1237

Model Code Page

90. Hydraulic system

1. 1. 1995

6000--8750 910 25

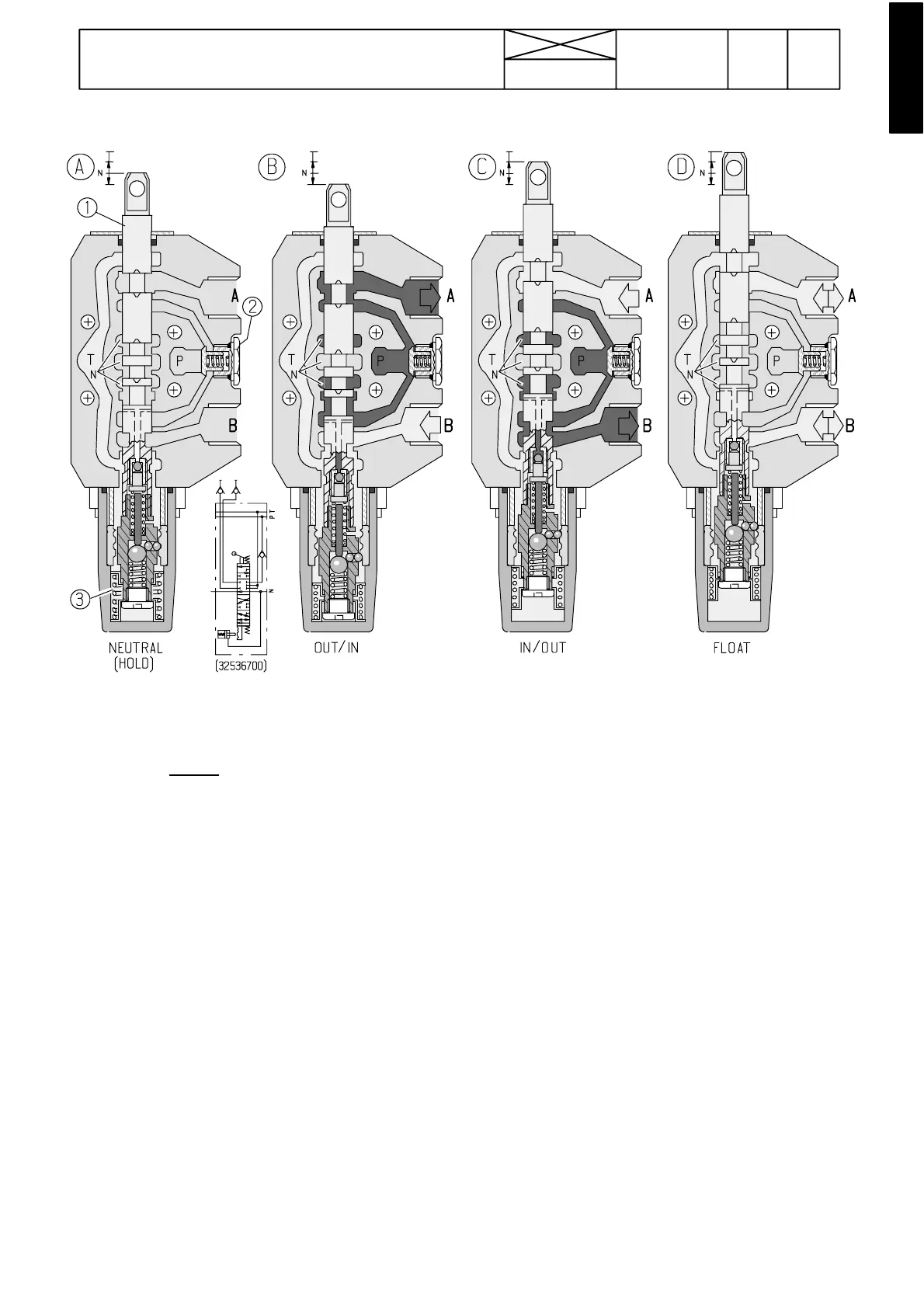

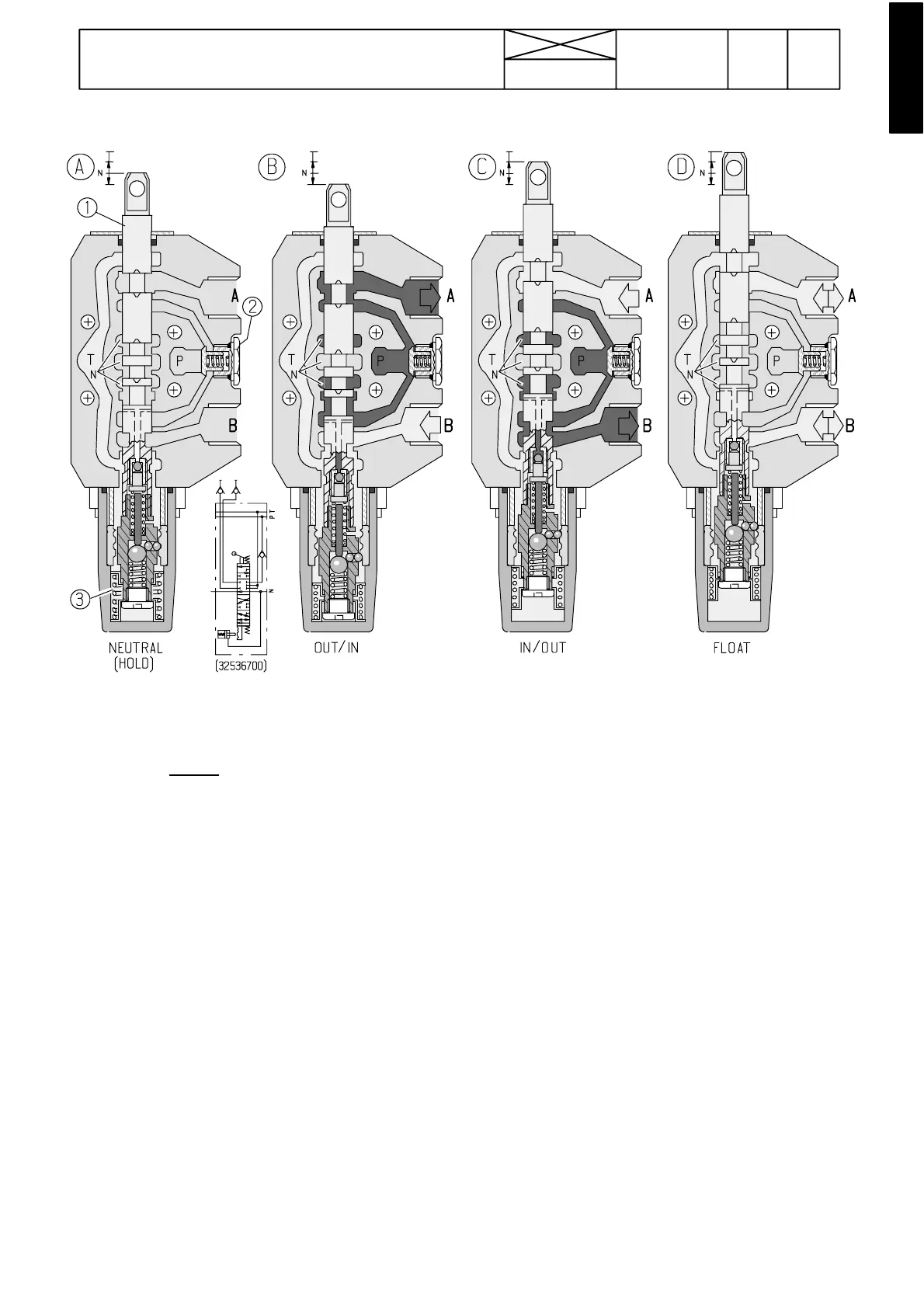

K i c k --- o u t v a l v e

--- Extra equipment (32536700): 2---action, 4 positions (float---

ou t --- ho l d --- i n) k i ck ou t

. Float, out and in---positions can be

locked.

Function:

A: Neutral position: Oil flows from the priority valve (via valve

blocks) through passages N and further to the power lift con-

trol valve. Passages to auxiliary hydraulics (A, B)andthe

non---return valve 2 are closed.

B: Pressure position: When the spool 1 is moved down-

wards, the spool middle part closes the passages N and the

spool upper part opens an oil way to port A. Pressure in pass-

age N increases as in passage P (passages joint together in

the front end plate).

Non---return valve 2 opens and oil flows via port A to the aux-

iliary hydraulics.

Atthesametimethespoolhasopenedareturnpassagefrom

port B to tank passage T. Locking balls lock the spool.

C: When the spool is moved upwards, port B is pressurised

and oil returns via port A.

Pressure return (kick---out) to the neutral position happens

when oil pressure pushes ball+needle at the spool lower end

and releases the locking balls (at a pressure of 14---16 MPa).

The spring spaceis open and allowsoiltobereturnedtopass-

age T. Rest of pressure in the oil space (if greater than 0,2

MPa) can cause returning of the spool to the neutral position.

D: Floating position: Spool 1 has been moved further

upwards. The locking balls lock the spool in position. The

middle passages N open and oil flows through them to the

power lift control valve. Connection between pressure pas-

sage P to ports A and B is closed.

Both ports A and B are connected with tank passage T.

--- When the valve is used as a single---acting valve, an imple-

ment hose should be connected to the upper coupling A.The

return oil flow can be created by moving the spool to the float-

ing position (upwards).

1) Spool

2) Non---return valve

3) Centring springs

Loading...

Loading...