Maintenance and repairs

WPP 15 E | Version 1.02 13

11.2.1Visual inspection

11.2.2 Maintenance tasks

11.2.3Recommended processing materials

11.2.4Lubrication

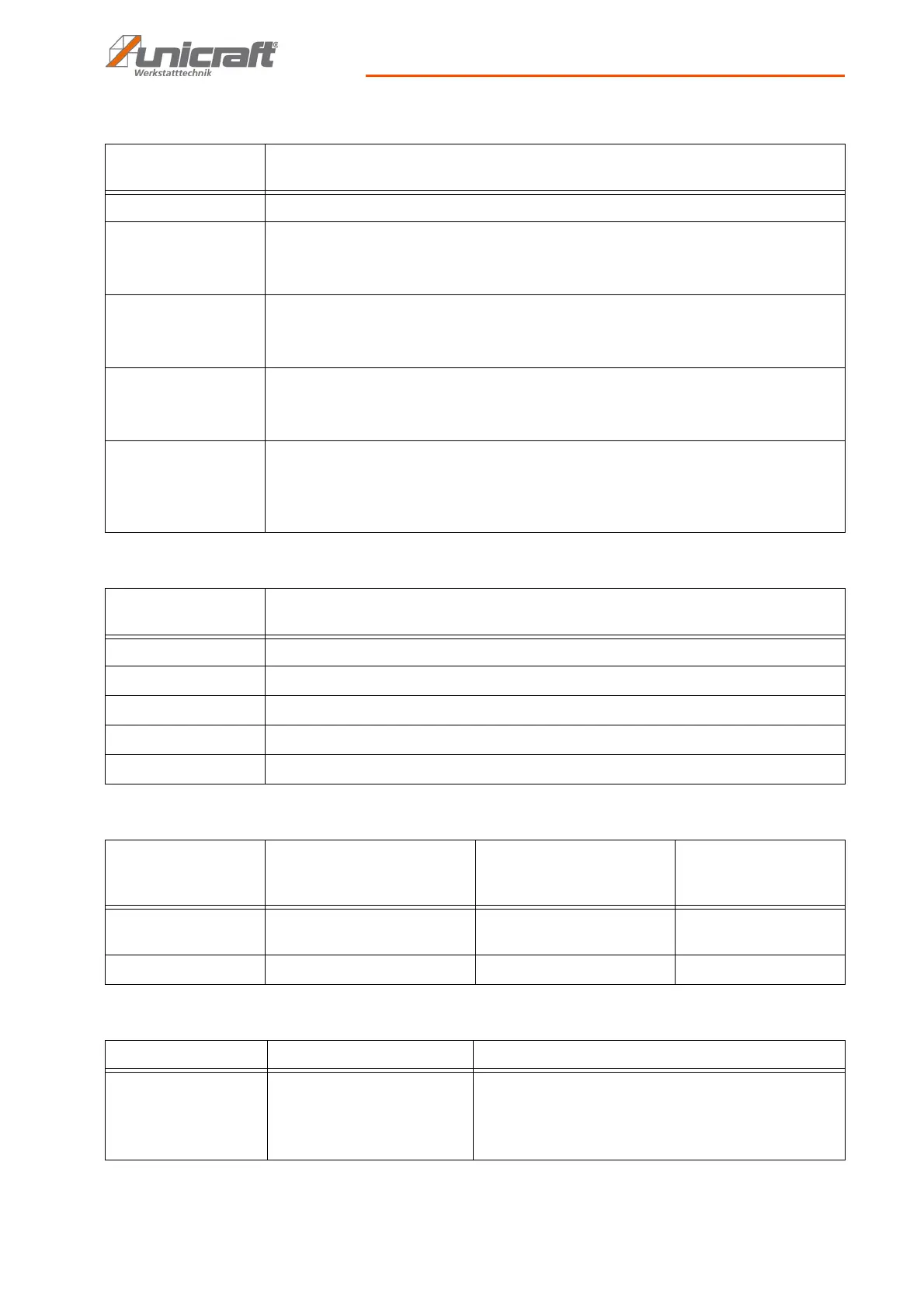

Maintenance intervals

and operating hours

Maintenance point

Daily Visual inspection of the hydraulic workshop press for dirt, clean if necessary

Weekly Visual inspection of the hydraulic workshop press, in particular the press table and support

bolts:

if necessary, replace damaged components or request repairs

Weekly Visual inspection of the hydraulic workshop press, in particular the functions of the hydrau-

lic components and checking for oil leaks (pump, hoses, cylinders, pressure gauge, etc.):

If necessary, replace damaged components

200 Functional inspection of the entire hydraulic workshop press to verify the machine com-

pletes all steps and operates correctly and safely:

If necessary, request repairs

Annually Have the hydraulic pipes and connections checked by an authorised person. In the event

of increased usage periods, frequent or increased pressure pulses or severe external influ-

ences the machine must be checked once every six months.

If necessary, have damaged pipes replaced.

Maintenance intervals

and operating hours

Maintenance task

200

Lubricate the hydraulic workshop press (all moving parts, bearings and guides).

300 Change the hydraulic oil.

When necessary Vent the hydraulic system.

When necessary Top up hydraulic oil and then vent the hydraulic system.

6 years Have hydraulic lines replaced. Every two years in the event of increased usage periods.

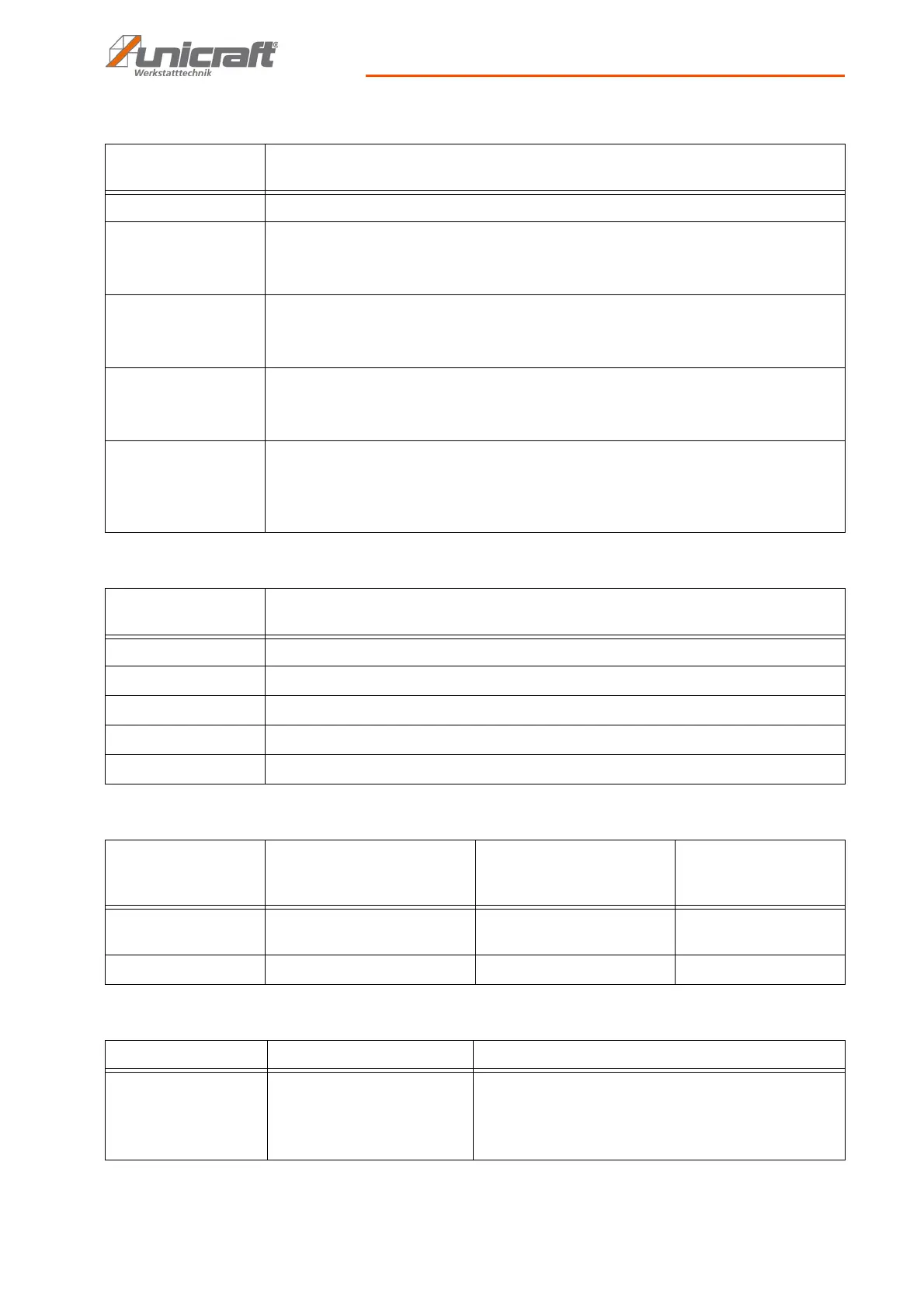

Processing material Specification Manufacturer/type

(non-binding recommenda-

tion)

Quantity

Hydraulic oil ISO 32

Viscosity from 22 to 25 mm²/s

OMV HYDRAL 32

Grease SO XM 2 OMV SIGNUM M 283 As required

Machine component Lubrication point Lubrication medium

Manual hydraulic

pump

Stamp

Shaft on the switching valve

Grease:

Apply grease to the listed components using a greased

brush. Remove excess lubricant using a dry and lint-free

cloth.

Loading...

Loading...