32

• Maximum holding torque refers to the holding torque at motor standstill when the rated current is supplied to the

motor (5-phase excitation), with consideration given to the permissible strength of the gear. Use this value to

compare motor torque performance. When using the motor with the dedicated driver, the driver’s “Automatic

current cutback” function at motor standstill reduces maximum holding torque by approximately 50%.

• The power source input current value represents the maximum current. (The input current varies according to the

pulse frequency.)

• Permissible torque is the marginal value of the mechanical strength of the gear unit. Use the product with a total

torque (load and acceleration) less than the permissible torque.

• Maximum overhung load indicates the value measured at 10mm (0.39in.) from the tip of the gear output shaft.

Note

•

Do not measure insulation resistance or perform the dielectric withstand test while the motor and driver are connected.

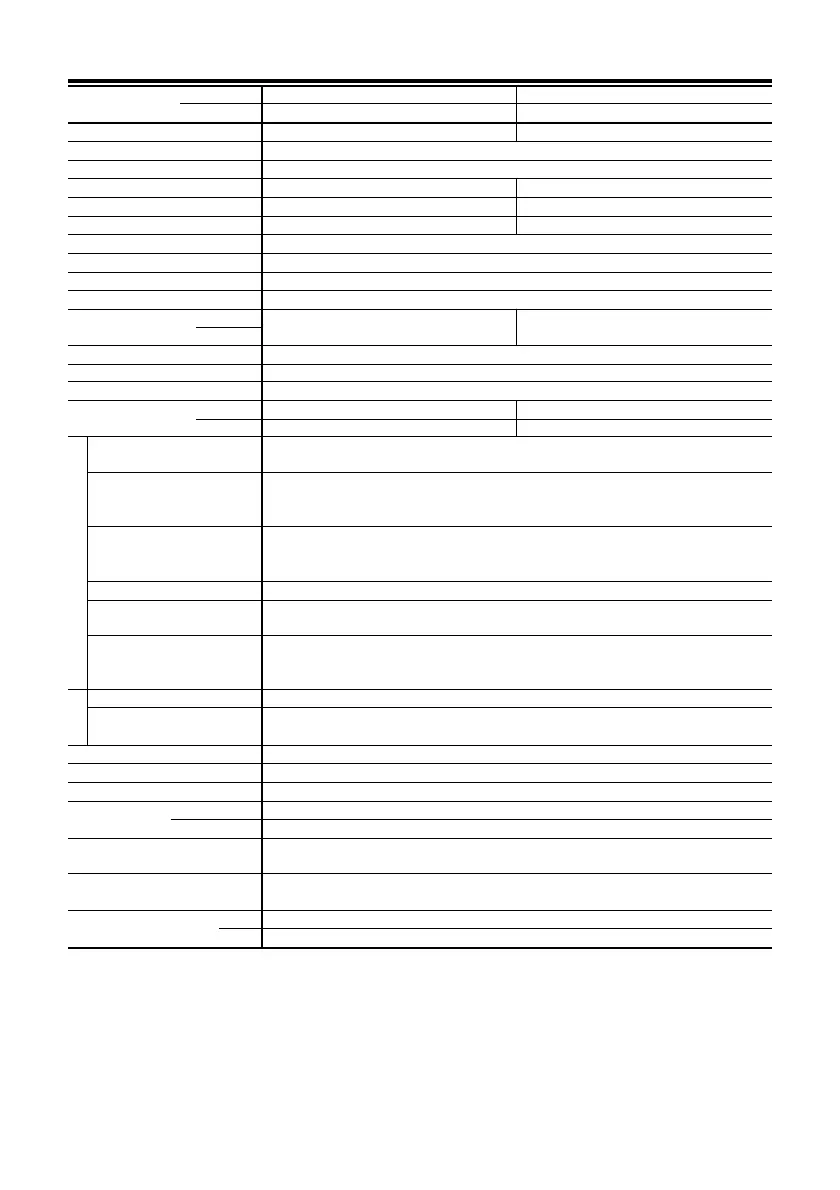

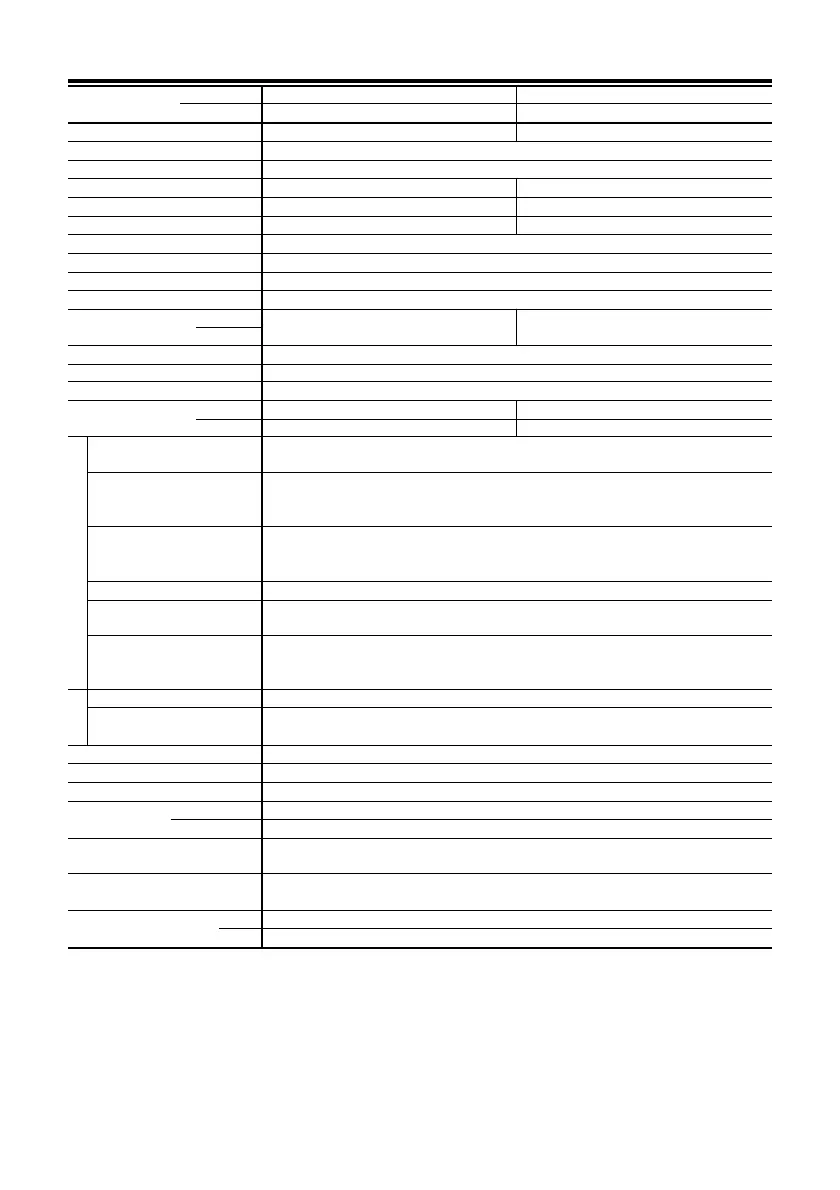

PMC33A1-HG50

PMC33B1-HG50

1.5 (213)

Package Model

Single Shaft

Double Shaft

Maximum Holding Torque

Rotor Inertia

Rated Current

Basic Step Angle

Gear Ratio

Permissible Torque

Maximum Torque

Permissible Thrust Load

Permissible Overhung Load N (lb.)

Direction of Gear Shaft Rotation

Permissible Speed Range

(Gear Output Shaft Speed)

Insulation Class

Power Source

Output Current

Excitation Mode

N·m (oz-in)

kg·m

2

(oz-in

2

)

A/phase

N·m (oz-in)

N·m (oz-in)

N (lb.)

12×10

-7

(0.066)

0.35

Input Signal Circuit

• Pulse Signal

(CW Pulse Signal)

• Rotation Direction Signal

(CCW Pulse Signal)

• Step Angle Signal

• All Windings Off Signal

•

Automatic Current Cutback

Release Signal

Output Signal Circuit

• Excitation Timing Signal

Functions

Indication (LED)

Driver Cooling Method

Mass

Insulation Resistance

Dielectric Strength

Ambient Temperature Range

Input Signals

Output Signals

Motor kg (lb.)

Driver kg (lb.)

Motor

Driver

PMC33A1-HG100

PMC33B1-HG100

2.0 (284)

0.0144°

50:1

1.5 (213)

2.0 (284)

0.0072°

100:1

2.0 (284)

2.8 (397)

Class B [130°C (266°F)]

DC24V±10% 0.7A or DC36V±10% 0.7A

0.35

100 (22)

200 (45)

Opposite to motor

0~70r/min

Photocoupler input, Input resistance 220Ω, Input current 20mA maximum

Signal voltage Photocoupler ON: +4~+5V, Photocoupler OFF: 0~+0.5V

Step command pulse signal (CW step command signal at 2-pulse input mode)

Pulse width: 5µs minimum, Pulse rise/fall: 2µs maximum

Motor moves when the photocoupler state changes from ON to OFF.

Rotation direction signal Photocoupler ON: CW, Photocoupler OFF: CCW

(CCW step command signal at 2-pulse input mode Pulse width: 5µs minimum, Pulse rise/fall: 2µs maximum

Motor moves when the photocoupler state changes from ON to OFF.)

Full Step at “photocoupler OFF” Half Step at “photocoupler ON”

When in the “photocoupler ON” state, the current to the motor is cut off and the motor shaft can be rotated manually.

When in the “photocoupler OFF” state, the current level set by the RUN switch is supplied to the motor.

When in the “photocoupler ON” state, the “Automatic Current Cutback” function at motor standstill is disabled.

When in the “photocoupler OFF” state, the “Automatic Current Cutback” function at motor standstill is activated.

(approximately 100ms after motor stops)

Photocoupler, Open-Collector Output External use condition: 24VDC maximum, 10mA maximum

Signal is output every time the excitation sequence returns to the initial “0”. (Photocoupler: ON)

Full step: Signal is output every 10 pulses, Half step: Signal is output every 20 pulses

Automatic current cutback, All windings off, Pulse input mode switch

Power Input

Natural Ventilation

0.21 (0.47)

0.025 (0.06)

100MΩ minimum under normal temperature and humidity, when measured by

a DC500V megger between the motor coils and the motor casing.

Sufficient to withstand 0.5kV, 60Hz applied between the motor coils and

casing for one minute, under normal temperature and humidity.

0°C~+40°C (+32°F~+104°F)

0°C~+40°C (+32°F~+104°F)

Full Step

Half Step

A/phase

Full Step

Half Step

0~35r/min

0.0144°/step

0.0072°/step

0.0072°/step

0.0036°/step

Loading...

Loading...