BCs160VA

Nov. 15, 1997

SMART-PULP Smart Consistency Transmitter

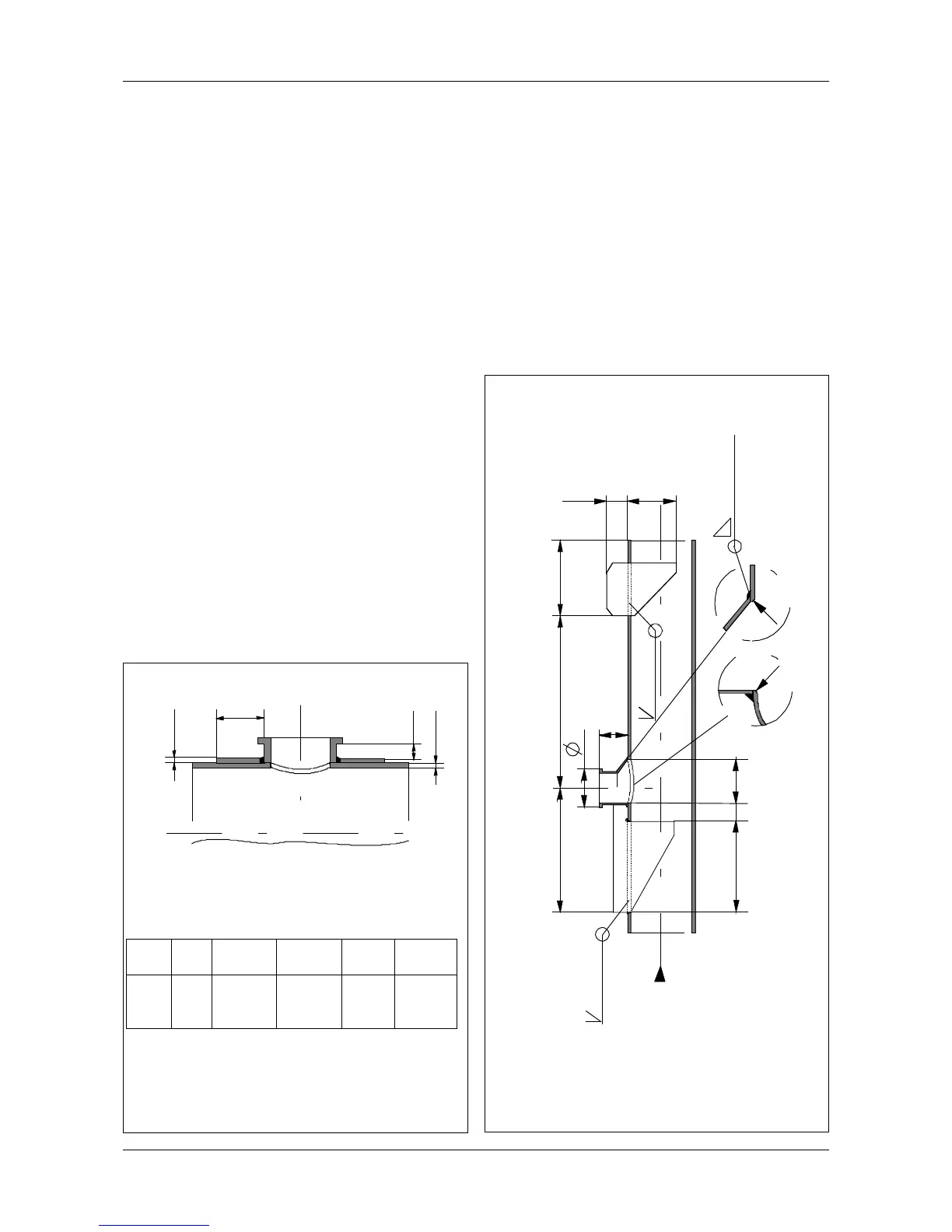

SMART-PULP HL in digester blow

line installations

Install the blow line coupling with single bevel weld

at right angles against the pipe, as shown in Figure

1.1.3d. See that the deflector is exactly in line with

the pipe’s center line. The coupling’s lower edge

should be level with the pipe’s inner wall.

Regulations concerning pressurized vessel

installations must be observed when welding the

coupling.

SMART-PULP JL

Installation of the process coupling on fiberglass-

reinforced plastic pipe is illustrated in Figure 1.1.3e.

First make a bevelled hole in the pipe. Then

laminate the process coupling carefully on the pipe

in accordance with lamination instructions.

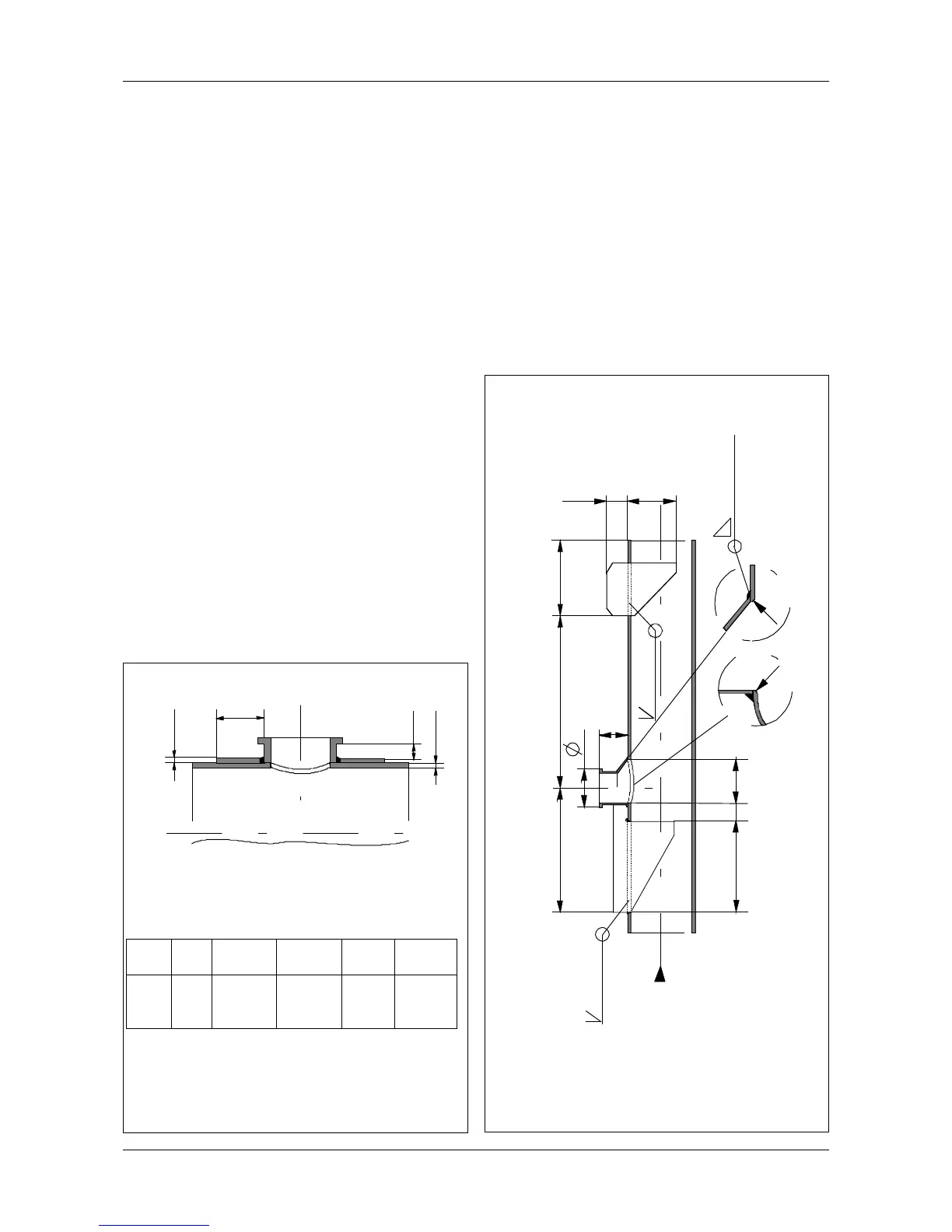

Figure 1.1.3c Installation for SMART-PULP WS

Figure 1.1.3b Reinforcing the process coupling

7

D = pipes inside diameter

s = pipes wall thickness

Io = width of reinforcing ring

h = thickness of reinforcing ring

NOTE! If the pipes wall thickness is greater than

that given in the table, the thickness of the

reinforcing ring can be correspondingly smaller.

60

95

120

420

*)

54

R

R

90

11 5

85

180

303

**)

FLOW

*) Plate thickness 4 mm

**) Plate thickness 8 mm

Weld

4 Weld

Weld

h

Io

min.

6 mm

s

D

mm

250

400

500

s

mm

4

6

7

p max.

bar

25

25

25

T max.

o

C

100

100

100

Io

mm

32

50

60

h

mm

5

5

6

Loading...

Loading...