SECTION TSM 628 ISSUE A PAGE 5 OF 8

6. Carefully remove rotor and shaft to avoid damaging

bracket bushing. If damaged or worn, remove bushing.

7. Remove bracket lip seal (Item 18).

8. Loosen two radial setscrews in flange of bearing housing

and with a spanner wrench remove the outer end cap

with lip seal and outer bearing spacer collar. Note: G

size uses sealed bearings and does not have a lock

washer, lip seals or half-round rings.

9. Remove the double row ball bearing, lip seal and inner

bearing spacer collar from the bearing housing. Note:

G size uses sealed bearings and does not have a lock

washer, lip seals or half-round rings.

10. Remove the rotary member of the mechanical seal from

the rotor shaft. Remove the seal seat from the bracket.

11. Clean all parts thoroughly and examine for wear and

damage. Check lip seals, ball bearing, bushings, and

idler pin and replace if necessary. Check all other parts

for nicks, burrs, excessive wear and replace if necessary.

Wash bearings in clean solvent. Blow out bearings with

compressed air. Do not allow bearings to spin; turn them

slowly by hand. Spinning bearings will damage race and

balls. Make sure bearings are clean, then lubricate with

light oil and check for roughness. Roughness can be

determined by turning outer race by hand.

Note: G size uses sealed bearings

12. Casing can be checked for wear or damage while

mounted on bracket.

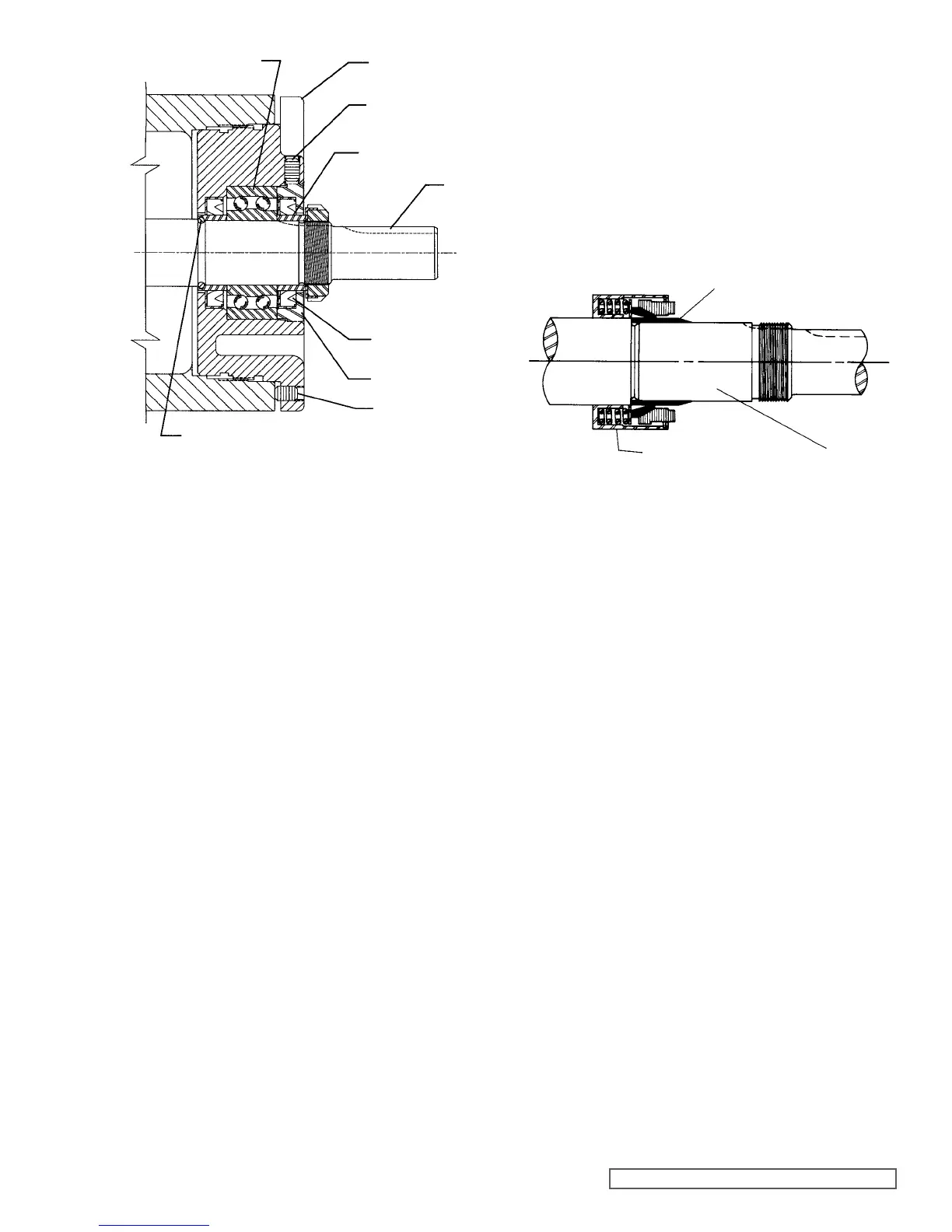

HALF ROUND

RINGS

FIGURE 4

END CAP

LIP SEAL

SPACER COLLAR

SETSCREW

SHAFT

SETSCREW

BEARING HOUSING

BALL BEARING

1. Install bracket bushing. If bracket bushing has a

lubrication groove, install bushing with groove at 6.00

o’clock position in bracket. If carbon graphite, Refer to

Installation of Carbon Graphite Bushings, page 6.

Make sure slots in the face of the bushing are towards

rotor end of the bracket.

ASSEMBLY

2. Clean rotor shaft and seal housing bore. Make sure they

are free of dirt, grit and scratches. Gently radius leading

edge of shaft diameter over which seal is to be placed.

Never touch mechanical seal faces with anything except

clean hands or clean cloth. Minute particles can scratch

the seal faces and cause leakage.

3. Place tapered installation sleeve on the shaft. Coat

tapered sleeve and inside of the rotary member

with a generous quantity of light oil. Grease is not

recommended. Start rotary member on shaft and over

tapered sleeve. Refer to Figure 5.

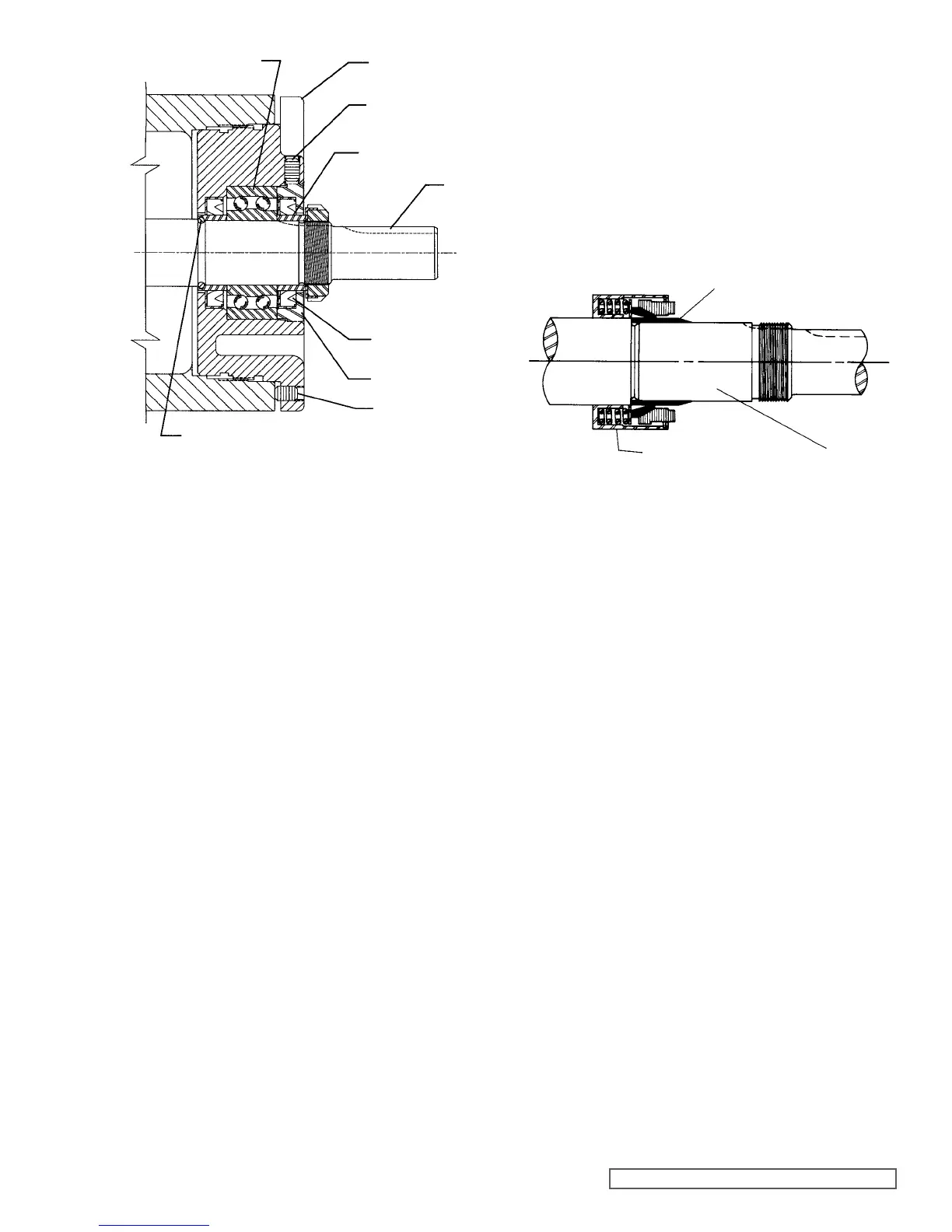

FIGURE 5

TAPERED INSTALLATION SLEEVE

SHAFT

MECHANICAL SEAL

ROTARY MEMBER

4. Move rotary member all the way on the rotor shaft until

it is against the rotor hub. If the seal uses setscrews to

secure the seal to the shaft, tighten the setscrews once

the seal is in place. Some PTFE seals are equipped with

holding clips which compress the seal springs. Remove

holding clips to release springs after seal is installed on

shaft.

5. Lubricate outer diameter of seal seat gasket with oil.

Press seal seat into bore until back, unlapped face

bottoms in bore. Make sure the seat anti-rotation pins

are aligned with slots in the bracket bushing.

6. Coat rotor shaft and face of mechanical seal with light

oil. Start end of shaft in bracket bushing turning from

right to left, slowly pushing rotor in casing.

7. Coat idler pin with light oil and place idler and bushing

on idler pin in head. If replacing with carbon graphite

bushing, Refer to installation of Carbon Graphite

Bushings, page 6.

8. Using a .010 to .015 inch head gasket, install head and

idler assembly on pump. Pump head and casing were

marked before disassembly to insure proper reassembly.

If not, be sure idler pin, which is offset in pump head,

is positioned toward the equal distance between port

connections to allow for proper flow of liquid through

pump. If pump is equipped with jacketed headplate,

install at this time along with new gasket.

9. Tighten head capscrews evenly.

10. Install bracket lip seal (Item 18, lips toward head end).

11. Slide inner spacer collar over shaft with recessed end

facing rotor. G, H and HL size bearing spacer collars are

not recessed.

Place pair of half round rings on shaft and slide inner

bearing spacer collar over half round rings to lock them

in place. There is no pair of half round rings on the G, H

and HL size pumps.

Loading...

Loading...