I-751.Europe / European Alarm Check Valve Stations / Installation, Maintenance, and Testing Manual

INITIAL SYSTEM SETUP

WARNING

• Series 751 FireLock

™

European Alarm Check Valve Stations and

supply piping shall be protected from freezing temperatures and

mechanical damage.

• For proper operation of alarms in a wet system, it is important to

remove all air from the system. Auxiliary drains may be required

to release all trapped air from the system.

• Alarms and electrical panels that are controlled by an alarm flow

switch on the riser shall not be interrupted. If alarm activation

is possible, notify local fire companies that the system is being

serviced.

Failure to follow these instructions could cause improper valve

oper ation, resulting in death or serious personal injury and property

damage

Step 1:

Open the system main drain valve (Item 9). Confirm that the system is

drained.

Step 2:

Close the system main drain valve (Item 9).

Step 3:

Confirm that system drains are shut and the system is free of leaks.

Step 3a:

Confirm that the system has been depressurized. The gauges should

indicate zero pressure.

Step 4:

Open the remote system test valve (inspector’s test connection) and any

auxiliary drains to remove all air from the system.

Step 5:

Close the alarm line ball valve (Item 13) to prevent alarms from

operating while the system is filling. FOR FG AND SBSC TRIM: Close

the alarm line monitoring ball valve(s)– Item 14a on page 7.

Step 6:

Open the water supply main control valve (Item 3) slowly. Allow the

system to fill with water completely. Allow water to flow from the remote

system test valve (inspector’s test connection) and any auxiliary drains

until all trapped air is removed from the system.

Step 7:

Close the remote system test valve (inspector’s test connection) and any

auxiliary drains. NOTE: The system pressure gauge (Item 7) reading

should be equal to or greater than the water supply pressure gauge

(Item 5) reading.

Step 8:

Open the water supply main control valve (Item 3) fully.

WARNING

• The alarm line ball valve or alarm line monitoring ball valve(s)

shall remain in the open position to allow alarms to activate.

Failure to follow this instruction will prevent alarms from activating,

resulting in death or serious personal injury and property damage.

Step 9:

Open the alarm line ball valve (Item 13). Lock the ball valve, if required.

FOR FG AND SBSC TRIM: Open the alarm line monitoring ball valve(s)–

Item 14a on page 7.

Step 10:

Confirm that all valves are in their normal operating positions (refer to

the table below).

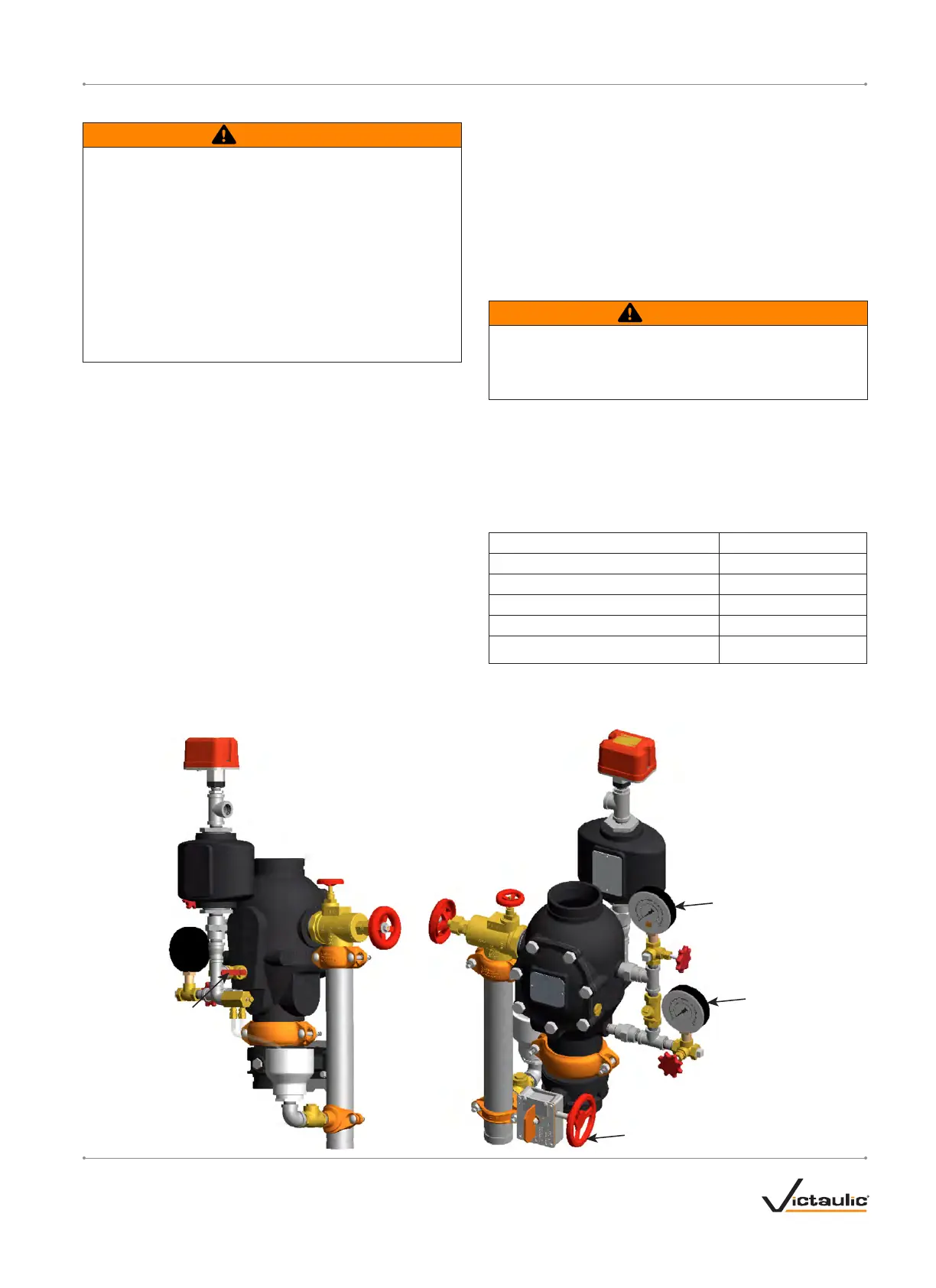

Valve Normal Operating Position

Alarm Line Ball Valve (Lockable) Open

Water Supply Main Control Valve Open

System Main Drain Valve Closed

System Test Valve Closed

Alarm Line Monitoring Ball Valve(s) -

FG and SBSC Trim Only

Open

Step 11:

Notify the authority having jurisdiction, remote station alarm monitors,

and those in the affected area that the system is in service.

Water Supply Main

Control Valve

(Item 3, Steps 5 & 7)

Alarm Line

Ball Valve

(Item 13,

Steps 4 & 8)

System

Pressure Gauge

(Item 7, Step 6)

Water Supply

Pressure Gauge

(Item 5, Step 6)

VDS, CE, UKCA, FM, EAC VERSION SHOWN

I-751.Europe_10REV_G

Loading...

Loading...