c

e

r

t

i

f

i

e

d

Q

M

-

S

y

s

t

e

m

g

e

p

r

ü

f

t

e

s

Q

M

-

S

y

s

t

e

m

ISO 9001

EN 29001

Installation, Operating, and Maintenance Instructions

Series 64.1

VAT Vakuumventile AG, CH-9469 Haag, Schweiz

Tel ++41 81 771 61 61 Fax ++41 81 771 48 30 Email reception@vat.ch http://www.vatvalve.com

225590EE

2005-04-26

16/16

9.4 User Information and Recommendations

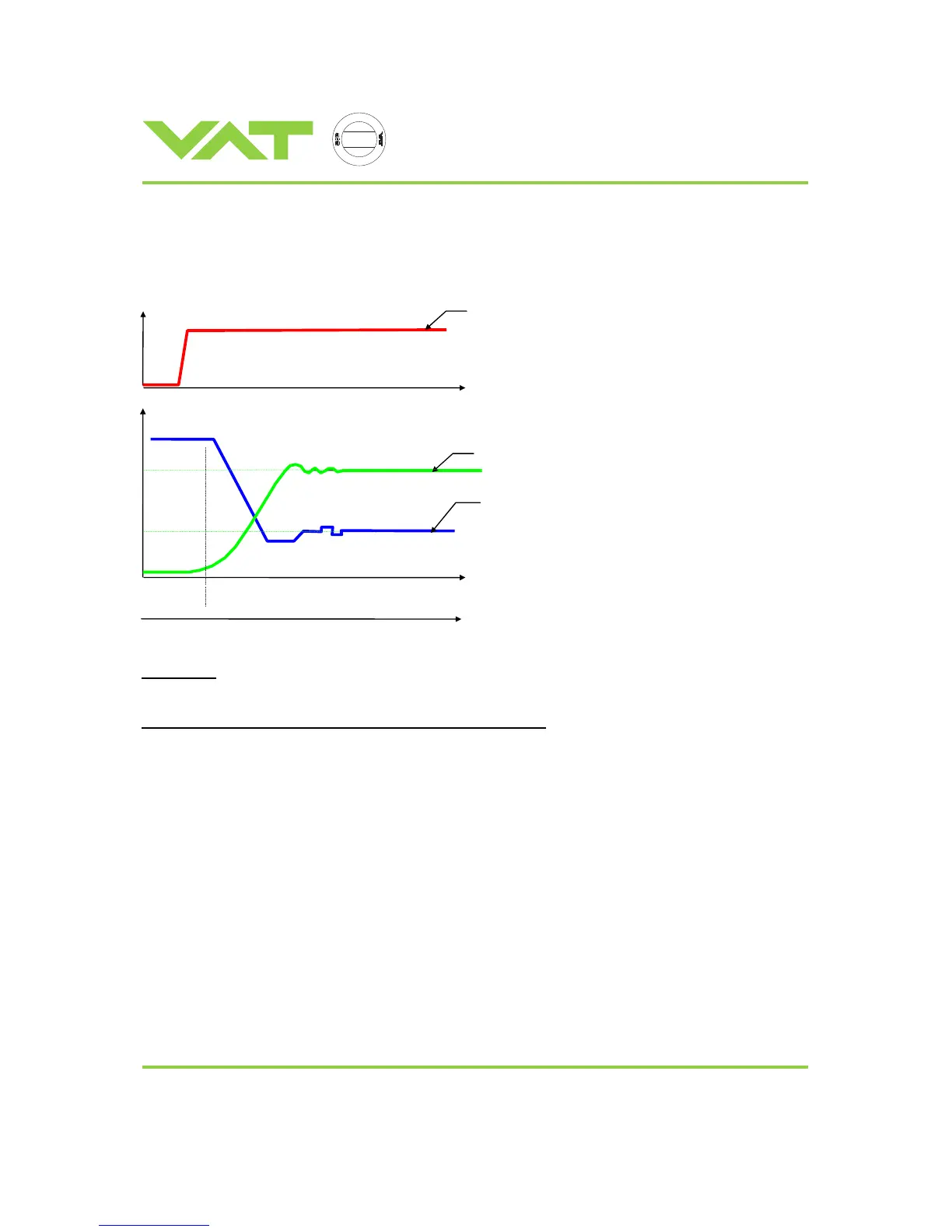

9.4.1 Operation sequence of PM controller

Initialization

Prior to pressure control the setup sequence needs to be performed. Please refer to chapter ‚2.3 PM Configuration (setup sequence)‘

Pressure Control Sequence in LOCAL mode or with ‘S:’ Command

Pressure control starts after «PRESSURE MODE» and a «SET POINT» is selected or after a pressure control command is sent to the PM

controller.

9.4.2 How to optimize sensor signal resolution

Full scale signal of the sensor is converted by a 12bit AD converter. The resolution depends therefore on the Voltage Range.

Example: Sensor: 1 Torr full scale, 0 to 10 VDC output;

Required pressure range: 0 to 120 mT

Standard sensor setup on PM: Voltage Range: 0-10V, Display Range: 1, Display Unit: Torr

→ Resolution of PM controller: 1Torr * 0.03% = 0.3mT

Recommended for sensor setup: Voltage Range: 0-2V, Display Range: 0-200, Display Unit: mTorr

→ Resolution of PM controller: 200mTorr * 0.03% = 0.06mT

Valve

Position

Control Mode

Pressure

Valve

OPEN

Gas flow

Loading...

Loading...