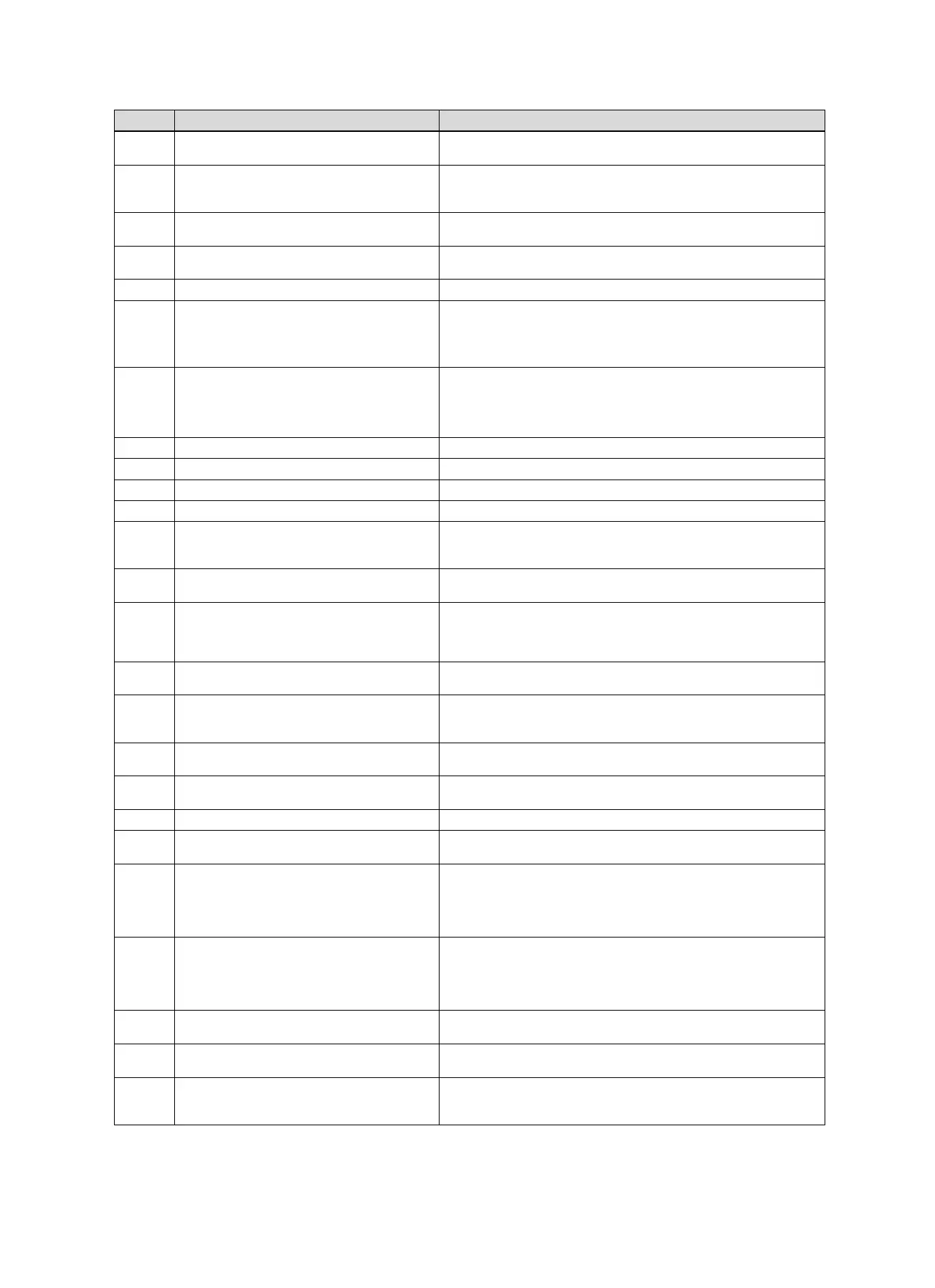

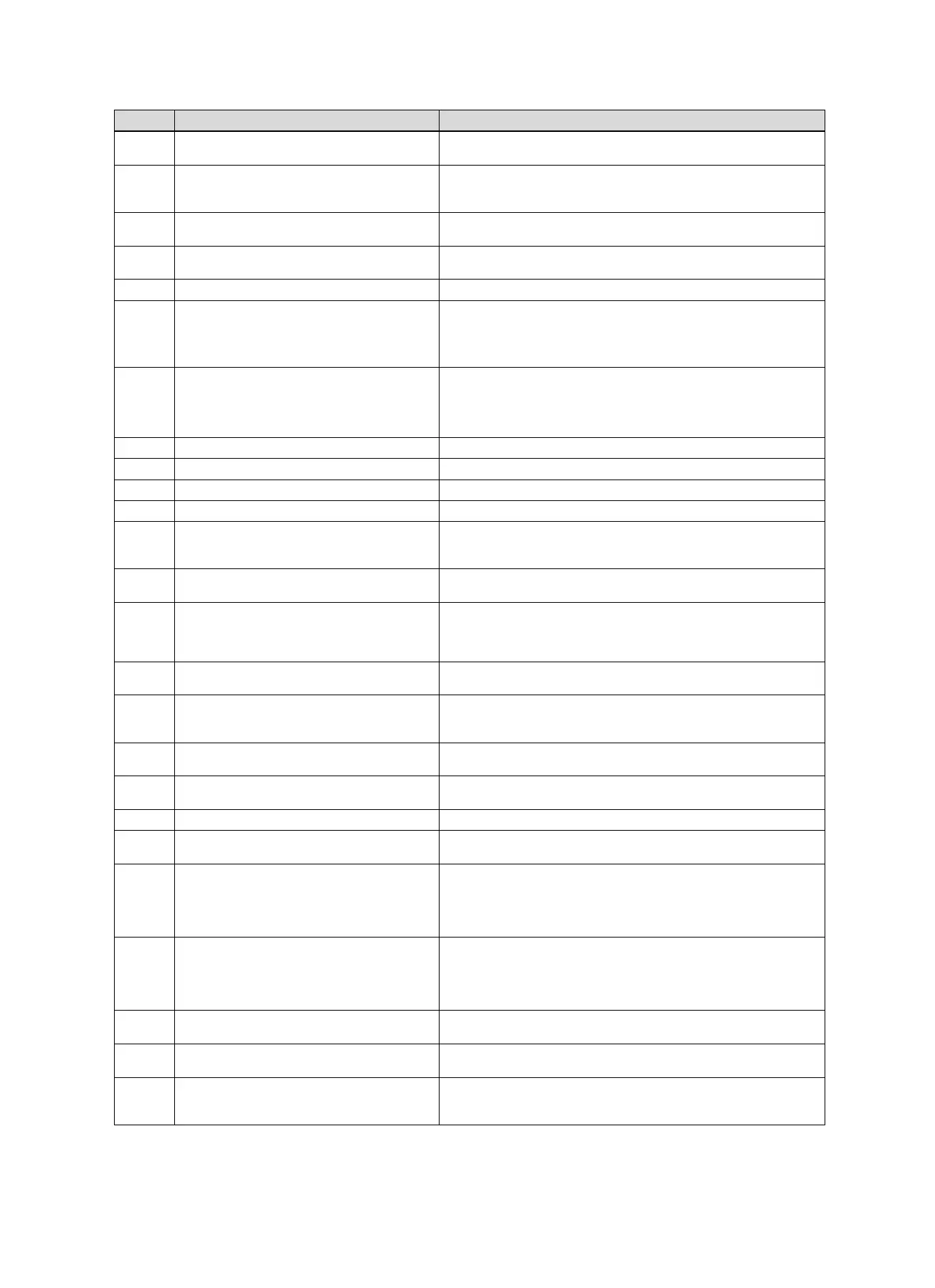

Appendix

52 Installation and maintenance instructions ecoCOMPACT 0020181421_04

Code Meaning Cause

F.52 Mass flow sensor connection fault Mass flow sensor not connected/disconnected, plug not connected or

incorrectly connected

F.53 Mass flow sensor fault Gas flow pressure too low, filter under Venturi filter cap wet or blocked,

mass flow sensor defective, internal pressure measuring point in Venturi

blocked (do not use lubricant on Venturi O-ring.)

F.54 Gas pressure fault (in combination with

F.28/F.29)

No or insufficient gas inlet pressure, gas stopcock closed

F.56 Fault: Mass flow sensor control Gas valve assembly defective, cable harness to gas valve assembly

defective

F.57 Fault during comfort protection mode Ignition electrode highly corroded

F.61 Gas valve assembly control system fault – Short circuit/short to earth in cable harness for the gas valve as-

sembly

– Gas valve assembly defective (coils shorted to earth)

– Electronics defective

F.62 Gas valve assembly fault, switch-off delay – Delayed shutdown of gas valve assembly

– Delayed extinguishing of flame signal

– Gas valve assembly leaking

– Electronics defective

F.63 Fault: EEPROM Electronics defective

F.64 Fault: Electronics/NTC Flow or return NTC short circuited, electronics defective

F.65 Fault: Electronics temp. Electronics overheating due to external influences, electronics defective

F.67 Fault: Electronics/flame Implausible flame signal, electronics defective

F.68 Fault: Unstable flame signal Air in gas, gas flow pressure too low, incorrect air ratio, condensate

route blocked, incorrect burner jet, ionisation flow interruption (cable,

electrode), flue gas recirculation, condensate route, electronics defective

F.70 Invalid device specific number (DSN) If spare parts fitted: Display and PCB replaced at same time and DSN

not reset, incorrect or missing output range coding resistor

F.71 Flow temperature sensor fault Flow temperature sensor signalling constant value:

– Flow temperature sensor incorrectly positioned on the flow pipe

– Flow temperature sensor defective

F.72 Flow and/or return temperature sensor fault Flow/return NTC temperature difference too great → flow and/or return

temperature sensor defective

F.73 Water pressure sensor signal in the wrong range

(too low)

Interruption/short circuit of water pressure sensor, interruption/short

circuit to GND in supply line to water pressure sensor or water pressure

sensor defective

F.74 Water pressure sensor signal outside correct

range (too high)

Line to water pressure sensor has a short circuit to 5 V/24 V or internal

fault in the water pressure sensor

F.75 Fault: Insufficient throughput on pump start-up. Pump defective, air in heating installation, too little water in unit, mass

flow sensor defective

F.77 Fault: Flue non-return flap/condensate pump No response from flue non-return flap or condensate pump defective

F.82 External current anode fault (if installed as an

accessory)

Anode connection or external current anode PCB defective

F.83 Fault: Flow and/or return temperature sensor

temperature change

When the burner starts, the temperature change registered at the flow

and/or return temperature sensor is non-existent or too small

– Insufficient water in product

– Flow or return temperature sensor not in correct position at pipe

F.84 Fault: Flow/return temperature sensor temperat-

ure difference implausible

Flow and return temperature sensors returning implausible values.

– Flow and return temperature sensors have been inverted

– Flow and return temperature sensors have not been correctly in-

stalled

F.85 Fault: Flow and return temperature sensors

incorrectly installed

The flow and/or return temperature sensors have been installed on the

same pipe/incorrect pipe

F.86 Fault: Floor contact Safety thermostat when underfloor heating is switched on: Setting the

target heating value

F.92 Fault in the gas coding resistor The coding resistor on the PCB does not match the entered gas group:

Check the resistance, repeat the gas family check and enter the correct

gas group.

Loading...

Loading...