36 Installation and maintenance instructions ecoFIT pure 0020230533_06

– Clearance for the ignition electrodes: 3.5 to 4.5 mm

6. Make sure that the seal (5) is free from damage.

▽ If necessary, replace the seal.

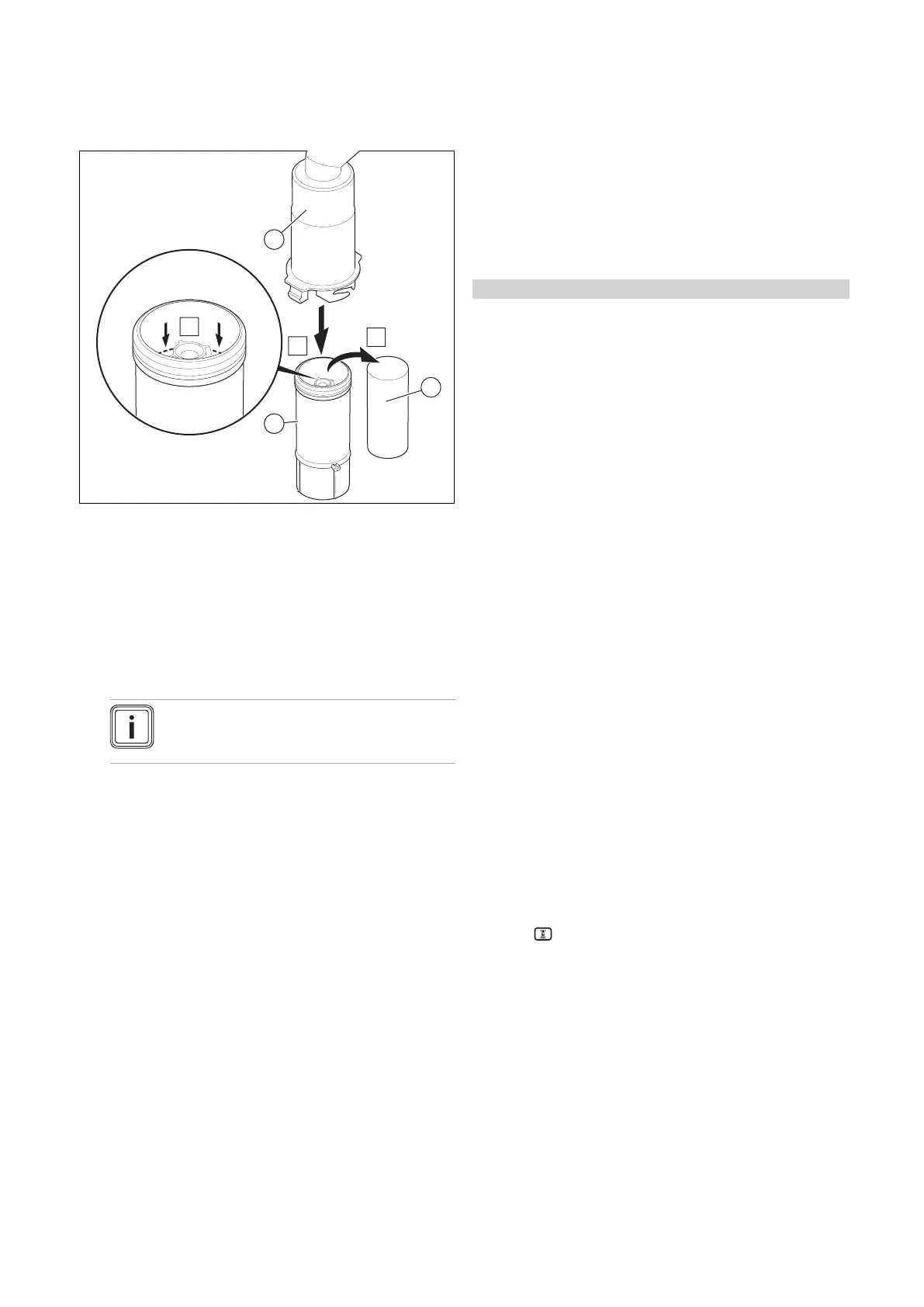

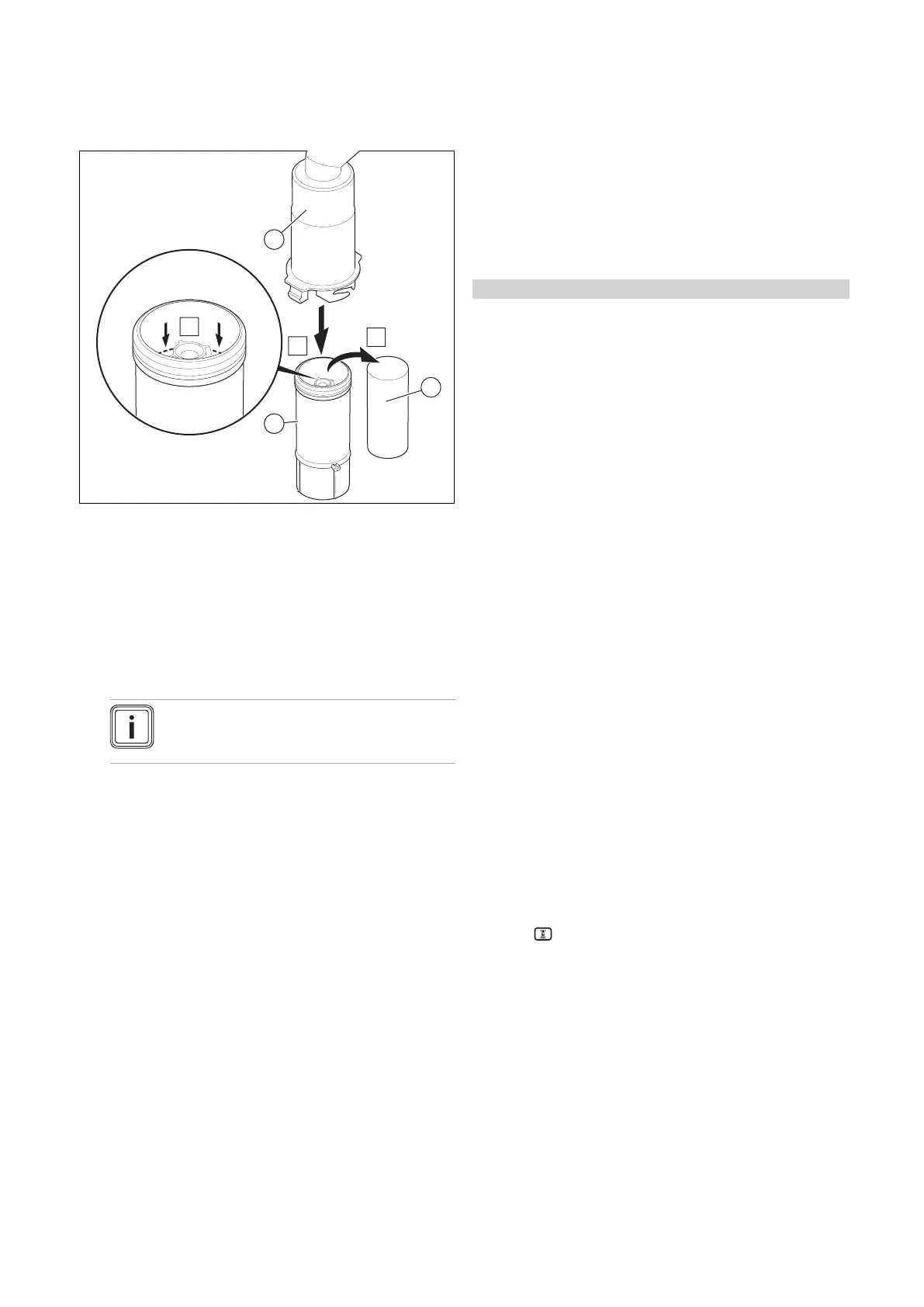

12.10 Cleaning the condensate trap

1. Unclip the lower section of the condensate trap (1) from

the upper section of the condensate trap (2).

2. Remove the float (3).

3. Flush out the float and lower section of the condensate

trap with water.

4. Fill the lower section of the condensate trap with water

up to 10 mm below the upper edge of the condensate

discharge pipe.

5. Re-insert the float (3).

Note

Check whether the float is present in the

condensate trap.

6. Clip the lower section of the condensate trap (1) into the

upper section of the condensate trap (2).

12.11 Installing the gas-air mixture unit

1. Install the burner.

2. Install two new burner seals in the burner hood.

3. Install the gas-air mixture unit.

4. Tighten the screws in a cross-wise pattern until the

burner flange fits closely and uniformly onto the mat-

ing surfaces.

– Tightening torque: 7 Nm, if a torque spanner is

available

5. Install the flue pipe.

6. Install the air intake pipe.

12.12 Draining the product

1. Close the service valves of the product.

2. Start check programme P.05.

Overview of the check programmes (→ Page 26)

3. Open the drain valves.

12.13 Checking the pre-charge pressure of the

expansion vessel

1. Drain the product. (→ Page 36)

2. Measure the pre-charge pressure of the expansion ves-

sel at the vessel valve.

Condition: Pre-charge pressure < 0.075 MPa (0.75 bar)

▶ Top up the expansion vessel in accordance with the

static height of the heating installation, ideally with ni-

trogen, otherwise with air. Ensure that the drain valve is

open when topping up.

3. If water escapes from the valve of the expansion

vessel, you must replace the expansion vessel

(→ Page 38).

4. Fill and purge the heating installation. (→ Page 28)

12.14 Completing inspection and maintenance

work

1. Check the gas connection pressure (gas flow pressure).

(→ Page 29)

2. Check the CO₂ content. (→ Page 30)

3. Set the maintenance interval.

4. Check the product for tightness. (→ Page 31)

5. Install the front casing. (→ Page 18)

6. Fill out the relevant Service Record section in the

Benchmark Checklist located at the rear of this

document.

13 Troubleshooting

13.1 Eliminating faults

▶ If fault messages (F.xx) appear, eliminate the fault after

referring to the table in the appendix or using the check

programmes. (→ Page 26)

Overview of fault codes (→ Page 46)

If several faults occur at the same time, the display shows

the corresponding fault messages for two seconds each in

alternation.

▶ Press (max. three times) to restart the product.

▶ If you are unable to eliminate the fault and the fault re-

curs despite reset attempts, contact customer service.

Loading...

Loading...