37

Maintenance instructions

ENGLISH

DANGER!

The conversion for the operation of

the boiler with a type of gas other

than that specically required in the

order, must be performed by pro-

fessionally qualied personnel, in

compliance with the standards and

regulations in force.

The manufacturer cannot be held

liable for any damage resulting from

a conversion operation that is incor-

rect or not performed in compliance

with the laws in force and/or with the

instructions given.

ATTENTION!

After performing the conversion for

the operation of the boiler with a type

of gas (e.g. propane gas) other than

that specically requested when or-

dering, the appliance will only work

with this new type of gas.

ATTENTION!

Indications for propane gas-fired

appliances

Make sure that the gas tank has been

deaerated before installing the appli-

ance.

For state-of-the-art deaeration of the

tank, contact the LPG supplier or a

person qualied in compliance with

law.

If the tank has not been profession-

4.3 - ADAPTATION

TO THE USE OF OTHER GAS

Gas Conversion

The boilers are produced for the type of gas speci-

cally requested upon ordering.

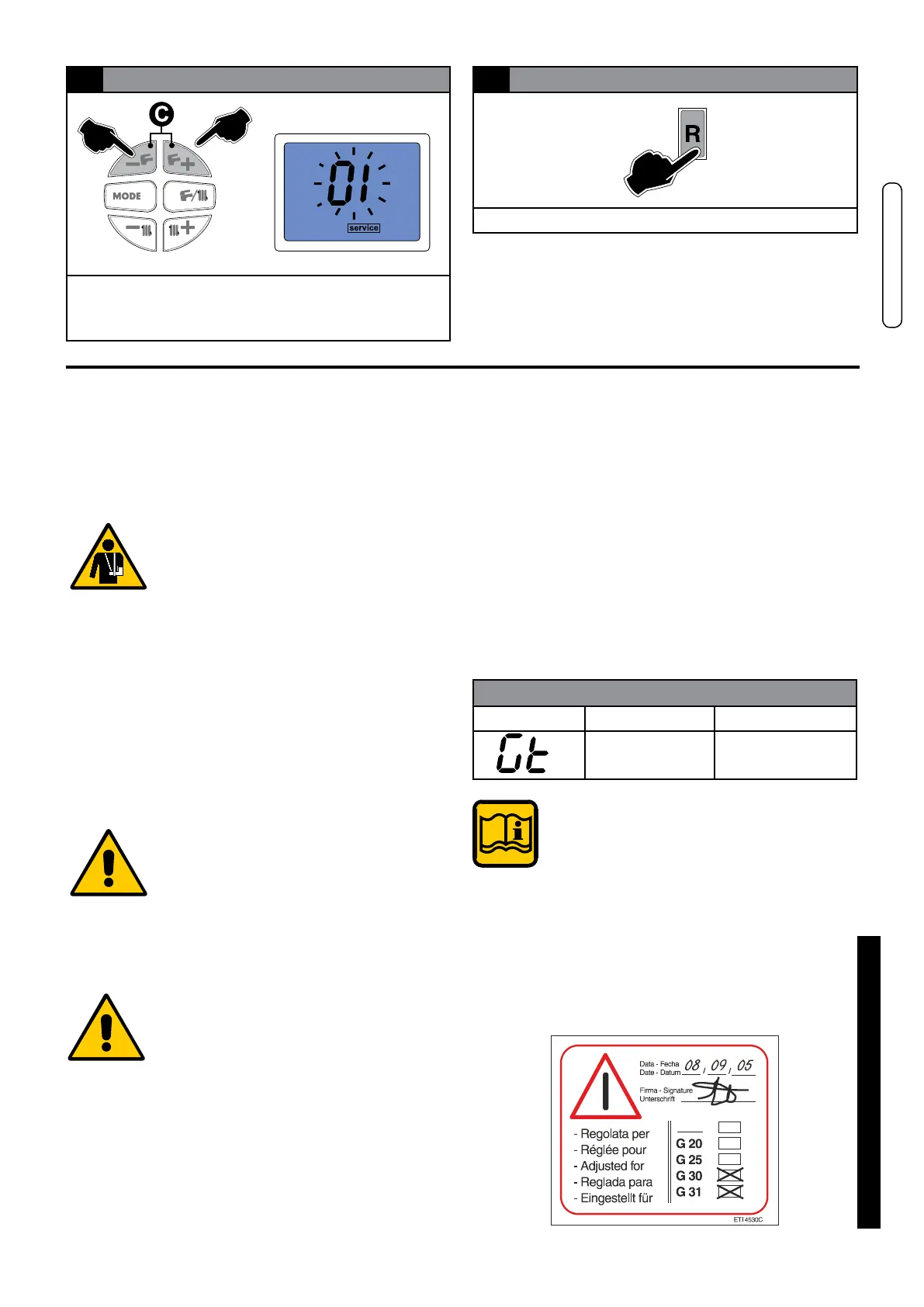

EDITING THE VALUE

Press the key (C+) to access the parameter,

the parameter value ashes.

Correct the value with the keys (C+ or C-)

4 CONFIRM VALUE

Press key D

FA PARAMETERS (UNIT 1) par 4.2

CODE METHANE PROPANE

0 1

4 5

In order to change the gas one must change

the Factory parameter:

ally deaerated, ignition problems could arise.

In that case, contact the supplier of the LPG tank.

Once the Gt parameter has been

edited one must perform the GAC

automatic calibration (Gas Adaptive

Calibration) Chapter 4.3.1

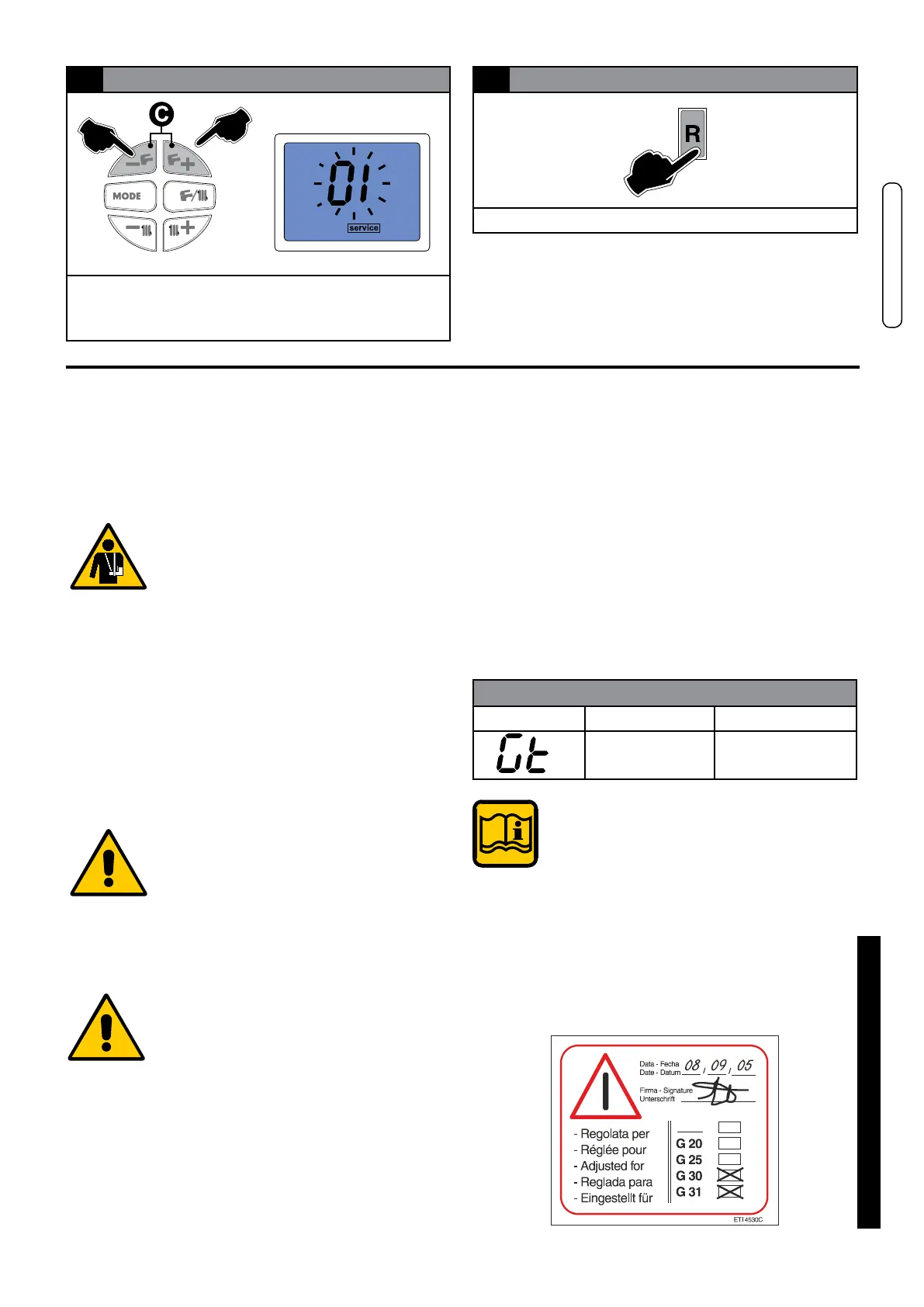

EXAMPLE OF COMPILATION

- when the conversion is complete, ll in the

information required on the label supplied in

the documentation envelope and apply it next

to the technical data label of the boiler.

NOTE!

Further details in the section

‘‘Technical Information’’ on the

boiler page of the www.unicalag.it

website

Loading...

Loading...