Appendix

0020265768_01 eloBLOCK Installation and maintenance instructions 27

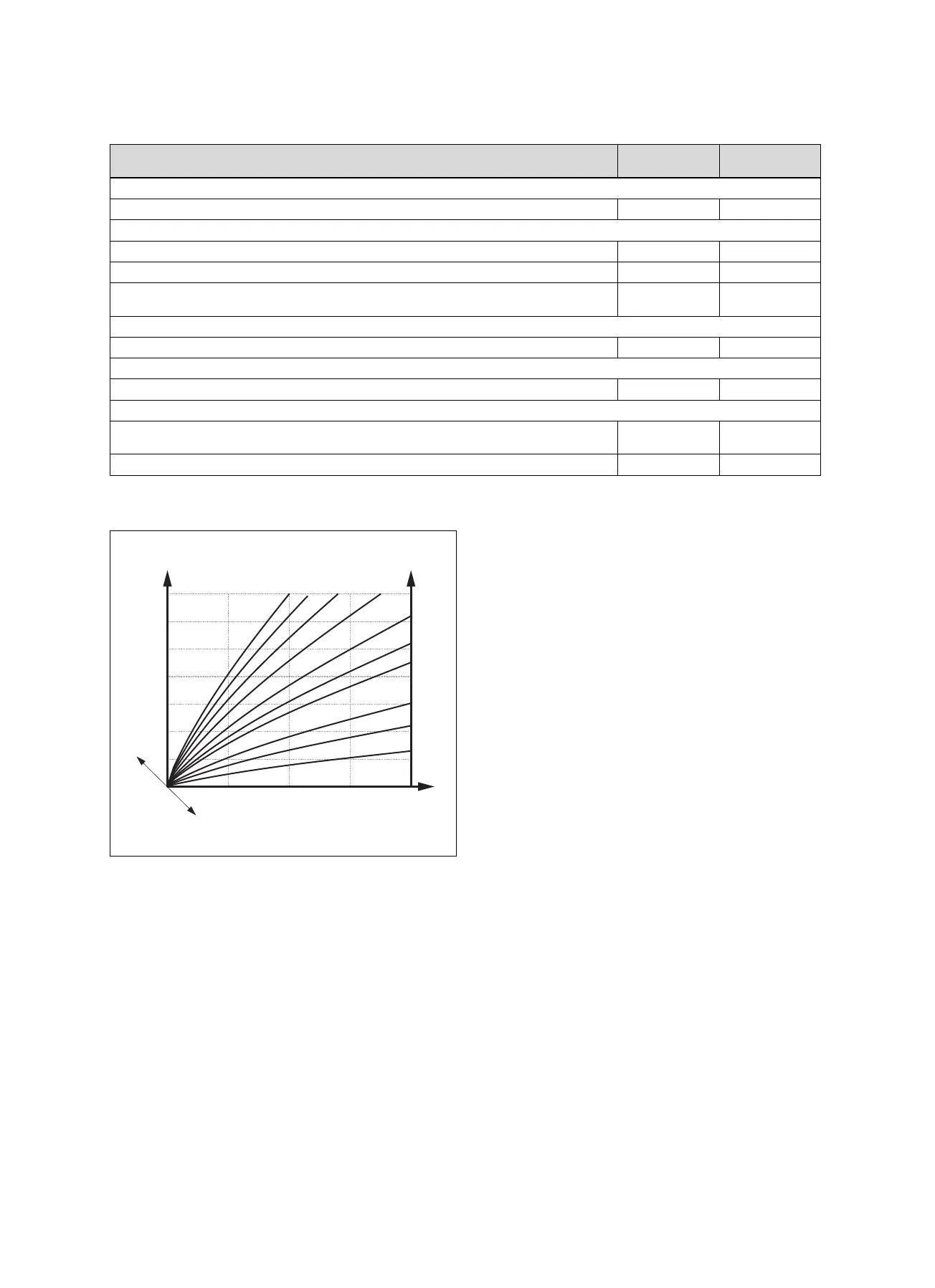

G Inspection and maintenance work – Overview

Work To be carried

out in general

To be carried

out as required

Function check

Check that the product is functioning correctly and check the technical parameters.

X

Checking the hydraulics

Check the filling pressure of the heating installation and top up with water, if necessary.

X X

Check the pre-charge pressure of the expansion vessel and increase the pressure, if necessary.

X

Check the purging valve, the expansion relief valve, the 3-way diverter valve, the heat exchanger

and all of the hydraulic components.

X

Safety test

Check all of the sensors, thermostats and safety components.

X

Checking the construction

Check that all of the screws and connections are seated firmly.

X

Checking the electrical installation

Check the electrical components, the wiring and the connection cable. Tighten the screw termin-

als, if necessary.

X

Rectify any faults discovered. X

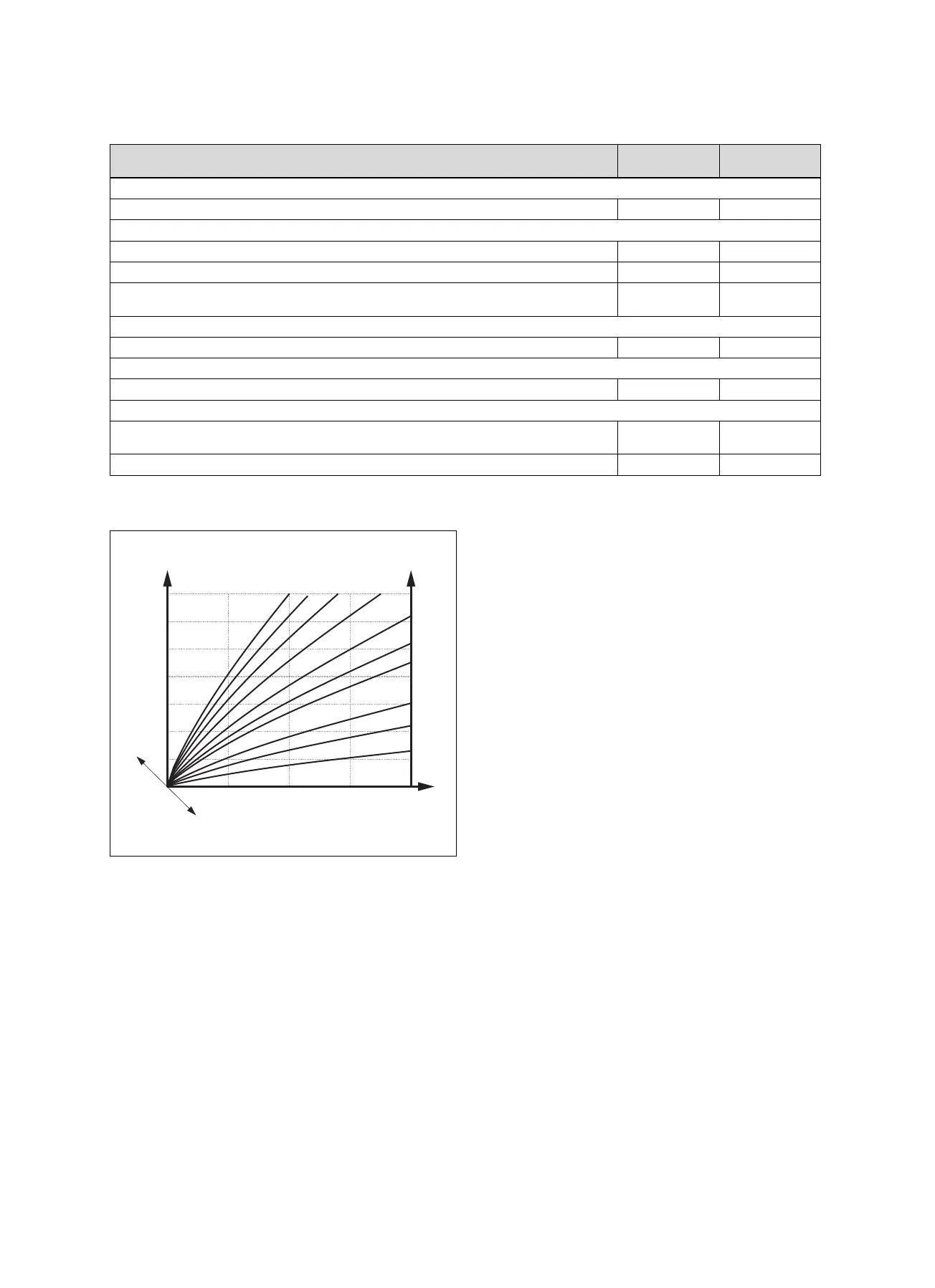

H Heat curves

20

15

25

30

40

50

60

70

80

90

-20-10010

0,2

0,4

0,6

1

1,2

1,5

22,533,5

AB

C

D

A: Flow temperature in °C

B: Heat curves

C: Outdoor temperature in °C

D: Target room temperature

Loading...

Loading...