38

Service Procedures

HFC134a service Information (continued)

• Care must be taken to minimize moisture from

entering HFC134a system. Do not leave

compressor or system open to atmosphere for

more than 10 minutes. Excessive moisture in

HFC134a system will react with compressor oil

and generate acid.

• Compressor must be replaced when performing

low side leak repair..

• Drier filter must always be replaced with service

drier filter. Important: Un-brazing drier filter

from tubing will drive moisture from desiccant

and into system, causing acids to form. Do not

un-braze filter drier from tubing. If CFC12

service drier was installed in HFC134a system,

drier could overload due to excessive moisture.

• HFC134a compatible copper tubing must be

used when replacing tubing.

• Avoid system contamination by using an

evaporating oil when flaring, swagging, or

cutting refrigeration tubing.

HFC134a is alternative for CFC12.

HFC134a has an ozone depletion potential (ODP)

factor of 0.0 and a global warming potential (GWP)

factor of 0.27. HFC134a is not flammable and has

acceptable tonicity levels. HFC134a is not

interchangeable with CFC12. there are significant

differences between HFC1134a and CFC12 which

must be considered when handling and processing

refrigerant system.

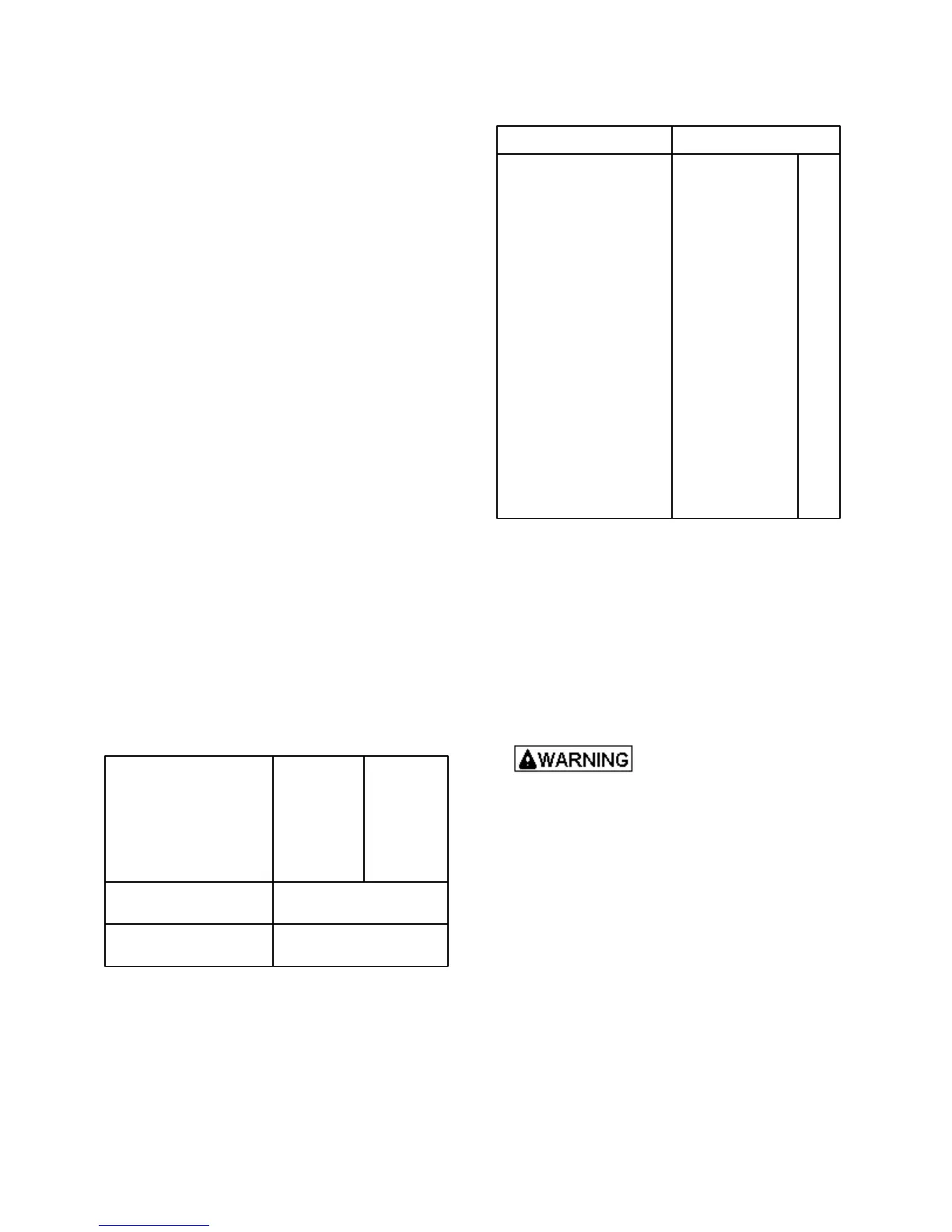

Comparison of CFC12 AND HFC134a

Properties

Properties / Characteristics CFC12 HFC134a

Ozone Depletion Potential 1.0 0.0

Global Warming Potential 3.2 0.27

Molecular Weight 121 102

Boiling Point at 1 Atmosphere -22 F (-30 C) -15 F (-126 C)

Vapor Pressure at 77 F (25 C) 80 psig 82 psig

Liquid Density at 77 F (25 C) 82 lb/ft 75 lb/ft

Flammability No No

High-side System operating HFC134a approximately 3 psig

Pressure at 65 F (18 C) Higher than CFC12

Low-side System operating HFC134a approximately 2 psig

Pressure at 65 F (18 C) Lower than CFC12

Health, Safety, and Handling

Health, safety, and handling considerations for

HFC134a are virtually no different than those for

CFC12.

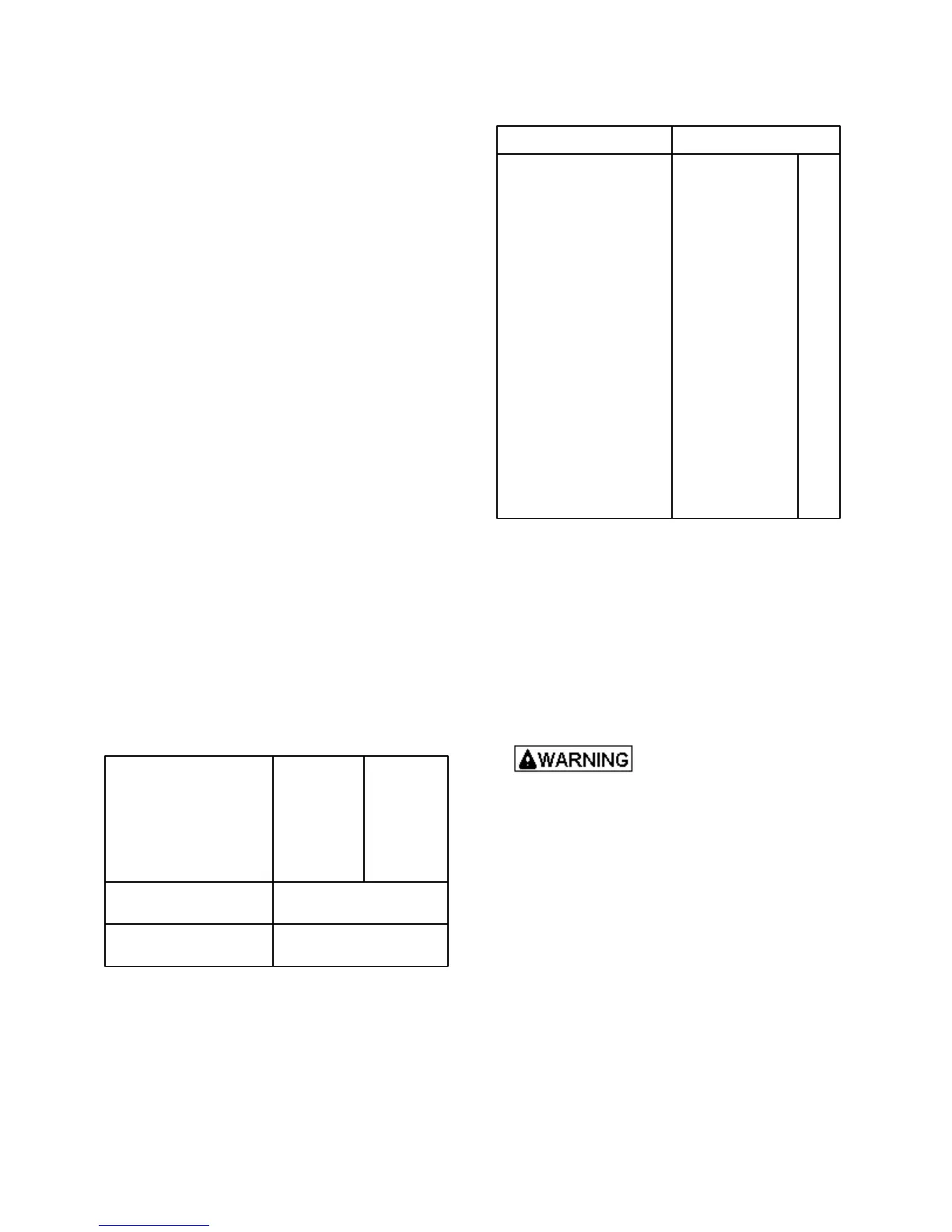

Health, Safety, and Handling CFC12 HFC134a

Allowable overall exposure limit 1,000ppm Same

Vapor exposure to skin No effect Same

Liquid exposure to skin Can cause frostbite Same

Vapor exposure to eye Slight eye irritant Same

Liquid exposure to eye Can cause frostbite Same

Above minimum exposure limit Can cause Asphyxia- Same

tion, Tachycardia,

and Cardia Anthythmia

Safety and handling Wear appropriate skin Same

and eye protection.

Use with adequate

ventilation.

Spill management Remove or extinguish Same

ignition or combustion

sources. Evacuate or

ventilate area.

Fire explosion hazards May decompose if Same

contact with flames

and heating elements

Container may explode

if heated due to

resulting pressure rise.

Combustion products

are toxic.

Disposal procedures Recycle or reclaim Same

Replacement Service Compressor

HFC134a service compressor will be charged with

ester oil and pressurized with dry nitrogen. Before

replacement compressor is installed, pull out 1 rubber

plug. A pop from pressure release should be heard.

If a pop sound is not heard, do not use compressor.

Positive pressure in compressor is vital to keep

moisture out of ester oil. Do not leave compressor

open to atmosphere for more than 10 minutes.

Compressor Testing Procedures

To avoid death or severe

personal injury, never use

oxygen, air or acetylene for

pressure testing or clean out of refrigeration

system. Use of oxygen, air or acetylene may result

in violent explosion. Oxygen may explode on

contact with oil and acetylene will spontaneously

explode when under pressure.

Refer to Technical Date Sheet “Temperature and

Relationship Chart” for operating watts, test points,

and temperature relationship test for unit being tested

• Temperature testing is accomplished by using 3

lead thermocouple temperature tester in specific

locations. Test point “T-1” is outlet on

evaporator coil and “T-2” inlet. Test point”T-3”

is suction tube temperature midway between

where armaflex ends and suction port of

compressor (approximately 12 inches from

compressor).

Loading...

Loading...