Vacon Plc Phone: +358-201 2121 Fax:+358-201 212 205

Service: +358-40-8371 150 E-mail: vacon@vacon.com

Page 28 Vacon

Pump and fan control with autochange

scale.

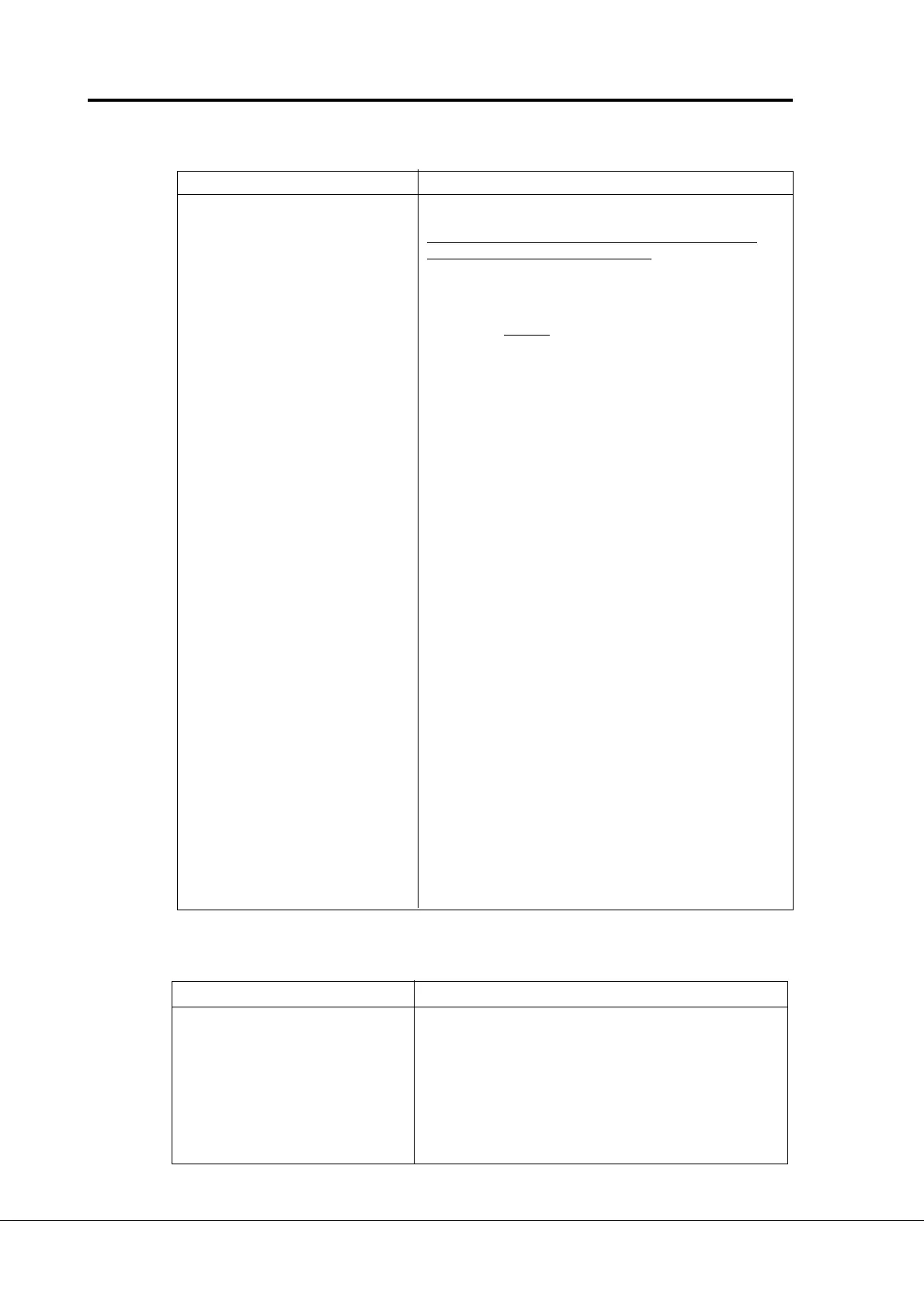

3. 6 Digital output function

Setting value Signal content

0 = Not used Out of operation

Digital output DO1 sinks current and programmable

relay (RO1, RO2) is activated when:

1 = Ready The frequency converter is ready to operate

2 = Run The frequency converter operates (motor is running)

3 = Fault A fault trip has occurred

4 = Fault inverted A fault trip

has not occurred

5 = Vacon overheat warning The heat-sink temperature exceeds +70°C

6 = External fault or warning Fault or warning depending on parameter 7. 2

7 = Reference fault or warning Fault or warning depending on parameter 7. 1

- if analogue reference is 4—20 mA and signal is <4mA

8 = Warning Always if a warning exists

9 = Reversed The reverse command has been selected

10= Multi-step or jogging speed Multi-step or jog. speed has been selected with digital

input

11 = At speed The output frequency has reached the set reference

12= Motor regulator activated Overvoltage or overcurrent regulator was activated

13= Output frequency supervision 1 The output frequency goes beyond the set supervision

Low limit/ High limit (par. 3. 9 and par. 3. 10)

14= Output frequency supervision 2 The output frequency goes beyond the set supervision

Low limit/ High limit (par. 3. 11 and par. 3. 12)

15= Torque limit supervision The motor torque goes beyond the set supervision

Low limit/ High limit (par. 3. 13 and par. 3. 14)

16= Active reference Active reference goes beyond the set supervision

limit supervision Low limit/ High limit (par. 3. 15 and par. 3. 16)

17= External brake control External brake ON/OFF control with programmable de

lay (par 3. 17 and 3. 18)

18= Control from I/O terminals External control mode selected with pr. push-button #2

19= Frequency converter Temperature on frequency converter goes beyond

temperature limit supervision set supervision limits (par. 3. 19 and 3. 20)

20= Unrequested rotation direction Rotation direction of the motor shaft is different from the

requested one

21 = External brake control inverted External brake ON/OFF control (par. 3.17 and 3.18),

output active when brake control is ON

22= Analog input limit supervision The level of selected analog input goes beyond the

set supervision low / high limit (par. 3. 29 and par. 3. 30)

23—26 = Not in use

27 = Autochange 3 control Control signal for drive 3 in autochange system

28 = Auxiliary drive 1 start Starts and stops auxiliary drive 1

29 = Auxiliary drive 2 start Starts and stops auxiliary drive 2

30 = Auxiliary drive 3 start Starts and stops auxiliary drive 3

Table 6-3a Output signals via DO1

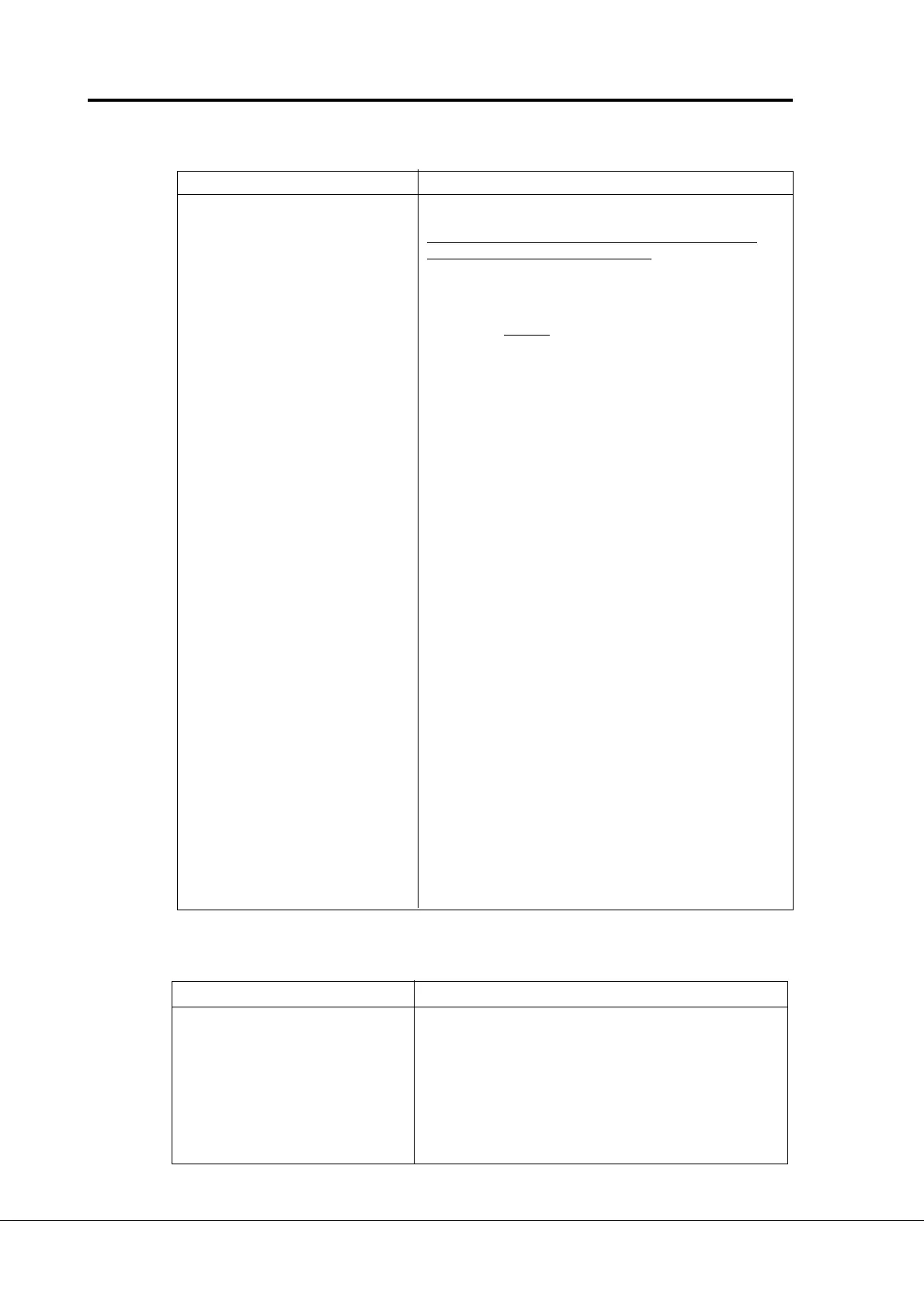

3. 7 Relay output 1 content

Setting value Signal content

0-22 = Same as parameter 3.6

23—25 = Not in use

26 = Autochange 1 control Control signal for drive 1 in autochange system

27 = Autochange 4 control Control signal for drive 1 in autochange system with

I/O-expander option

28 = Auxiliary drive 1 start Starts and stops auxiliary drive 1

29 = Auxiliary drive 2 start Starts and stops auxiliary drive 2

30 = Auxiliary drive 3 start Starts and stops auxiliary drive 3

Table 6-3b Output signals via RO1

Loading...

Loading...