819.4496 33

Technical Data

Maximum Fluid Working Pressure 8.3 bar

Air Pressure Operating Range 1.4–8.3 bar

Maximum Air Consumption 4.9 N m

3

/min

Air Consumption

at 4.9 bar/227 l/min 1.68 N m

3

/min (see chart)

Maximum Free Flow Delivery 568 l/min

Maximum Pump Speed 145 cpm

Liters per cycle

3.90

Maximum Suction Lift 5.48 m wet or dry

Maximum Size Pumpable Solids 6.3 mm

* Sound pressure Level at 7 bar, 50 cpm 90 dBa

* Sound Power Level at 7 bar, 50 cpm 103 dBa

* Sound Pressure Level at 4.9 bar, 50 cycles/min 85 dBa

Maximum Operating Temperature 65.5°C

Air Inlet Size 1/2 npt(f)

Fluid Inlet Size. 2 in. Raised Face Flange

ANSI/DIN 50 Flange 2 in. (50 mm)

Fluid Outlet Size. 2 in. Raised Face Flange

ANSI/DIN 50 Flange 2 in. (50 mm)

Wetted Parts Vary by Model. Refer to pages 26–29

Non-wetted External Parts Aluminum,

302, 316 Stainless Steel, Polyester (labels)

Weight Polypropylene Pumps

with Aluminum Air Section: 22 kg

PVDF Pumps

with Aluminum Air Section: 31 kg

Polypropylene Pumps

with Stainless Steel Air Section: 32 kg

PVDF Pumps

with Stainless Steel Air Section: 41 kg

Santoprene

®

is a registered trademark of the Monsanto

Co.

* Sound pressure levels measured with the pump

mounted on the floor, using Rubber Foot Kit 819.4333.

Sound power measured per ISO Standard 9614–2.

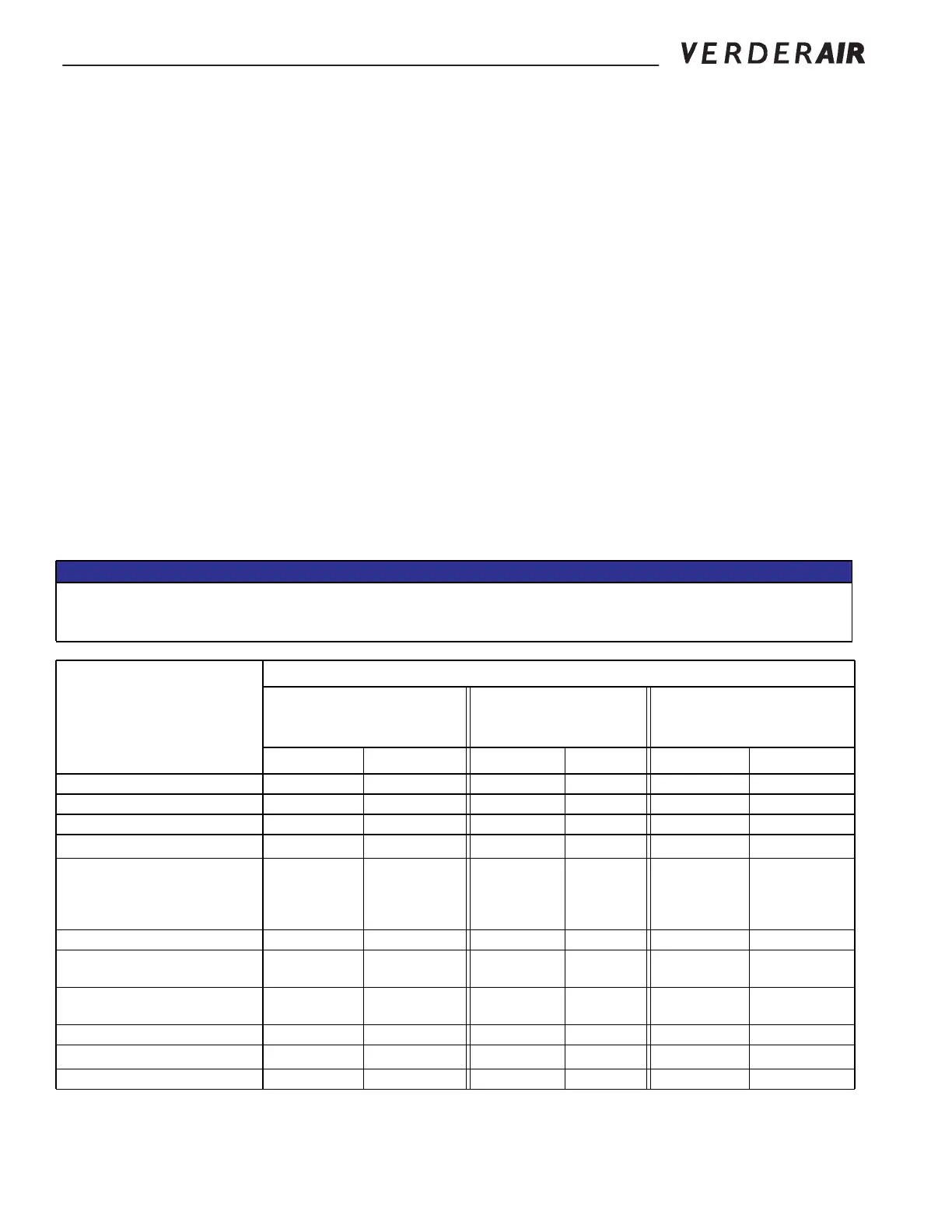

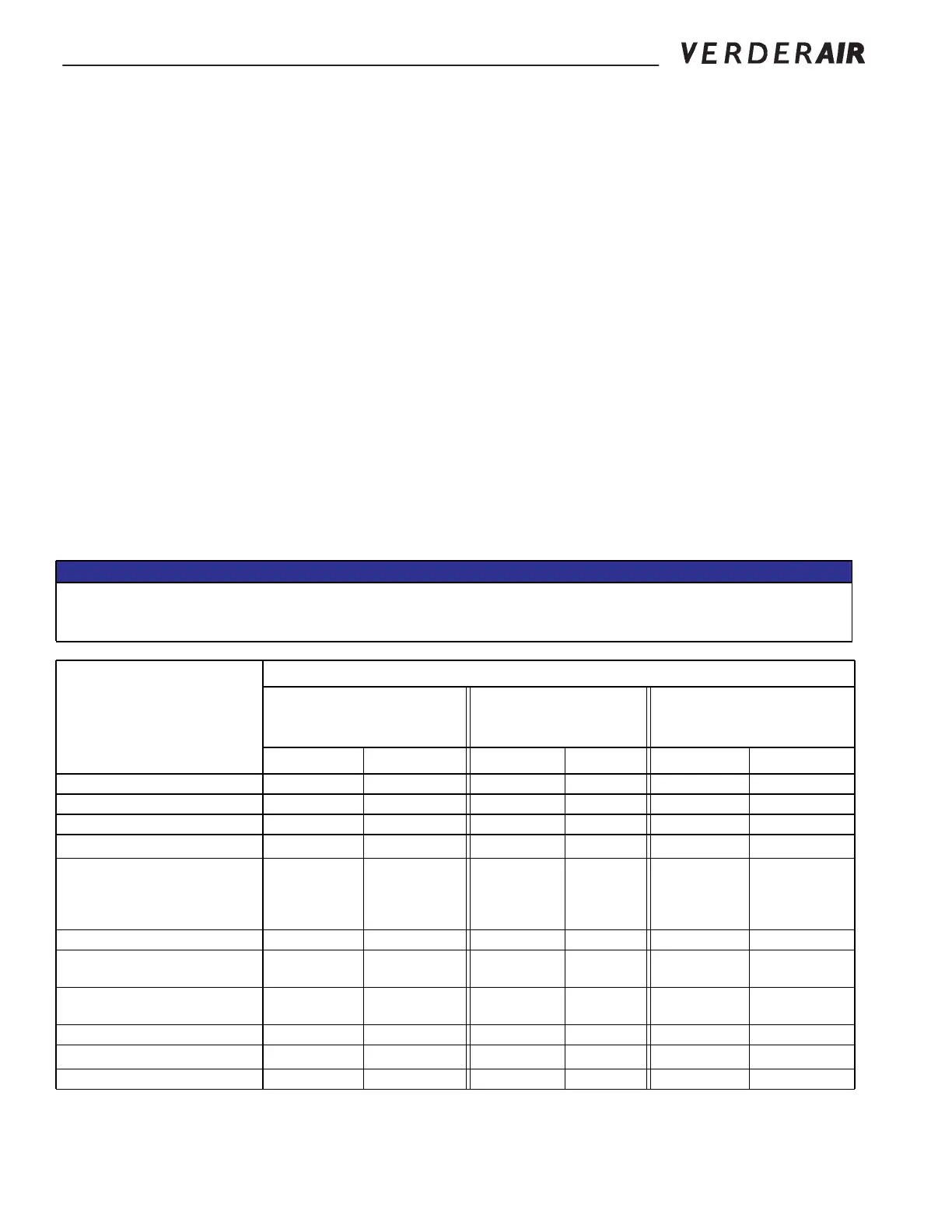

Fluid Temperature Range

* The maximum temperature listed is based on the ATEX standard for T4 temperature classification. If you are

operating in a non-explosive environment, FKM fluoroelastomer’s maximum fluid temperature in aluminum or

stainless steel pumps is 320°F (160°C).

NOTICE

Temperature limits are based on mechanical stress only. Certain chemicals will further limit the fluid temperature

range. Stay within the temperature range of the most-restricted wetted component. Operating at a fluid temperature

that is too high or too low for the components of your pump may cause equipment damage.

Diaphragm/Ball/Seat Material

Fluid Temperature Range

Aluminum, Hastelloy, or

Stainless Steel Pumps

Polypropylene or

Conductive

Polypropylene Pumps PVDF Pumps

Fahrenheit Celsius Fahrenheit Celsius Fahrenheit Celsius

Acetal (AC) 10° to 180°F -12° to 82°C 32° to 150°F 0° to 66°C 10° to 180°F -12° to 82°C

Buna-N (BN) 10° to 180°F -12° to 82°C 32° to 150°F 0° to 66°C 10° to 180°F -12° to 82°C

FKM Fluoroelastomer (FK)* -40° to 275°F -40° to 135°C 32° to 150°F 0° to 66°C 10° to 225°F -12° to 107°C

Geolast

®

(GE)

-40° to 150°F -40° to 66°C 32° to 150°F 0° to 66°C 10° to 150°F -12° to 66°C

Polychloroprene overmolded

diaphragm (CO) or Poly-

chloroprene check balls

(CR or CW)

0° to 180°F -18° to 82°C 32° to 150°F 0° to 66°C 10° to 180°F -12° to 82°C

Polypropylene (PP) 32° to 150°F 0° to 66°C 32° to 150°F 0° to 66°C 32° to 150°F 0° to 66°C

PTFE overmolded

diaphragm (PO)

40° to 180°F 4° to 82°C 40° to 150°F 4° to 66°C 40° to 180°F 4.0° to 82°C

PTFE check balls or two-piece

PTFE/EPDM diaphragm (PT)

40° to 220°F 4° to 104°C 40° to 150°F 4° to 66°C 40° to 220°F 4° to 104°C

PVDF (PV) 10° to 225°F -12° to 107°C 32° to 150°F 0° to 66°C 10° to 225°F -12° to 107°C

Santoprene

®

(SP)

-40° to 180°F -40° to 82°C 32° to 150°F 0° to 66°C 10° to 180°F -12° to 82°C

TPE (TP) -20° to 150°F -29° to 66°C 32° to 150°F 0° to 66°C 10° to 150°F -12° to 66°C

Loading...

Loading...