8 WPP 15 E | Version 1.02

Machine description

6 Machine description

Figures in these operating instructions may deviate from the

original.

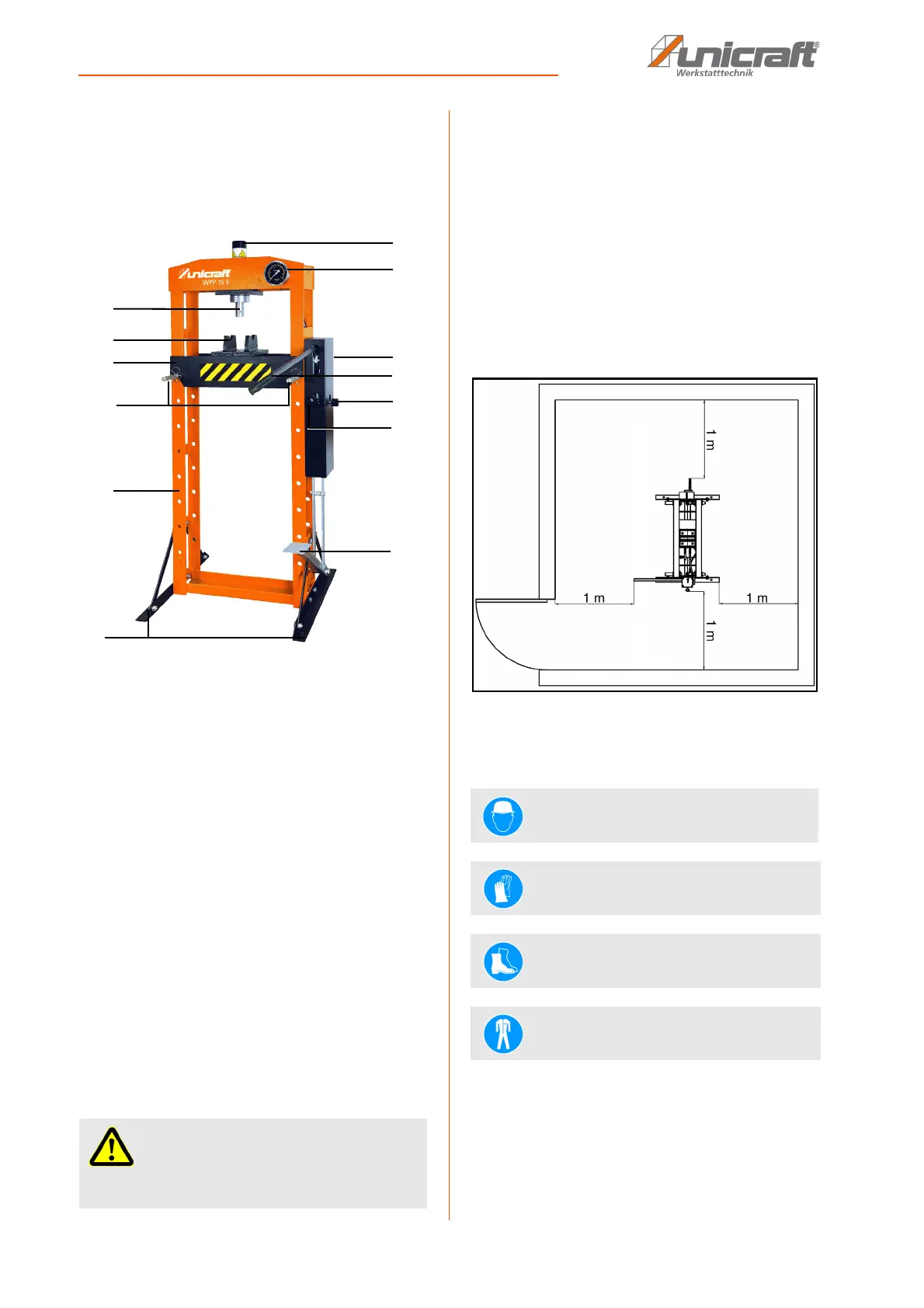

Fig. 4: WPP 15 E hydraulic workshop press

1 Hydraulic cylinder

2 Pressure gauge

3 Manual hydraulic pump

4 Pump lever for the manual hydraulic pump

5 Switching valve to move the hydraulic cylinder up/

down

6 Trigger valve

7 Pedal

8 Crossbeam feet

9 Frame

10 Press table support bolt

11 Press table

12 Support blocks

13 Stamp

6.1 Optional accessories

- Protective grille

- Pressure barb set

7Setup

The hydraulic workshop press must be set up and oper-

ated in dry, well-ventilated indoor areas only.

It must be positioned securely and set up on an even,

stable surface that is free from vibrations and be se-

cured using suitable ground anchors.

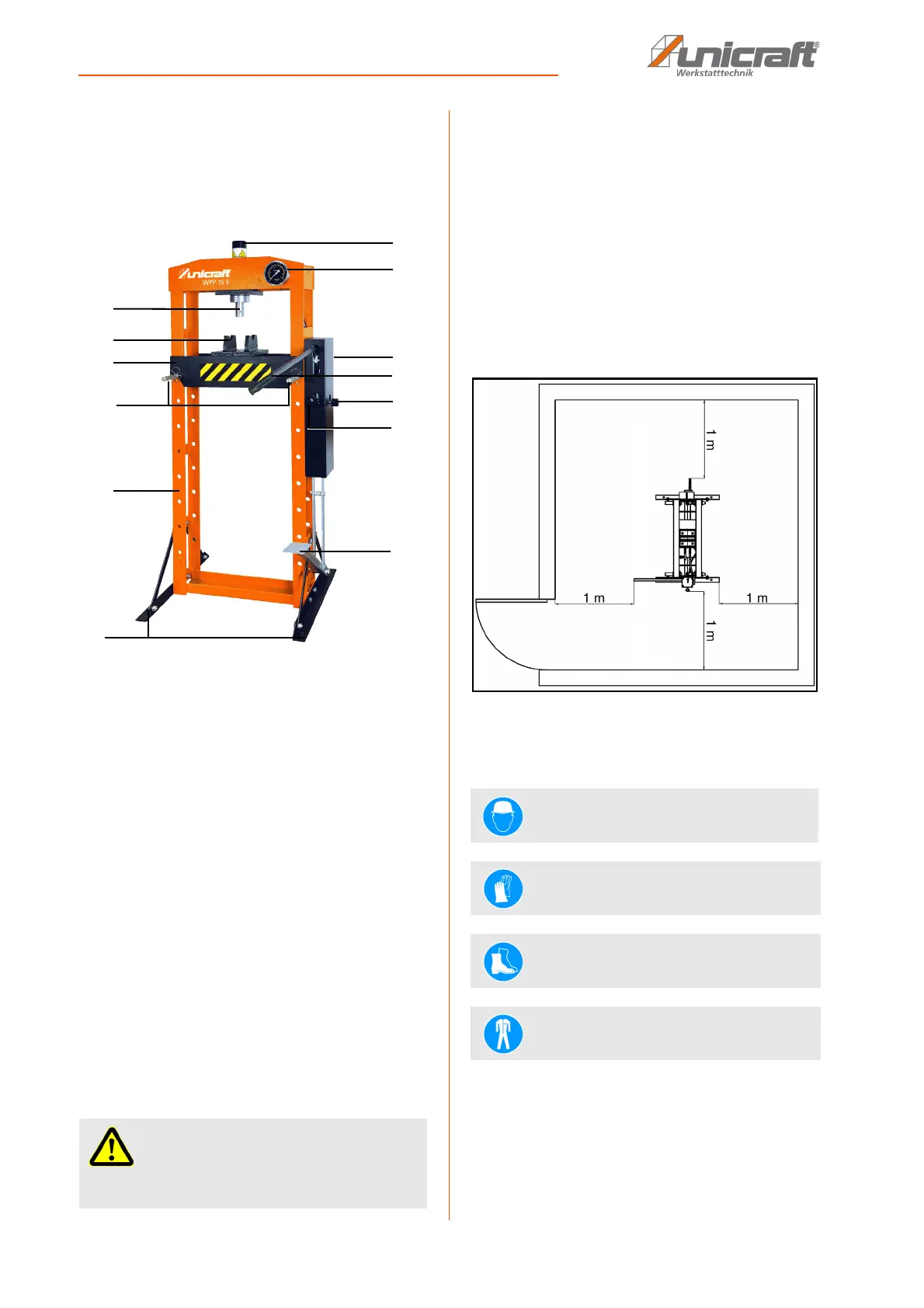

Make sure there is a sufficient amount of clearance, ap-

proximately 1 m clearance on each side (see Fig. 6) and

the work area is adequately lit.

Fig. 5: Correctly set up the hydraulic workshop press

8Installation

IMPORTANT!

Do not exceed the maximum pressure of 15 tons

when using the pressure barb set.

Wear head protection!

Wear protective gloves!

Wear safety shoes!

Wear protective clothing!

Loading...

Loading...