47

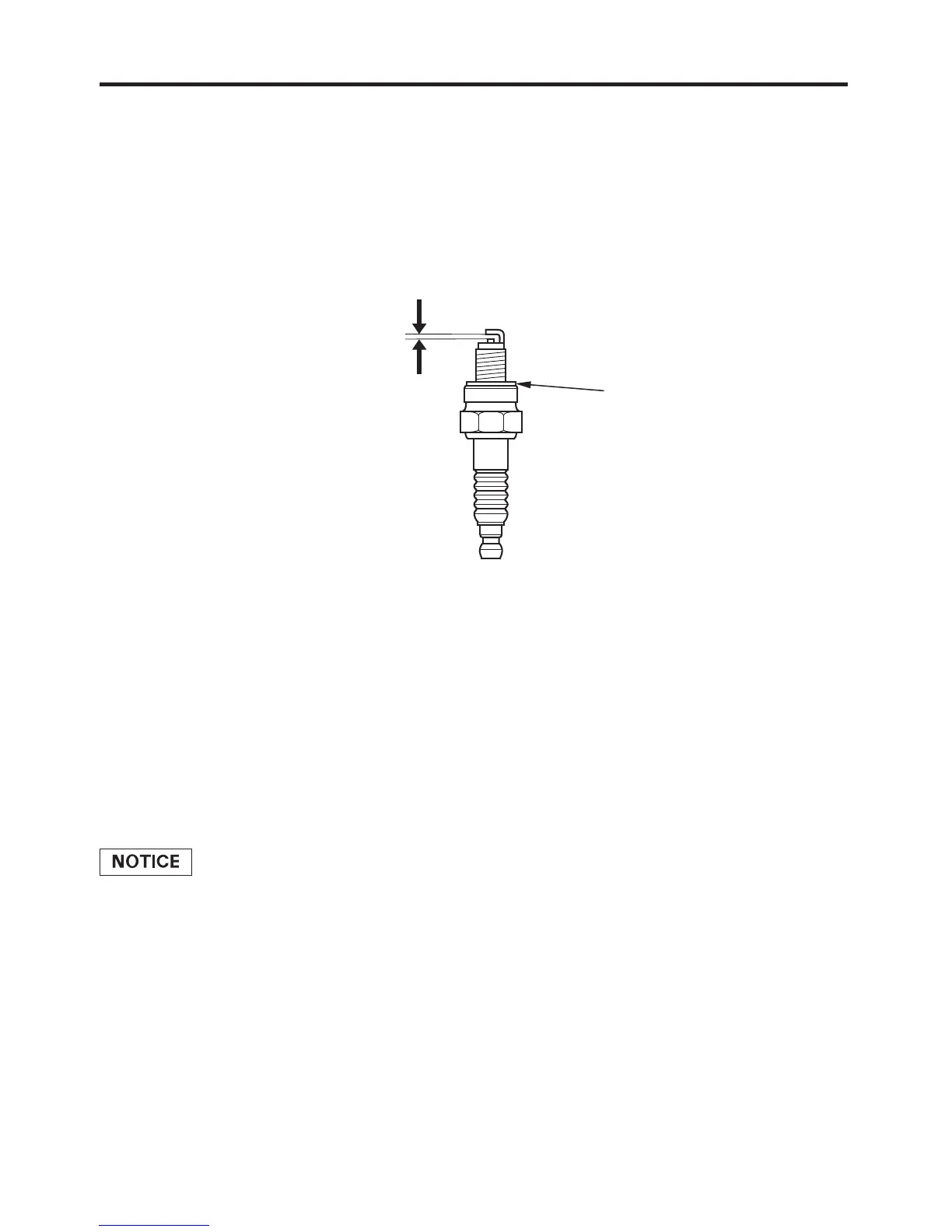

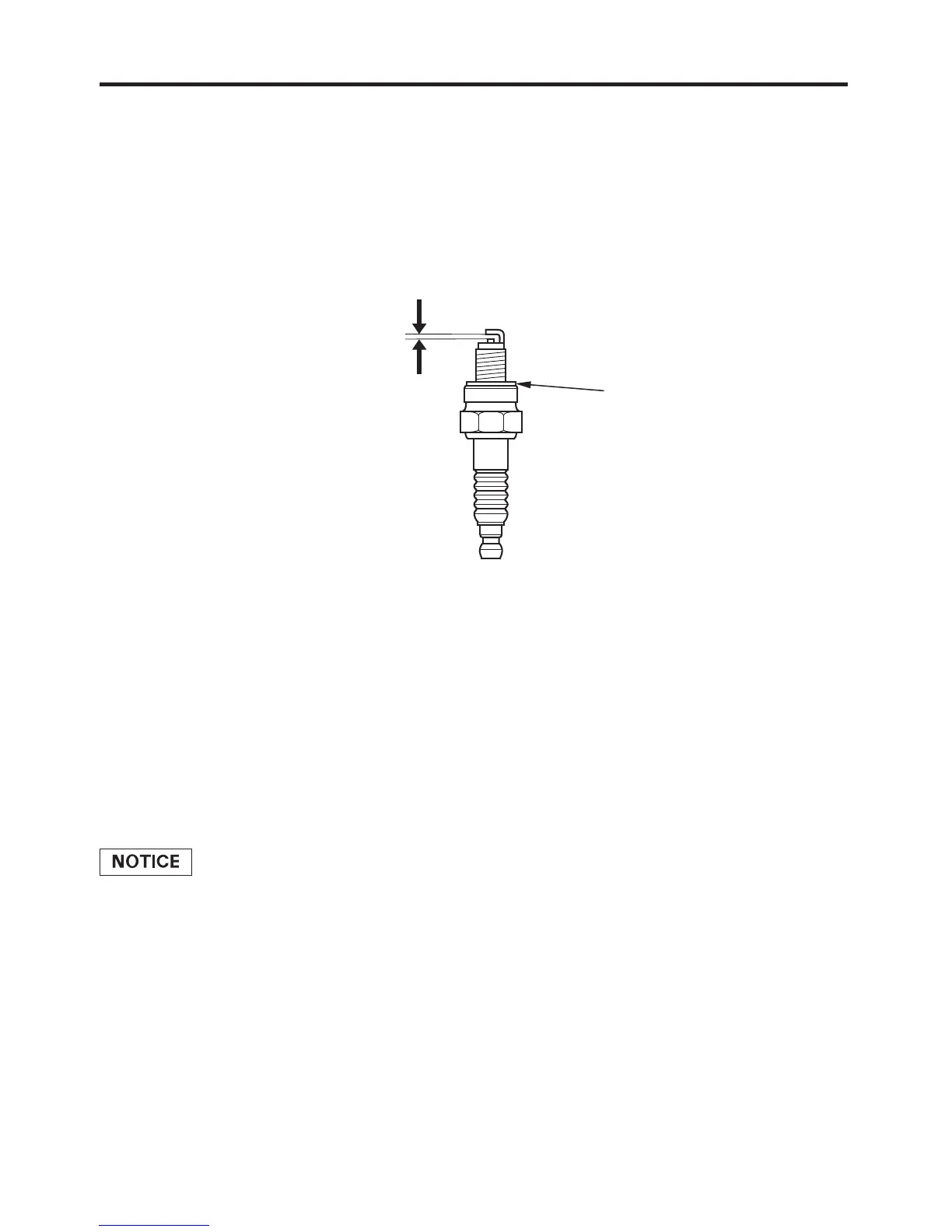

0.024 0.028 in

(0.60 0.70 mm)

SEALING WASHER

After the spark plug is seated, tighten with a spark plug wrench to

compress the washer.

If installing a new spark plug, tighten 1/2 turn after the spark plug

seats to compress the washer. If reinstalling a used spark plug,

tighten 1/8 1/4 turn after the spark plug seats to compress the

washer.

Measure the spark plug electr ode gap with a wire-type feeler gauge.

Correct the gap, if necessary, by carefully bending the side electrode.

Check that the spark plug sealing washer is in good condition, and

thread the spark plug in by hand to prevent cross-threading.

A loose spark plug can overheat and damage the engine.

Overtightening the spark plug can damage the threads in the cylinder

head.

Reinstall the spark plug cap on the spark plug securely.

Reinstall the spark plug maintenance cover.

0.024 0.028 in (0.60 0.70 mm)

Visually inspect the spark plug. Replace it if the electrodes are worn

or if the insulator is cracked, chipped, or fouled.

7.

8.

9.

5.

6.

10.

The gap should be:

_

_

_ _

_

Loading...

Loading...