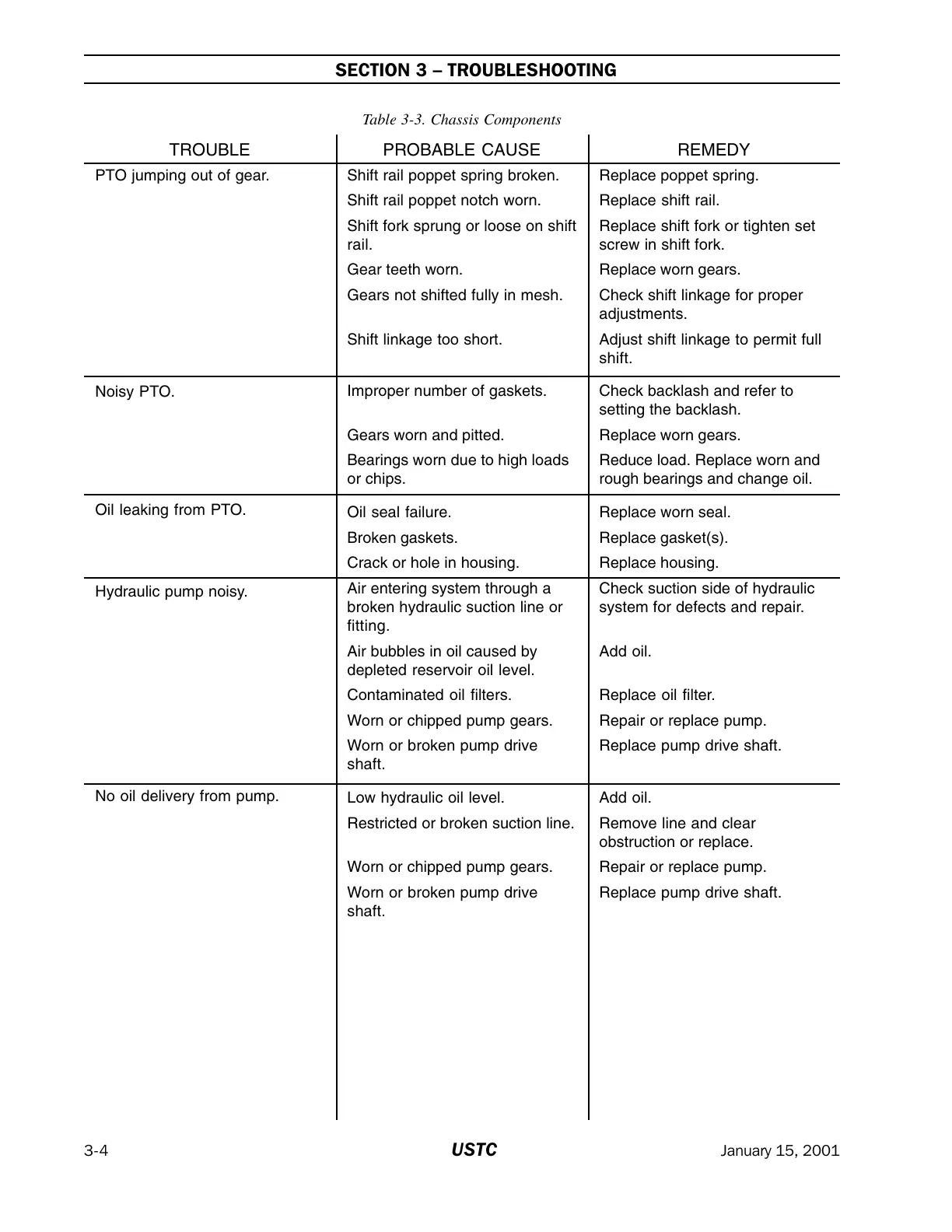

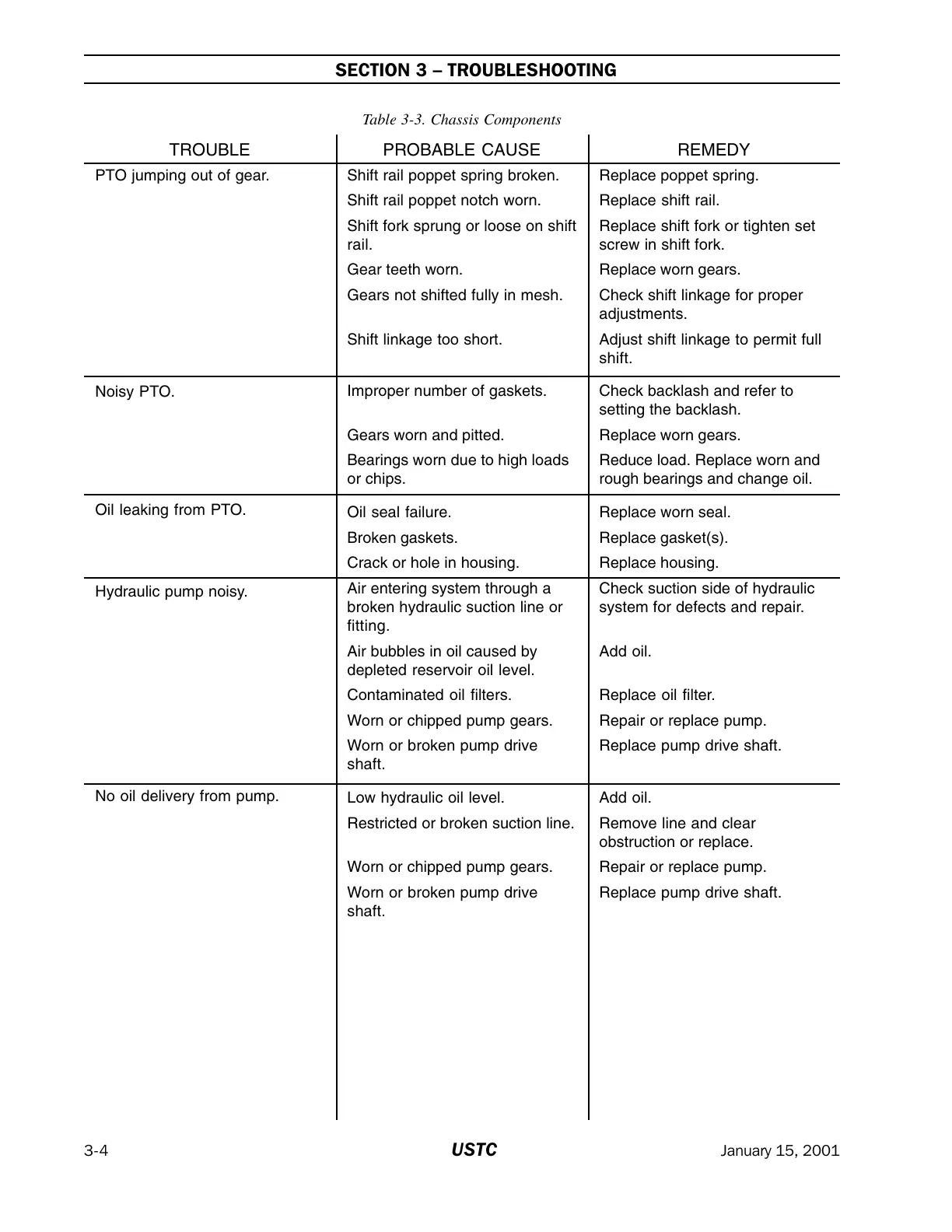

SECTION 3 – TROUBLESHOOTING

3-4 USTC January 15, 2001

TROUBLE PROBABLE CAUSE REMEDY

Table 3-3. Chassis Components

PTO jumping out of gear. Shift rail poppet spring broken.

Shift rail poppet notch worn.

Shift fork sprung or loose on shift

rail.

Gear teeth worn.

Gears not shifted fully in mesh.

Shift linkage too short.

Improper number of gaskets.

Gears worn and pitted.

Bearings worn due to high loads

or chips.

Oil seal failure.

Broken gaskets.

Crack or hole in housing.

Air entering system through a

broken hydraulic suction line or

fitting.

Air bubbles in oil caused by

depleted reservoir oil level.

Contaminated oil filters.

Worn or chipped pump gears.

Worn or broken pump drive

shaft.

Low hydraulic oil level.

Restricted or broken suction line.

Worn or chipped pump gears.

Worn or broken pump drive

shaft.

Replace poppet spring.

Replace shift rail.

Replace shift fork or tighten set

screw in shift fork.

Replace worn gears.

Check shift linkage for proper

adjustments.

Adjust shift linkage to permit full

shift.

Check backlash and refer to

setting the backlash.

Replace worn gears.

Reduce load. Replace worn and

rough bearings and change oil.

Replace worn seal.

Replace gasket(s).

Replace housing.

Check suction side of hydraulic

system for defects and repair.

Add oil.

Replace oil filter.

Repair or replace pump.

Replace pump drive shaft.

Add oil.

Remove line and clear

obstruction or replace.

Repair or replace pump.

Replace pump drive shaft.

Noisy PTO.

Oil leaking from PTO.

Hydraulic pump noisy.

No oil delivery from pump.

Courtesy of Crane.Market

Loading...

Loading...