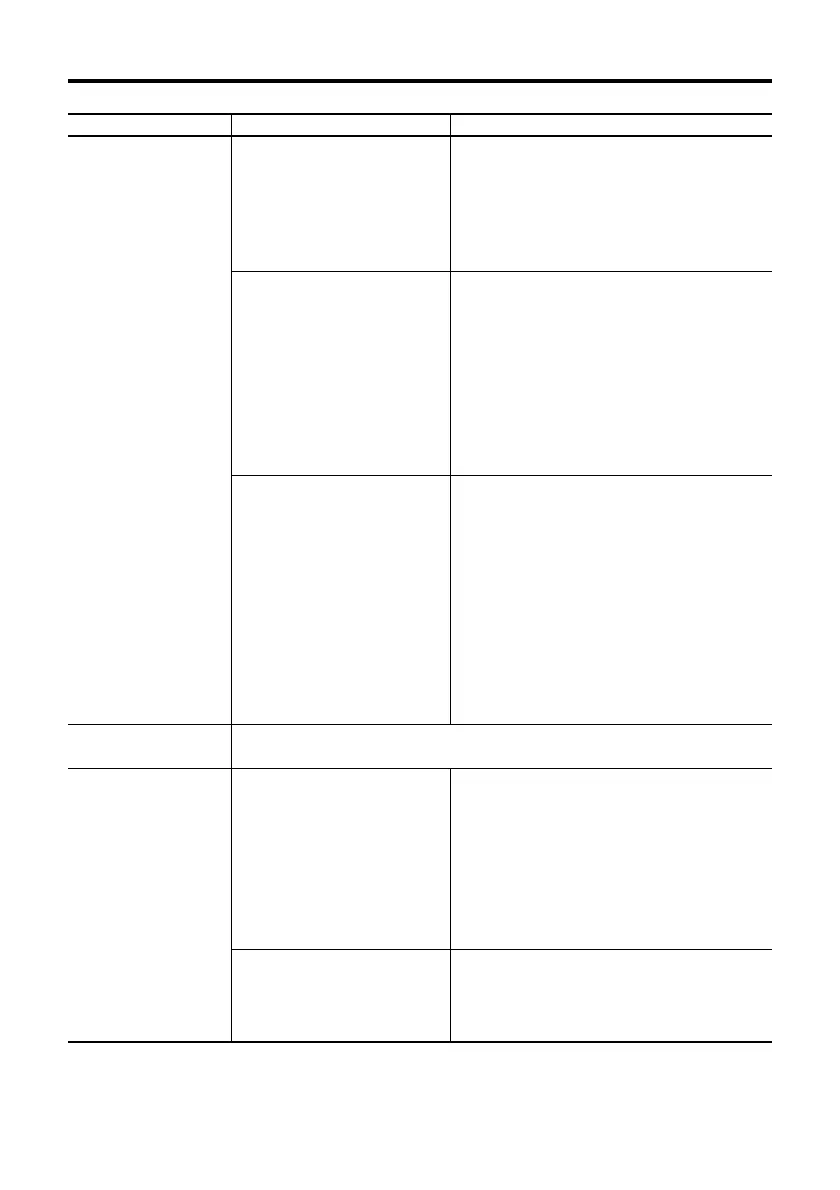

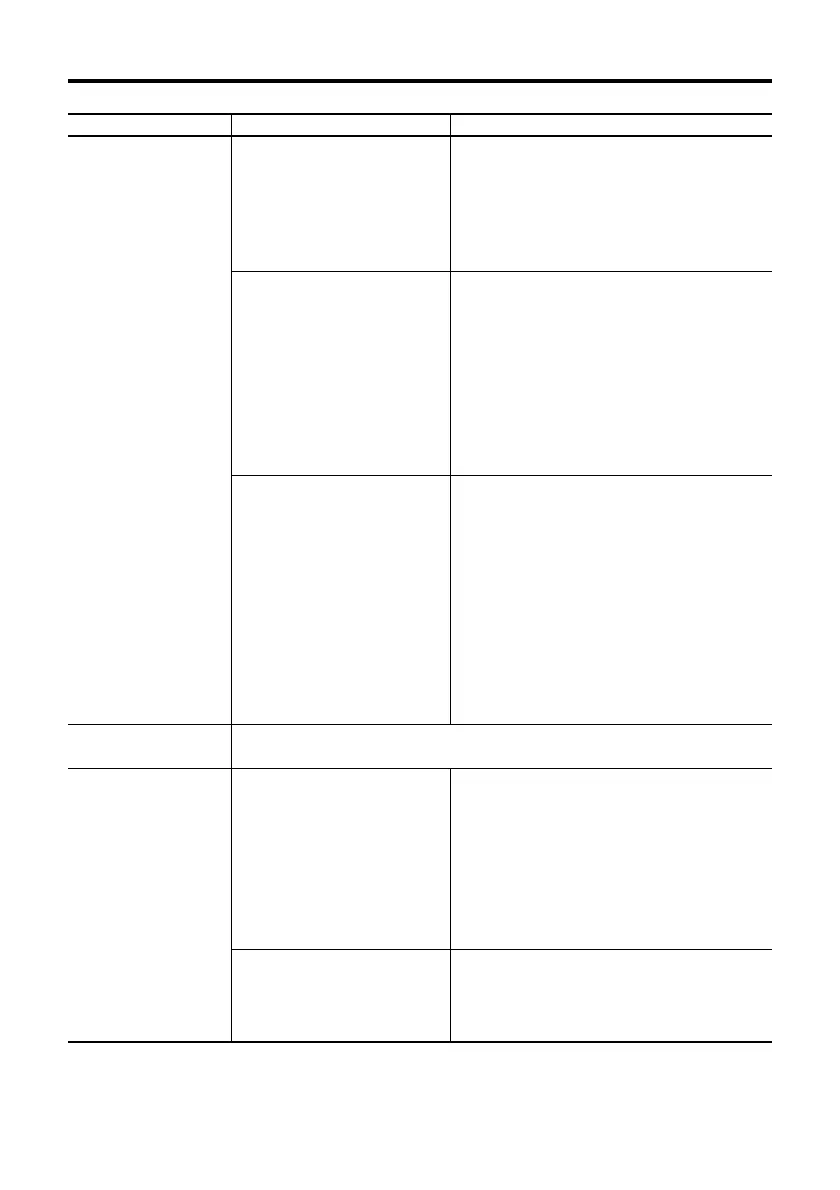

28

Problem

The motor rotates in

the wrong direction.

Motor rotation is

erratic.

Motor start up is

unstable.

Measures

Connect the CW pulse signal line to the

pulse/CW pulse signal input terminal, and

connect the CCW pulse signal line to the

rotation direction/CCW pulse signal input

terminal.

If the motor rotates in a counterclockwise

direction the motor and driver are normal.

Recheck the rotation direction signal levels.

(“photocoupler ON” = clockwise,

“photocoupler OFF” = counterclockwise)

For harmonic geared type and 10:1 of MG

geared type, due to the gear’s construction,

the direction of rotation of the output shaft is

opposite to the direction of rotation of the

motor itself as commanded by pulse input

(Refer to page 16).

Connect the CW pulse signal line to the

rotation direction/CCW pulse signal input

terminal, and connect the CCW pulse signal

line to the pulse/CW pulse signal input

terminal.

The motor will run irregularly if two pulses are

input at the same time.

Make sure the motor shaft and load are

securely attached and properly aligned.

Recheck the operating conditions, and if

necessary lighten the load.

Check points

7. In 2-pulse input mode

(pulse input mode switch

in the 2P position) are the

CW and CCW pulse signal

lines connected

backwards?

8. In 1-pulse input mode

(pulse input mode switch

in the 1P position) leave

the rotation direction/CCW

pulse signal input terminal

unconnected and try

inputting a pulse signal to

the pulse/CW pulse signal

input terminal.

9. Is harmonic geared type or

gear ratio of 10:1 of MG

geared type used?

10. While in 2-pulse input

mode (pulse input mode

switch in the 2P position)

are the both of pulse/CW

pulse and rotation

direction CCW pulse

signal input at the same

time?

11. Are the motor shaft and

load properly aligned? Is

the load too heavy for the

motor?

First check items 5, 6, 7 and 8.

Loading...

Loading...