Installation

WPP 15 E | Version 1.02 9

The following parts of the hydraulic workshop press are

provided in disassembled condition in the cardboard

box:

- Crossbeam feet

- Press table

- Pump unit

- Pressure gauge

These parts must be assembled or converted and se-

cured with screws.

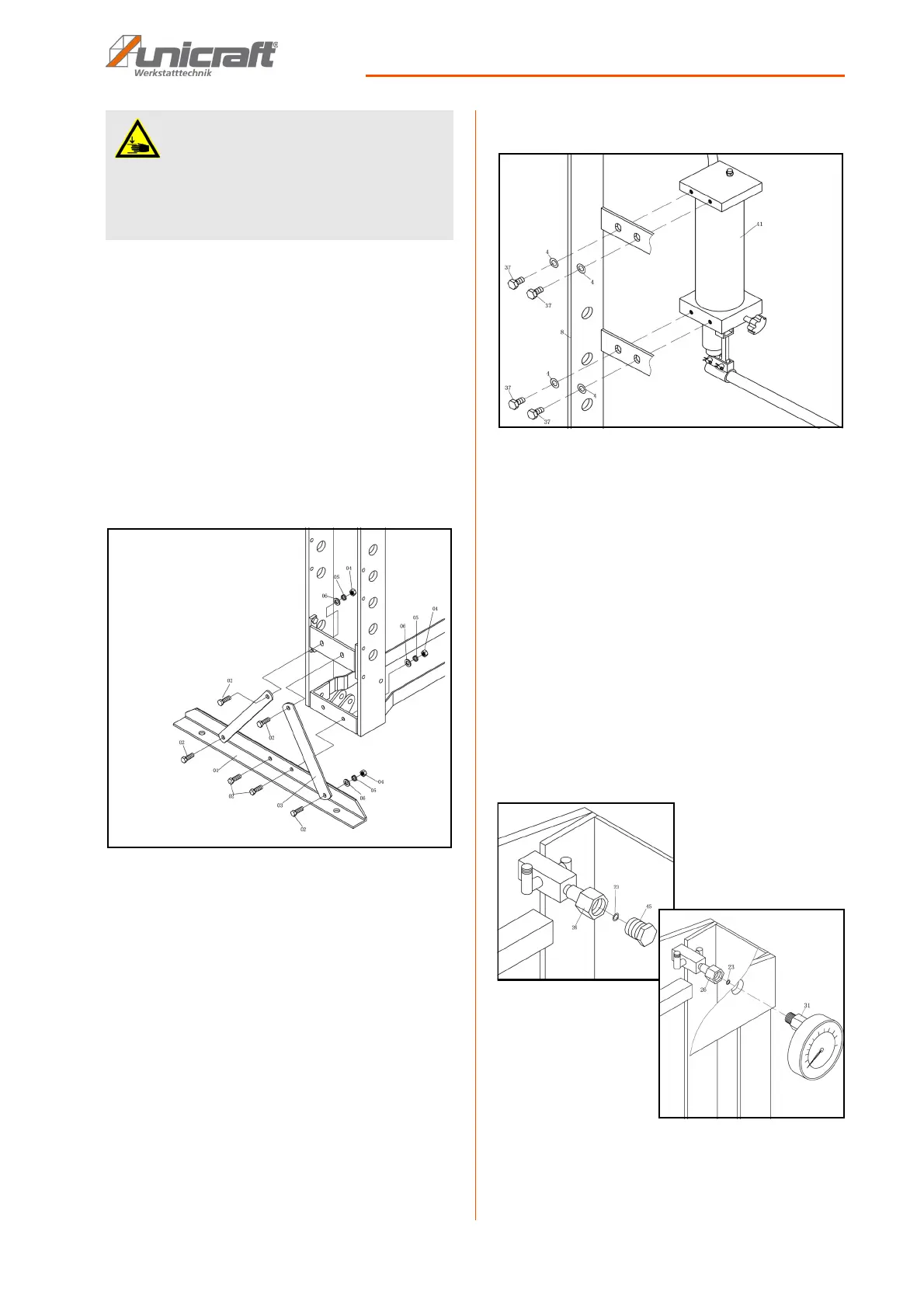

8.1 Installing crossbeam feet and press table

Fig. 6: Installing crossbeam feet

Step 1: secure the crossbeam feet and the two cross-

beams to both sides of the frame using the

screws, shims, spring washers and nuts (see

Fig. 6).

Step 2: insert the support bolts into the frame at the de-

sired height and secure them using the safety

splints. The position the press table onto the

support bolts in the frame.

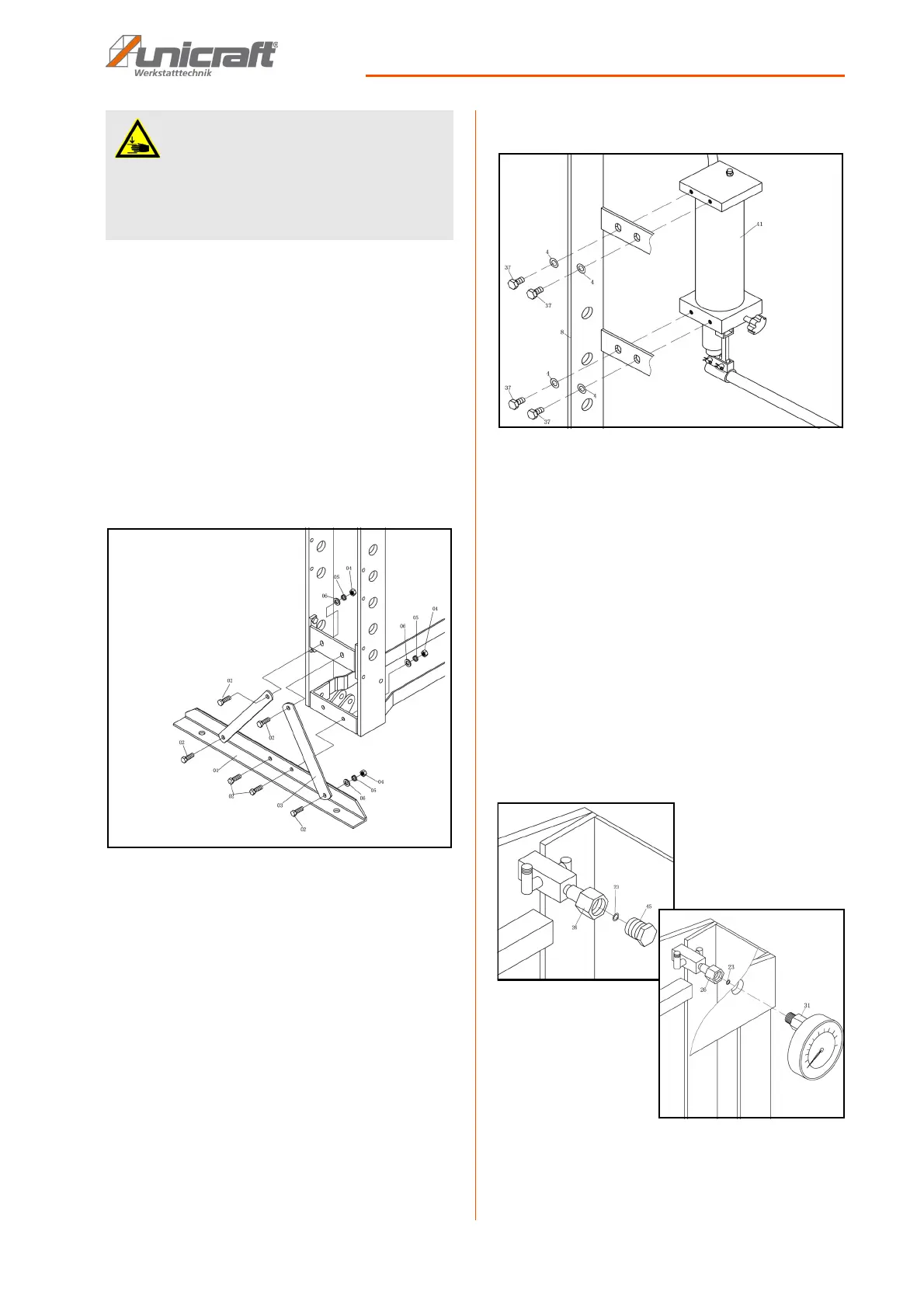

8.2 Installing the pump unit

Fig. 7: Installing the pump unit

Step 1: screw the pump unit onto the outside of the

frame using the screws and shims (see Fig. 7).

Step 2: install the pressure lines.

8.3 Installing the pressure gauge

The machine is delivered with a seal plug instead of the

pressure gauge to prevent escaping oil. Replace it with

the pressure gauge.

Step 1: remove the sealing plug and seal.

Step 2: securely fasten the pressure gauge and seal to

the distributor (see Fig. 8). The connection

must not leak to prevent escaping oil.

Fig. 8: Installing the pressure gauge

ATTENTION!

Risk of pinching!

Risk of injury to fingers and hands caused by incor-

rect installation work on the workshop press.

- Keep in mind the workshop press' weight. Ensure

stable supports and support equipment.

Loading...

Loading...