512

Thermo E+ 120/200/320 5 Troubleshooting

5.6.4 Resistance check of the temperature

sensor with integrated overheating

protection

Observe the risk of injuries due to increased coolant

temperature.

Prior to removing the temperature sensor, the over-

pressure in the cooling system must be released (e.g.

by opening the cooler lid). Possibly let the heater

before cool down and have collecting container ready

for discharged coolant.

Inspection

• Inspect temperature sensor, plug and cable for

damage and proper fit.

• Remove temperature sensor (see 8.3).

• Perform the electrical test using a measuring device

suitable for resistance measurements.

• The water temperature sensor and the overheating

protection should indicate values according to the

charts (Fig.503 and Fig.504). Preferably the resis-

tance should be measured at an approx. consistent

temperature of 20°C and approx. 100°C (immerse

sensor up to the copper gasket ring into boiling water).

Prior to reading the value, the sensor should be expo-

sed to the temperature for approx. 20 seconds. A

measurement tolerance of +/- 5°C under workshop

conditions is permitted.

• Install temperature sensor (see 8.3).

Resistance vs. temperature charts

Fig.502

Pin 1 & 3

Pin 2 & 3

Overheat protection

Water

temperature sensor

(PT2000)

(PT500)

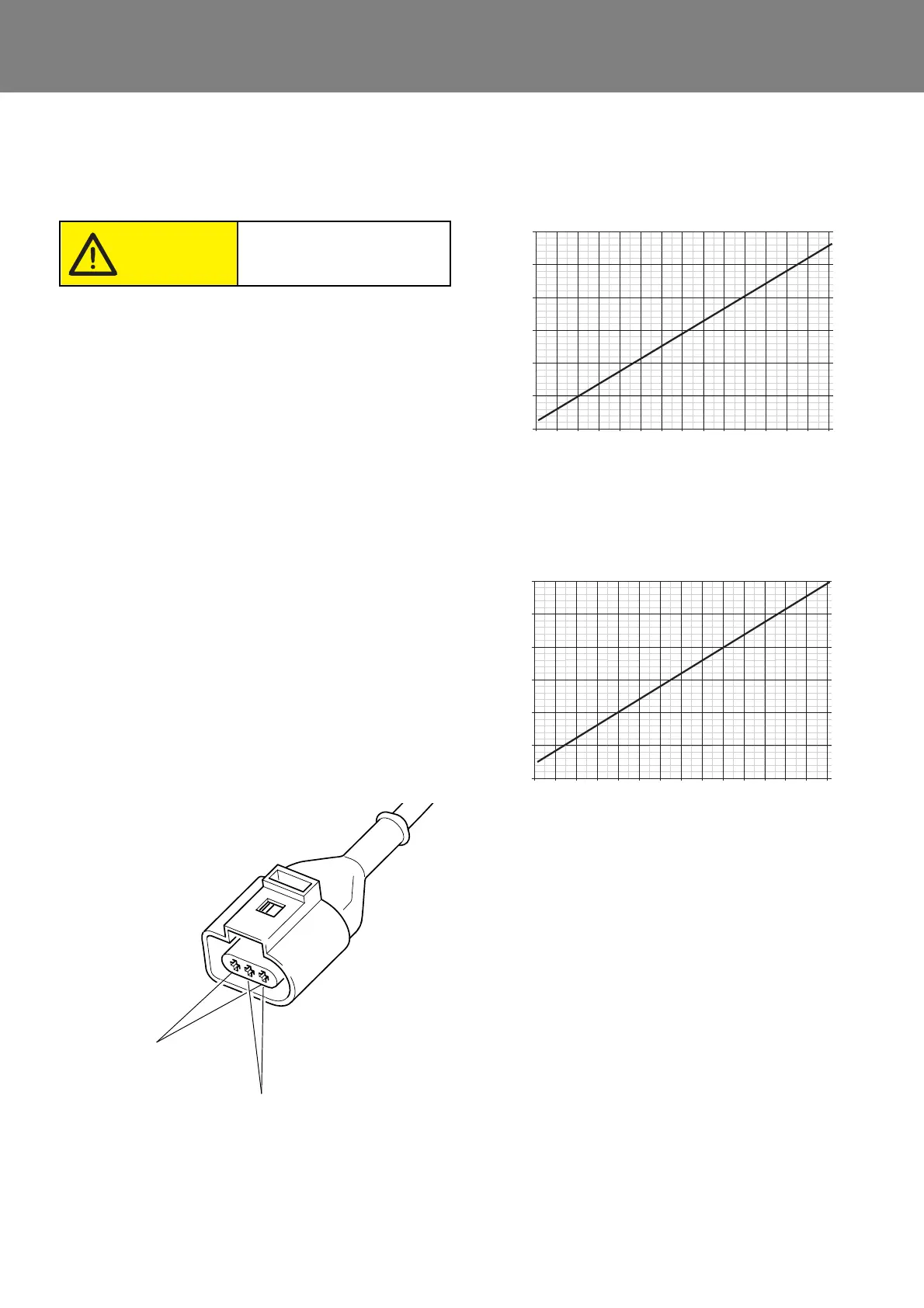

Fig.503

Fig.504

Water temperature sensor (Pin 1 and 3)

Resistance in Ohm

Temperature in °C

-40 -30 -20 -10 0 10 20 30 40 50 60 70 80 90 100

2850

2650

2450

2250

2050

1850

1650

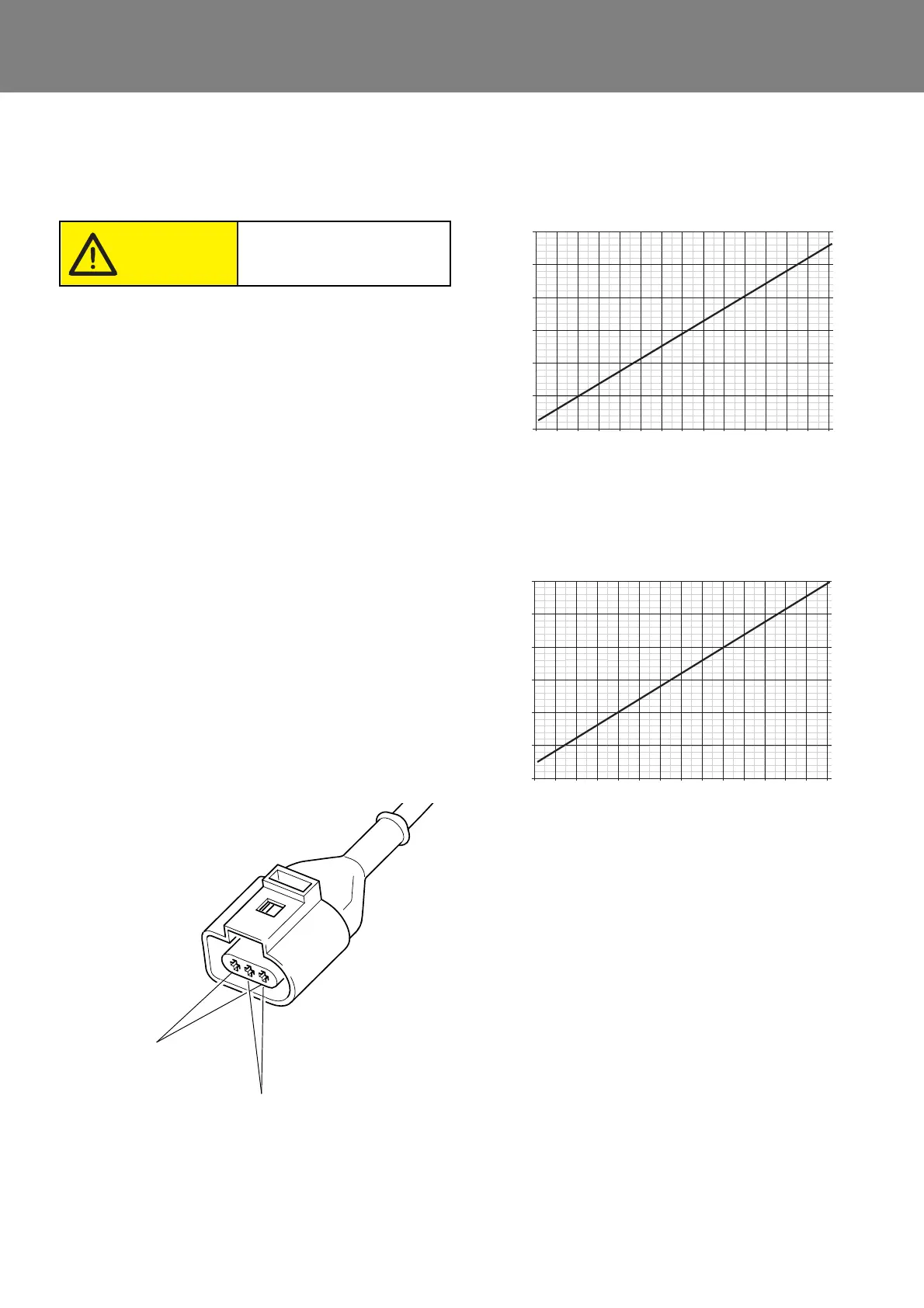

Overheating protection (Pin 2 and 3)

Resistance in Ohm

Temperature in °C

-40 -30 -20 -10 0 10 20 30 40 50 60 70 80 90 100

700

650

600

550

500

450

400

Loading...

Loading...