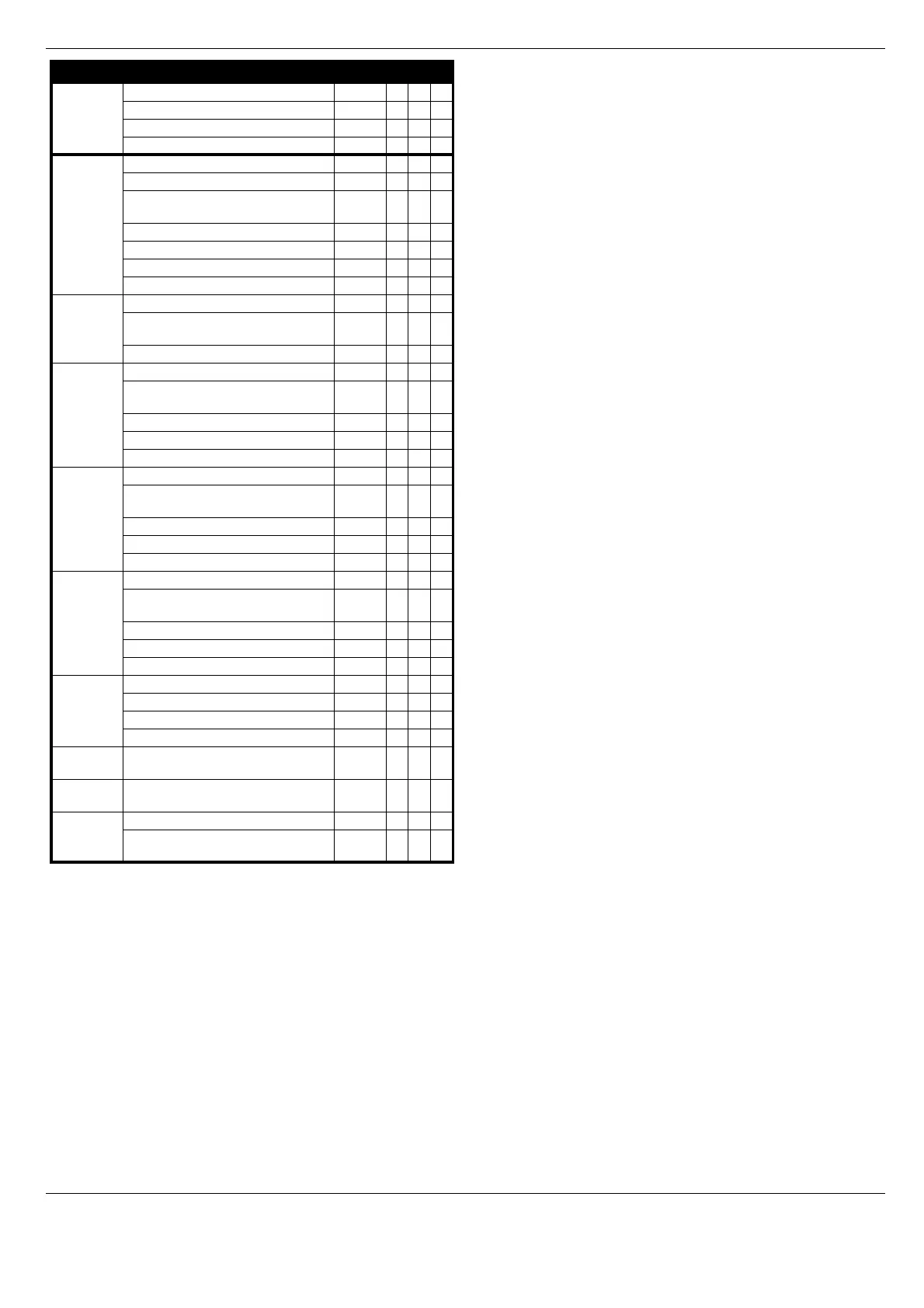

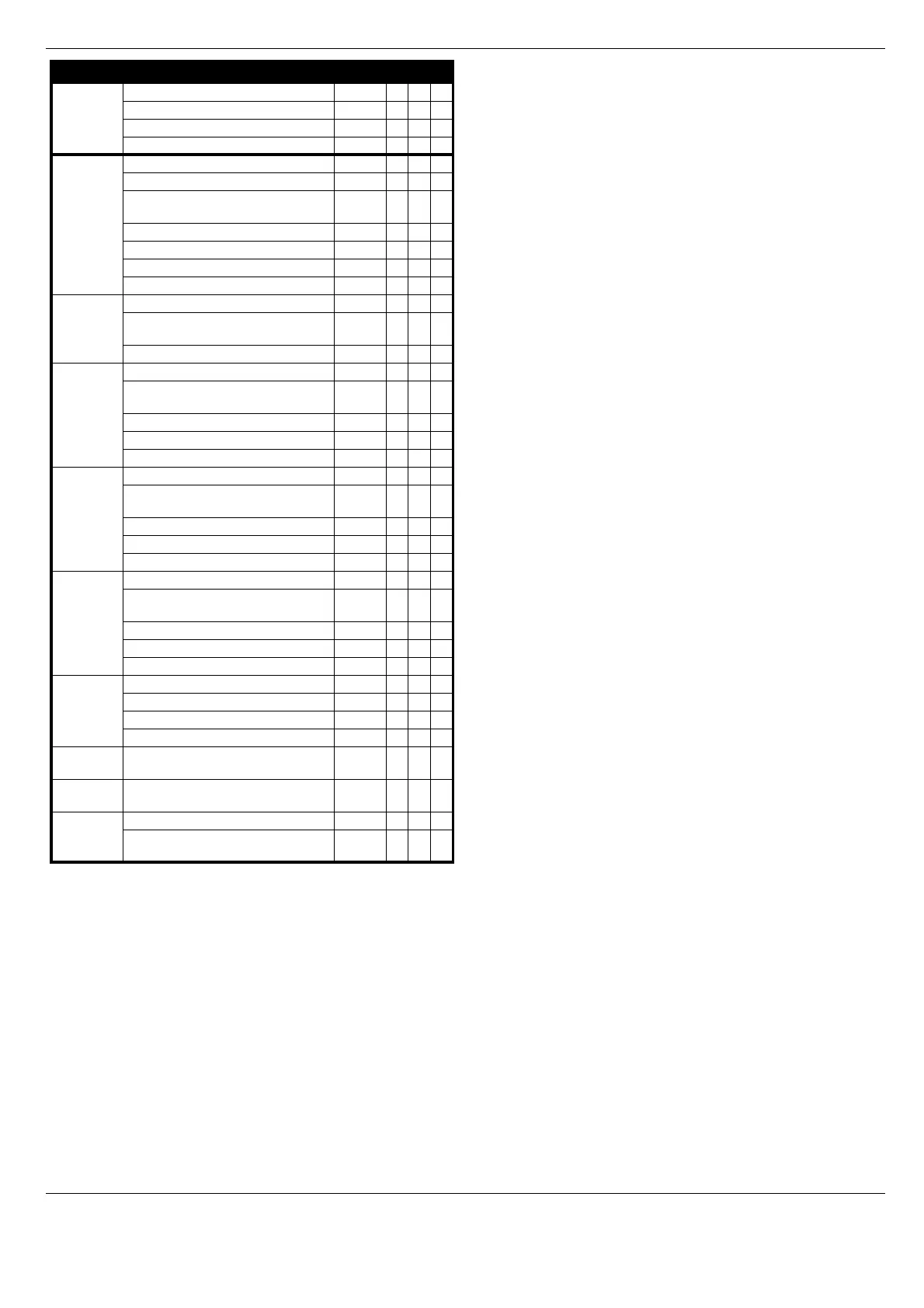

Service and Repair

3-3

Steering

System

Check hardware & fittings for proper torque 6m

Grease pivot pins 30d

Oil king pins 30d

Check steering cylinder for leaks 30d

Elevating

Assembly

Inspect for structural cracks Daily

Check pivot points for wear 30d

Check mounting pin pivot bolts for proper

torque

30d

Check linkage gear for wear. 6m

Check elevating arms for bending 6m

Grease linkage pins 30d

Grease linkage gear 30d

Chassis

Check hoses for pinch or rubbing points Daily

Check component mounting for proper

torque

6m

Check welds for cracks Daily

Lift Cylinder

Check the cylinder rod for wear 30d

Check mounting pin pivot bolts for proper

torque

30d

Check seals for leaks 30d

Inspect pivot points for wear 30d

Check fittings for proper torque 30d

Fore/Aft

Cylinder &

Side/Side

Cylinder

Check the cylinder rod for wear. 30d

Check mounting pin pivot bolts for proper

torque

30d

Check seals for leaks 30d

Inspect pivot points for wear. 30d

Check fittings for proper torque 30d

Axle Cylinder

Check the cylinder rod for wear. 30d

Check mounting pin pivot bolts for proper

torque

30d

Check seals for leaks 30d

Inspect pivot points for wear 30d

Check fittings for proper torque 30d

Entire Unit

Check for and repair collision damage Daily

Check fasteners for proper torque 3m

Check for corrosion-remove and repaint 6m

Lubricate 30d

Labels

Check for peeling, missing, or unreadable

labels & replace

Daily

Bubble Level

Check bubble level and target ring for

damage

Daily

Wheel

Bearings

Check wheel assembly for play 30d

Repack wheel bearings (replace wheel

bearings and seals at 2000 hours).

2y

COMPONENT INSPECTION OR SERVICES INTERVAL Y N R

Loading...

Loading...