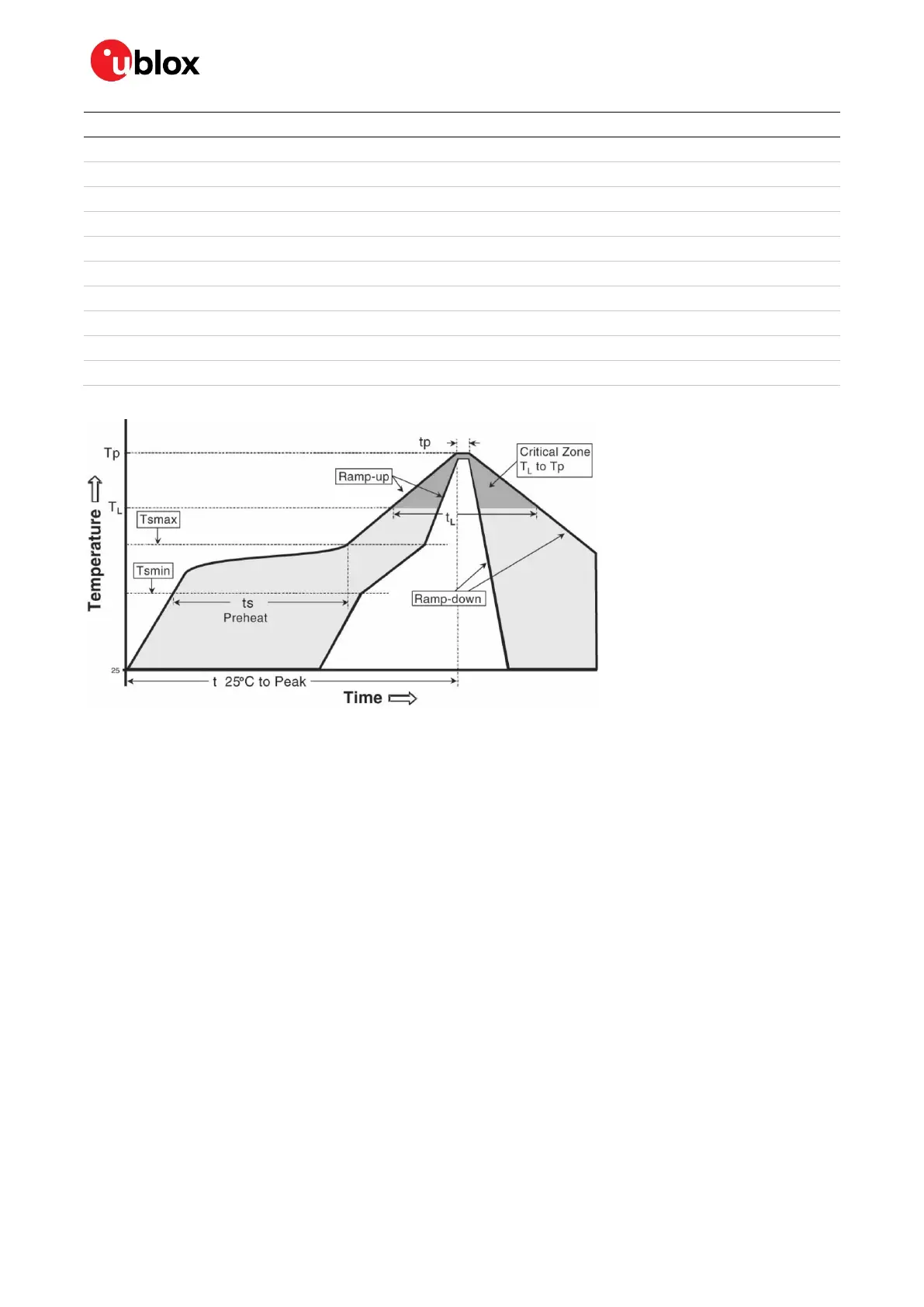

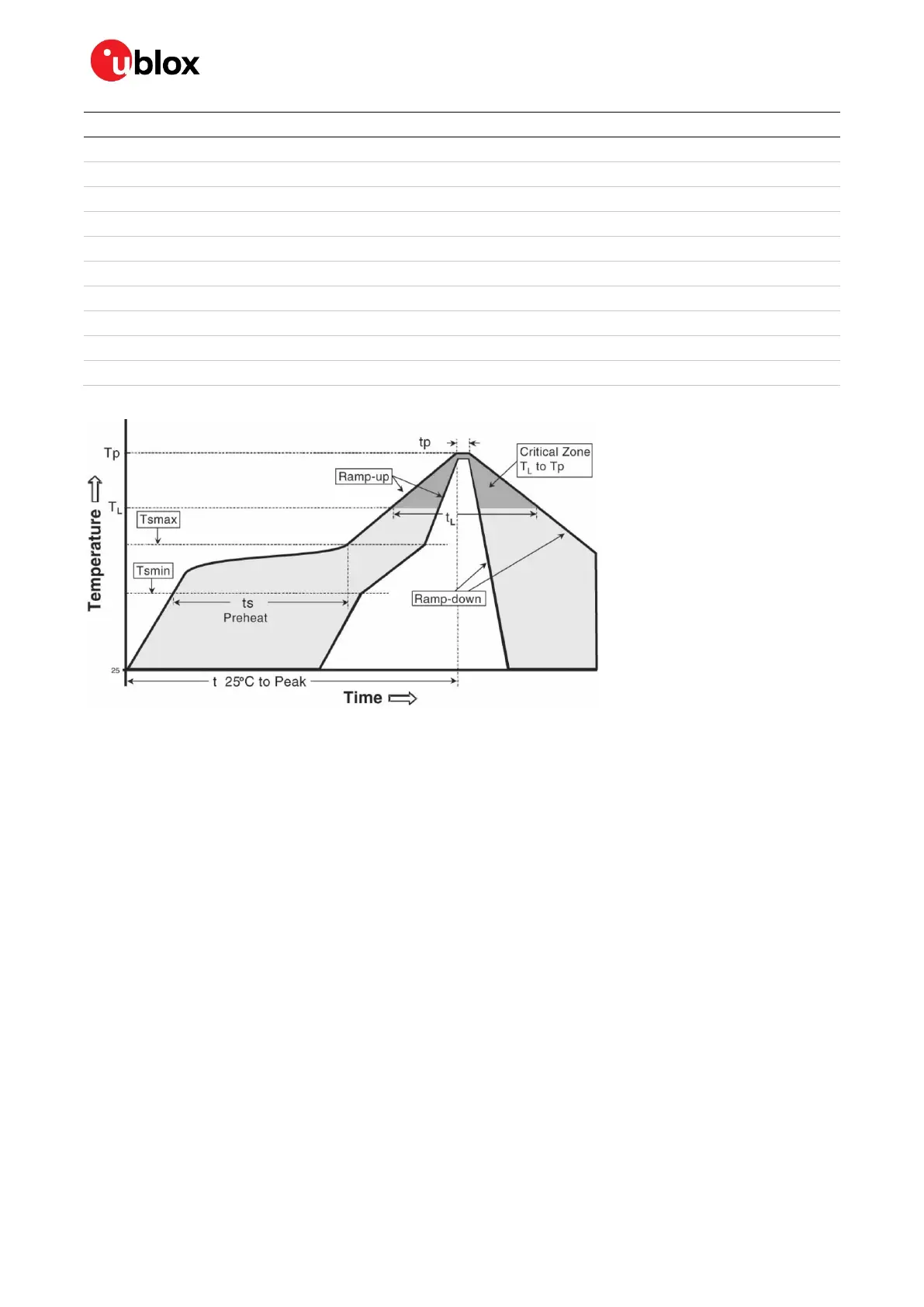

Process parameter Unit Value

Pre-heat Ramp up rate to T

SMIN

K/s 3

T

SMIN

°C 150

T

SMAX

°C 200

t

S

(from +25 °C) s 150

t

S

(Pre-heat) s 60 to 120

Peak T

L

°C 217

t

L

(time above T

L

) s 40 to 60

T

P

(absolute max) °C 245

Cooling Ramp-down from T

L

K/s 4

Allowed soldering cycles - 1

Table 6: Recommended reflow profile

Figure 30: Reflow profile

Lower value of T

P

and slower ramp down rate (2 – 3 °C/sec) is preferred.

After reflow soldering, optical inspection of the modules is recommended to verify proper alignment.

⚠ The target values given in Table 6 should be regarded as general guidelines for a Pb-free process.

Refer to JEDEC J-STD-020C standard for further information.

4.3.2 Cleaning

Cleaning the modules is not recommended. Residues underneath the modules cannot be easily

removed with a washing process.

• Cleaning with water will lead to capillary effects where water is absorbed in the gap between the

baseboard and the module. The combination of residues of soldering flux and encapsulated water

leads to short circuits or resistor-like interconnections between neighboring pads. Water will also

damage the sticker and the ink-jet printed text.

• Cleaning with alcohol or other organic solvents can result in soldering flux residues flooding into

the two housings, areas that are not accessible for post-wash inspections. The solvent will also

damage the sticker and the ink-jet printed text.

• Ultrasonic cleaning will permanently damage the module, in particular the crystal oscillators.

For best results, use a "no clean" soldering paste and eliminate the cleaning step after the soldering

process.

Loading...

Loading...