-14-

4.4 Stopping

Close the vacuum valve (A), and quickly open the leak valve (B), and turn the pump

switch off. After the intake side has returned to atmospheric pressure, close leak

valve (B), and seal the intake side. (Refer to Fig. 4.)

Failure to do so may result in burns. The pump becomes hot (40-80ºC) during

operation. After stopping, do not touch the motor or pump until they have cooled.

4.5 Backflow prevention device

This pump is fitted with an oil backflow prevention device. It is effective for preventing

the oil from back flowing when the pump is stopped. (It is not a gas backflow

prevention device.)

The backflow prevention device uses the oil pressure inside the pump to return the

internal pressure to atmospheric pressure when the pump is stopped and to close

the valve directly below the intake.

The backflow prevention device does not guarantee to do this 100%. In the case that

the internal pressure is not returned to atmospheric pressure when the pump is

stopped, approximately 400 ml of oil will enter the vacuum chamber in a short time.

Also, even if the internal pressure is returned to atmospheric pressure when the

pump is stopped, the pressure in the vacuum chamber will return to atmospheric

pressure in a short time.

In addition to installing the vacuum valve (A) and leak valve (B) between the vacuum

chamber and pump as shown in Fig. 4., ensure that there is more capacity between

the pump and vacuum chamber that the amount of the oil backflow.

4.6 Thermal protector

An automatic-recovery type thermal protector is built-in to this pump. This

automatically breaks the circuit of the motor power supply and prevents the motor

from being damaged if the pump stops rotating during operation or if an over current

flows to the motor due to an overload.

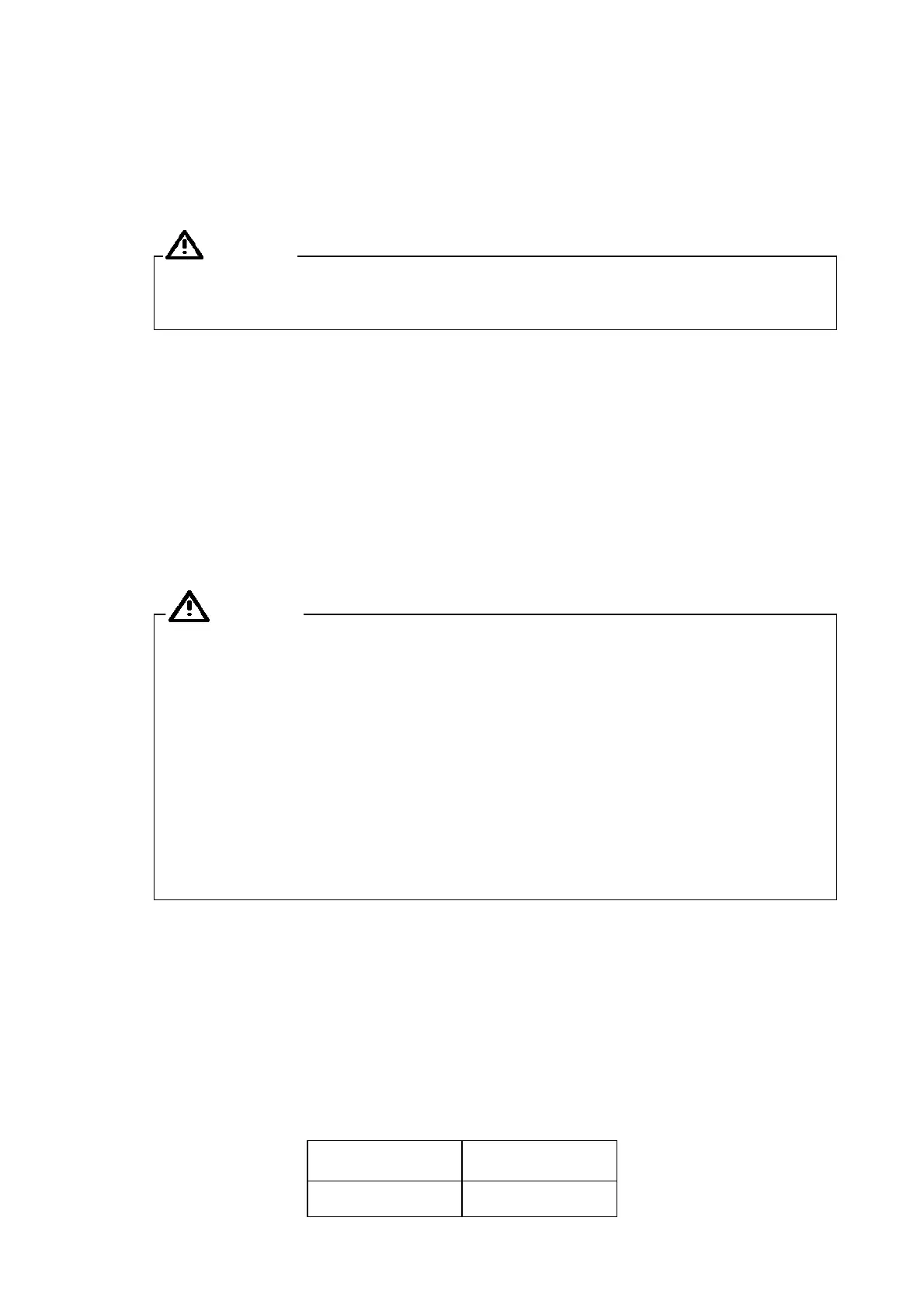

Table 4 Thermal protector characteristics

Operating

temperature

Recovery-possible

temperature

130 ºC±5 ºC 83 ºC±15 ºC

Caution

Warning

Loading...

Loading...