Connections

26

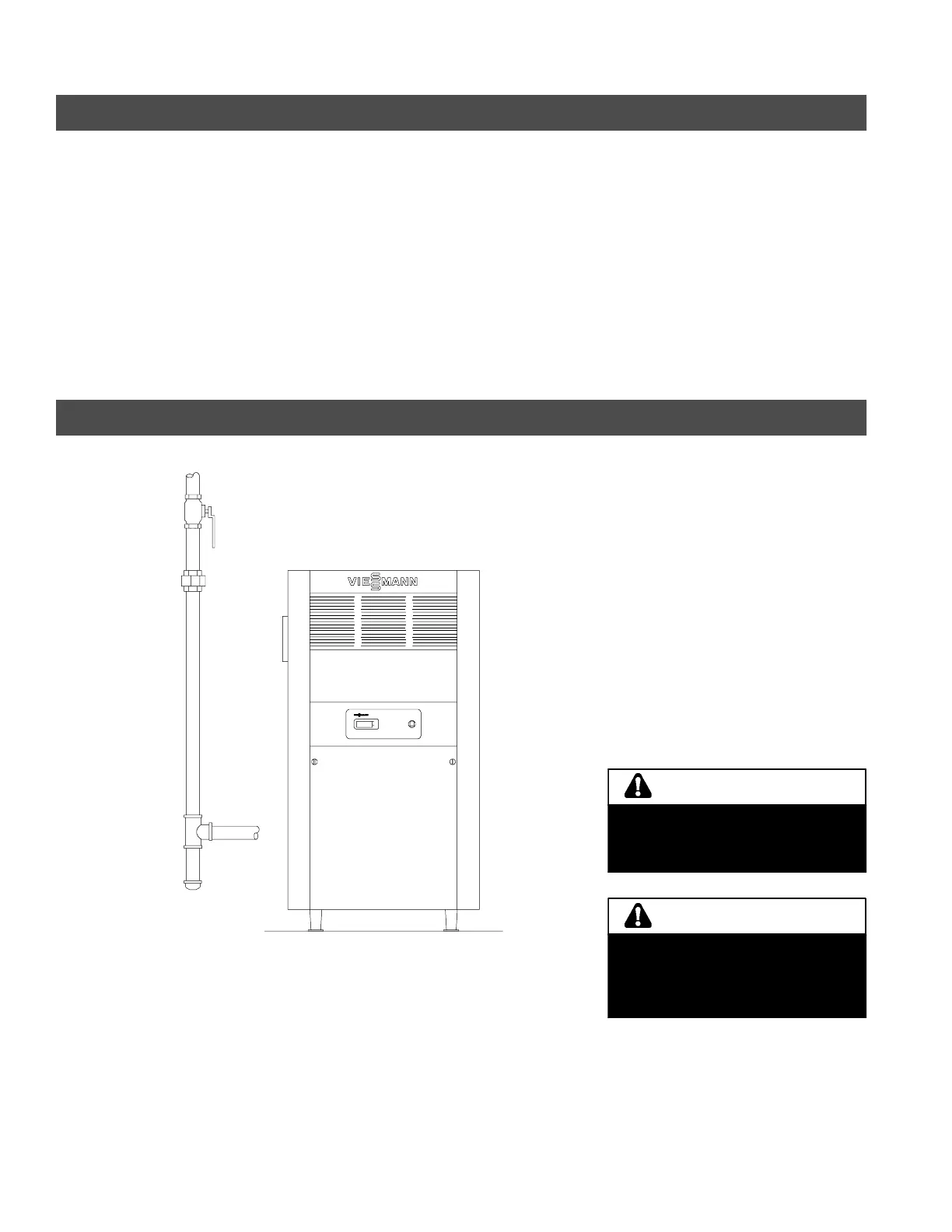

Gas Piping

Before connecting gas boiler to gas line,

install main gas shut-off valve, union,

and capped drip leg (see Fig. 11 below).

Size gas supply piping to boiler

according to local utility requirements.

Identify the main shut-off valve as such

with a tag and f amiliarize owner of

boiler with this valve.

Support piping by proper suspension

method. Piping must not rest on or be

supported by boiler.

Testing Gas Pipe

The boiler and its individual shut-off

valve must be disconnected from the

gas supply piping system during any

pressure testing of that system at

pressures in excess of 0.5 psig (3.5

kPa).

The boiler must be isolated from the

gas supply piping system by closing its

individual manual shut-off valve during

any pressure testing of the gas supply

piping system at a test pressure equal

to or less than 0.5 psig (3.5 kPa).

Gas manifold has been factory-tested.

Leak test must be repeated during initial

trial operation of burner by mechanical

contractor.

5167 450 v1.4

C

F

Ground joint

union

Approved manual

gas shut-off valve

Sediment

trap

Min. gas supply pressure

4.5 “w.c. for natural gas

12 “w.c. for L.P. gas

Fig. 11

Never check for gas leaks with an

open flame. Us e approved s pray liquid

or soap water solution for bubble

test.

CAUTION

Maximum gas supply pressure is

14“w.c./0.5psig.Boilermustbe

disconnected from gas piping for

piping pressure tests above 14 “w.c.

/0.5psig.

WARNING

Loading...

Loading...