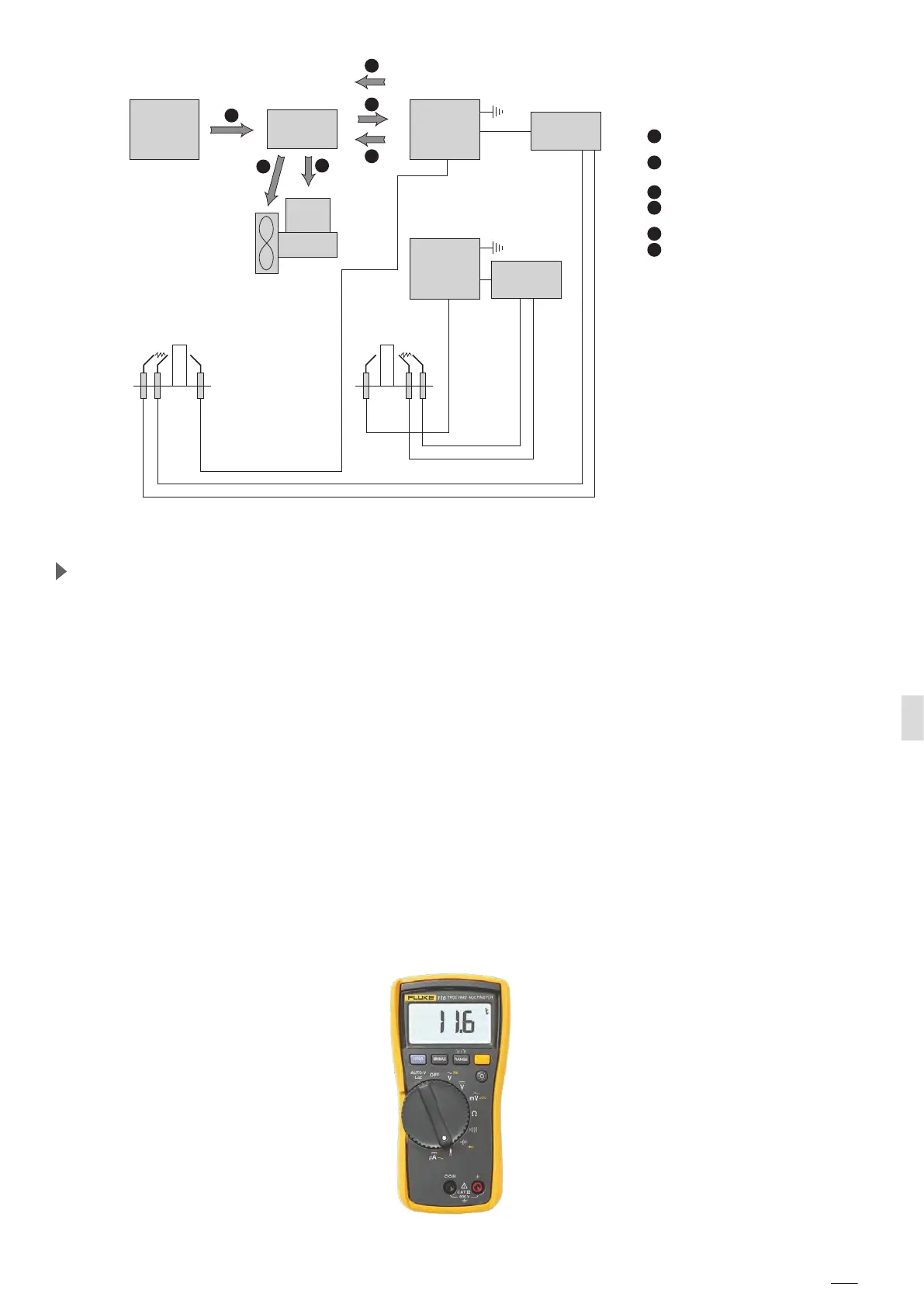

FLAME

CONTROL

BOARD 1

IGNITER

1

IGNITER

2

FLAME

CONTROL

BOARD 2

CONTROL

BOARD

HEAT DEMAND

GAS

VALVE

1

1

START IGNITION CYCLE

+ SPARK IGNITION

2

BLOWER POWER

CONTROL SPARK

3

4

GAS VALVE OPENING

5

6

2

3

5

6

4

POWER

BOARD

AC-DC

120V AC

Ignition sequence for US system

Maintenance of the electric part of the gas system

The US flame control board has an automatic diagnostic system. During different working conditions

the flame control board shows multiple working status by means of multi-color LEDs:

■ Steady green light, good status/flame sensed;

■ Steady o

r

an

g

e

light, start up status;

■

Steady

red

light, stop/gas block status;

■ Flashing

green

light, working status with weak ionizing signal;

■ Flashing

orange

light, start up status with good ionizing signal;

■ Flashing

red

light, diagnostic stop status or parasitic flame current;

■ Green and orange alternating light, start up status with weak ionizing signal;

■ Red and orange alternating light, low/high voltage signal.

During the start up the system normally shows steady orange – flashing orange – steady green light.

The system attemps three startup cycles every 5 seconds. The US gas oven has 2 flame control boards that

work synchronized. The European flame control board does not use a diagnostic system.

■ Ionization current;

■ Blower speed;

■ Visual check of the harnesses of the ignition and flame detection cables and electrodes.

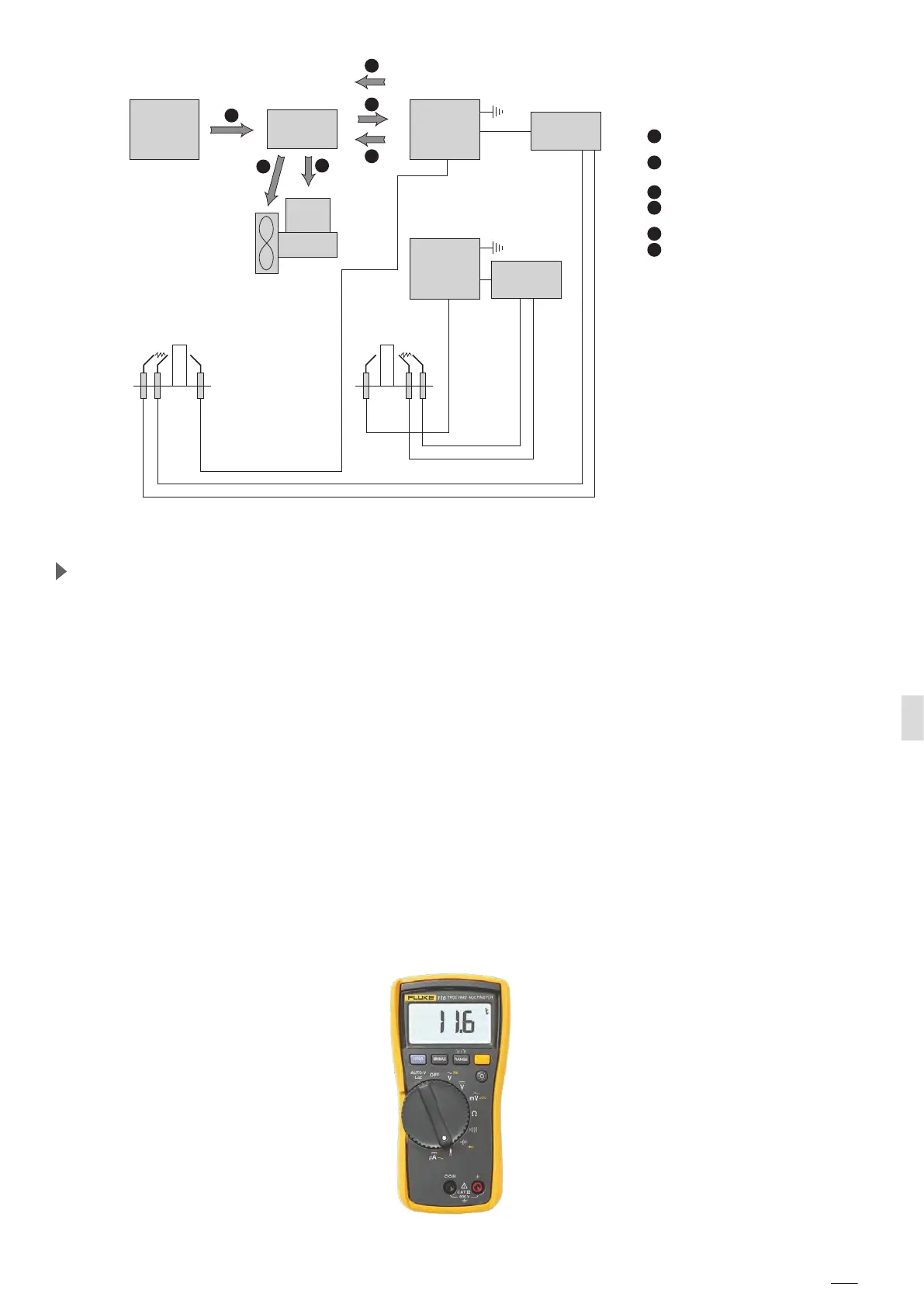

The suggested instrument to perform these measurements is the Multimeter model: Fluke 116, see .

Multimeter TRUE RMS FLUKE 116 with Microamps

Loading...

Loading...