Operation

WPP 15 E | Version 1.02 11

Step 1: position the support blocks on the press table.

Step 2: press the four pins in the support blocks down

on each side so they are fully inserted in the

press table.

This prevents the support blocks from slipping or tilting

during processing.

10.3 Adjusting the horizontal working position

Step 1: align the workpiece so that it is horizontal to the

hydraulic cylinder.

As a result, it cannot tilt during hydraulic cylinder pro-

cessing.

10.4 Aligning hydraulic cylinders

The hydraulic cylinder can be manually moved to the

desired position over the workpiece. For this purpose, it

can be moved towards the left or right.

10.5 Building up pump pressure

Step 1: move the switching valve to the right-hand posi-

tion to access the hydraulic cylinder for filling.

Step 2: move the pump lever and the pedal up and

down until the stamp comes into contact with the

workpiece. Fill the hydraulic cylinder with oil.

Step 3: continue to pump until the required pump pres-

sure has built up. For this purpose, monitor the

pressure gauge.

The pump pressure can also be built up using the pneumatic

foot-operated pump.

For this purpose, operate the pneumatic foot-operated

pump and proceed as described for the pump lever un-

til the required pressure has been built up.

10.6 Marking the cylinder limit position

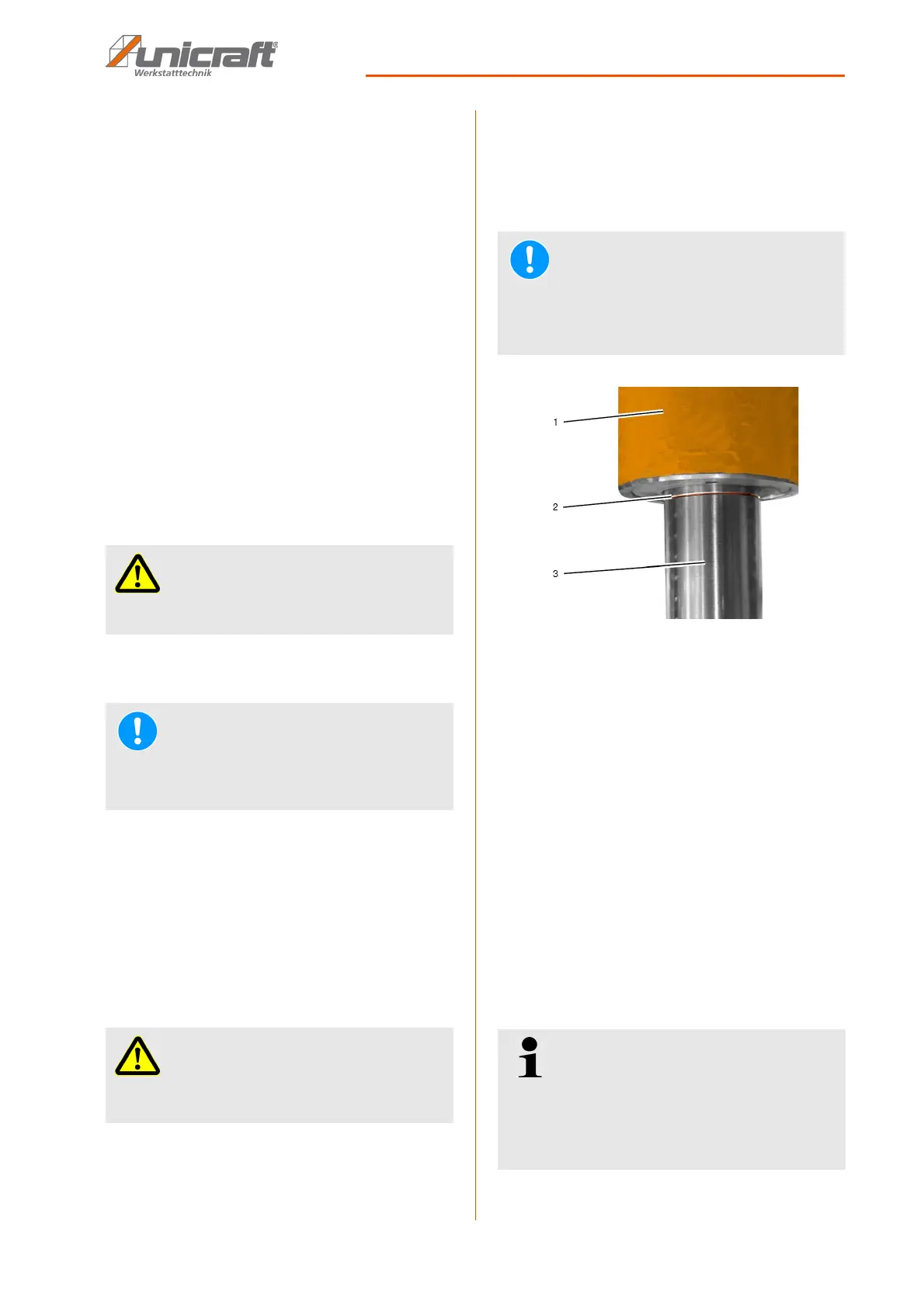

Fig. 9: Cylinder limit position mark on the piston rod

1 - Cylinder

2 - Limit position mark on the piston rod

3 - Piston rod

If the marking on the piston rod [2] becomes visible dur-

ing the pressing process, the pressing process must be

terminated to prevent potential damage to the cylinder.

In the event of non-observance and continued pumping

the cylinder will be damaged with the result that the cyl-

inder may no longer retract correctly.

Retract the cylinder if the pressing process was insuffi-

cient up to the mark (see section 10.7). In this case, ele-

vate the press table and repeat the pressing process

(from section 10.2).

10.7 Retracting hydraulic cylinders

IMPORTANT!

Make sure the workpiece has been centred under

the piston!

NOTE!

Monitor both the working area and the pressure

gauge during pressing to exclude potential damage

to the press or workpiece caused by overloads.

IMPORTANT!

- Do not exceed the press capacity!

- Do not use extensions for the pressure lever

NOTE!

Monitor both the work area and the piston rod during

the pressing process for the purpose of marking the

limit position to prevent potential damage to the cyl-

inders caused by overloads.

Tips and recommendations

The manufacturer has already configured the

retracting speed of the hydraulic cylinder. Modifica-

tions are required or permitted following mainte-

nance work or repairs only. For this reason, the

adjusting screw has been covered.

Loading...

Loading...