SECTION 7 – HYDRAULICS

7-2 USTC January 15, 2001

Lift Cylinder

1. Activate hydraulic system and set outriggers

and stabilizers.

2. Position boom in horizontal position over rear

of truck.

Note: Tape measure or cord should be at least seven

(7) feet long for use in this test.

3. Attach tape measure or cord (at least 30 feet

long) to bottom of hook block.

WARNING: BEFORE RAISING AND

EXTENDING BOOM, ENSURE THAT AREAS

ABOVE AND BELOW BOOM AND HOOK

BLOCK ARE CLEAR OF ALL

OBSTRUCTIONS AND PERSONNEL.

4. Raise boom to a 15° elevation. Fully extend

boom.

5. Shut down hydraulic system by disengaging

Power-Take-Off (PTO) and turn off truck en-

gine.

6. With engine off, move boom control lever for-

ward.

If boom starts to lower, holding valve is defec-

tive and requires replacement.

If boom does not lower, complete steps 7

through 10.

CAUTION: HYDRAULIC LINES AND

PORTS SHOULD BE CAPPED IMMEDIATELY

AFTER DISCONNECTING LINES TO AVOID

ENTRY OF CONTAMINANTS INTO THE

SYSTEM.

7. Tag and carefully disconnect hydraulic lines to

lift cylinder. Use a suitable container to retain

any residual hydraulic fluid. Cap lines and

ports.

8. Note position of tape or cord and its position on

the ground. Mark as necessary. Leave boom

elevated in test position for approximately one

hour.

9. Check to see whether boom has lowered more

than eight inches.

If boom has lowered and oil is leaking around

rod-end cap of cylinder, seals in cylinder are

defective and require replacement.

If boom has lowered and oil is leaking from the

holding valve, the valve is either improperly

adjusted or defective and requires replacement.

CAUTION: ENSURE THAT HYDRAULIC

LINES ARE CONNECTED PROPERLY.

10. Connect hydraulic lines to lift cylinder.

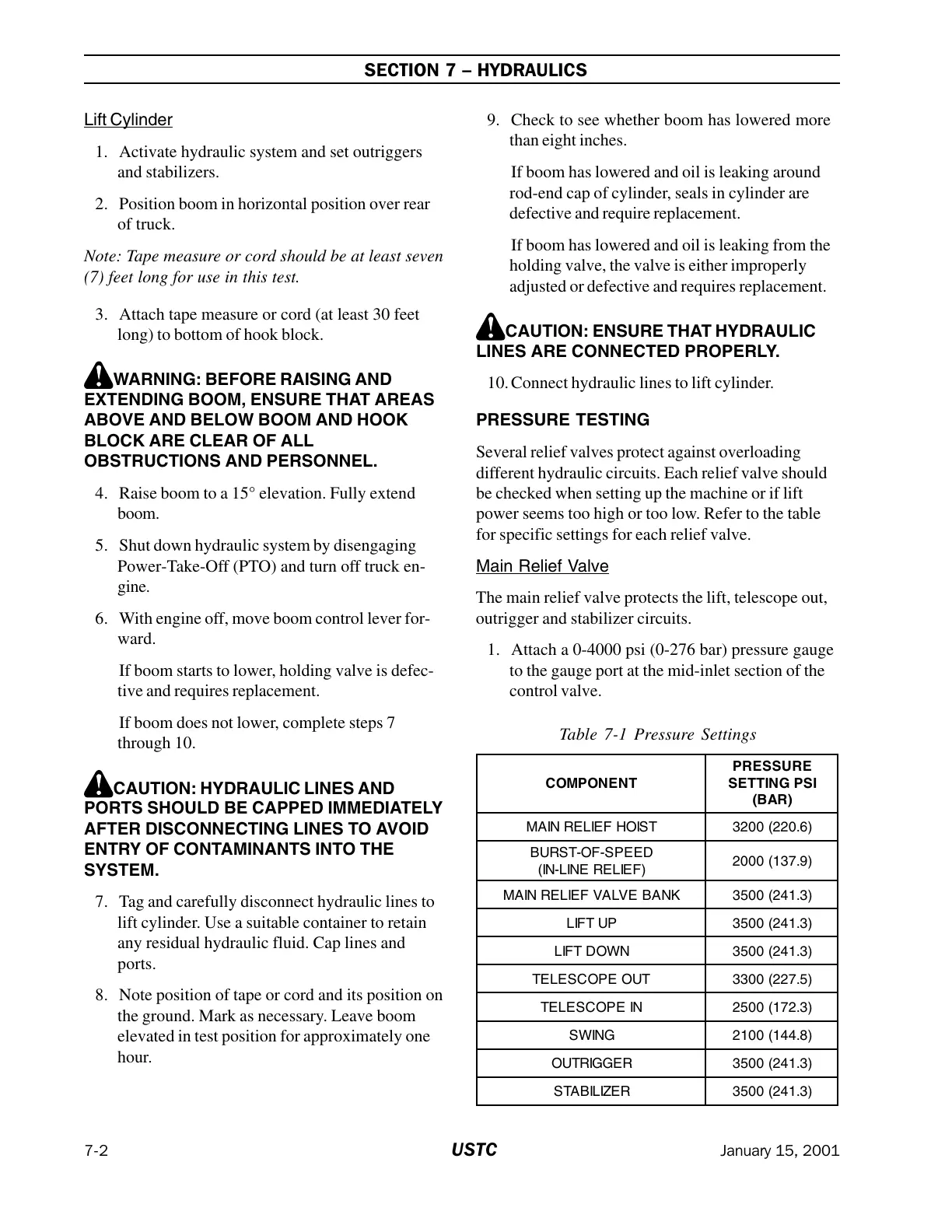

PRESSURE TESTING

Several relief valves protect against overloading

different hydraulic circuits. Each relief valve should

be checked when setting up the machine or if lift

power seems too high or too low. Refer to the table

for specific settings for each relief valve.

Main Relief Valve

The main relief valve protects the lift, telescope out,

outrigger and stabilizer circuits.

1. Attach a 0-4000 psi (0-276 bar) pressure gauge

to the gauge port at the mid-inlet section of the

control valve.

TNENOPMOC

ERUSSERP

ISPGNITTES

)RAB(

TSIOHFEILERNIAM)6.022(0023

DEEPS-FO-TSRUB

)FEILERENIL-NI(

)9.731(0002

KNABEVLAVFEILERNIAM)3.142(0053

PUTFIL)3.142(0053

NWODTFIL)3.142(0053

TUOEPOCSELET)5.722(0033

NIEPOCSELET)3.271(0052

GNIWS)8.441(0012

REGGIRTUO)3.142(0053

REZILIBATS)3.142(0053

Table 7-1 Pressure Settings

Courtesy of Crane.Market

Loading...

Loading...