Set-up

10

Mechanical Room

During the early stages of new home design, we recommend that proper

consideration be given to constructing a separate mechanical room dedicated to

gas- or oil-fired equipment including domestic hot water storage tanks.

The boiler must be located in a heated indoor space, near a floor drain, and as close

as possible to the v ertical chimney or vent.

Whenever possible, install boiler near an outside wall so that it is easy to duct fresh

air directly to the boiler area. In addition, do not use exhaust fans in the boiler room

and do not install the boiler in rooms with refrigeration equipment. This equipment

requires uncontaminated outside air for safe operation - do not install where

chemicals are stored or in a room with negative pres sure. See section entitled

“Combustion Air Supply” starting on page 12 for further details regarding the

above.

Locate boiler on f looring capable of supporting the weight of the boiler filled with

water. Pour a concrete pad if necessary. Ensure that the boiler location does not

interfere with the proper circulation of combustion and ventilation air within the

mechanical room.

The maximum room temperature of the mechanical room where the boiler is located

must not exceed 104°F/40°C.

Standard Equipment

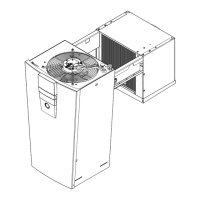

H Wet bas e sectional cast iron heat

exchanger with stainless steel burners

H Induced draft blower and pressure

switch

H Electronic ignition

H 24 VAC redundant seat gas valve

H Boiler fully insulated with 1½”/38 mm

fiberglass wrap-around blanket

H Boiler control panel with adjustable

operating limit (122°F - 194°F), fixed

high limit (248°F) and temperature

gage

H Pump aquastat to turn pump on at

104°F / 40°C and off at 91°F / 33°.

H One 120/24 VAC transformer

H 30 psig pressure relief valve, pressure

gage and fittings

H One cleaning brush

Boiler comes standard equipped with

30 psig ASME-rated pressure relief

valve. This 30 ps ig pressure relief valve

may be exchanged at the job sit e with a

50 psig ASME-rated pressure relief

valveonlybystrictlyobservingthe

minimum relief valve capacity in lb/h

marked on the nameplate. The

maximum allowable working pressure is

50 psig.

Be aware that best overall performance

is achieved when all components are

properly sized. Sizing of the required

circulation pump according t o the pipe

layout and calculation of a proper

volume expansion tank is vital to obtain

the system’s peak performance.

5167 450 v1.4

Loading...

Loading...