SIMPLY INIMITABLE.

15

15

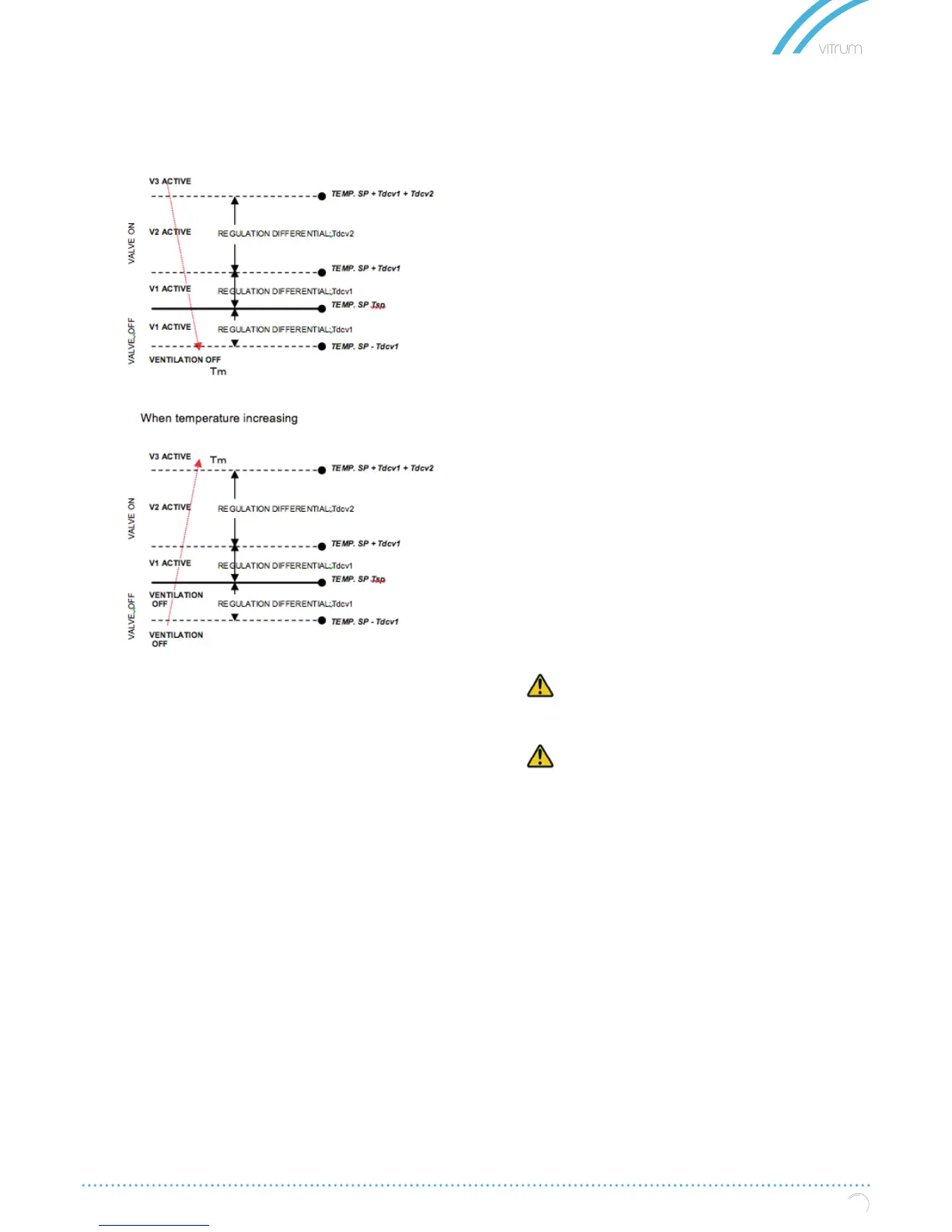

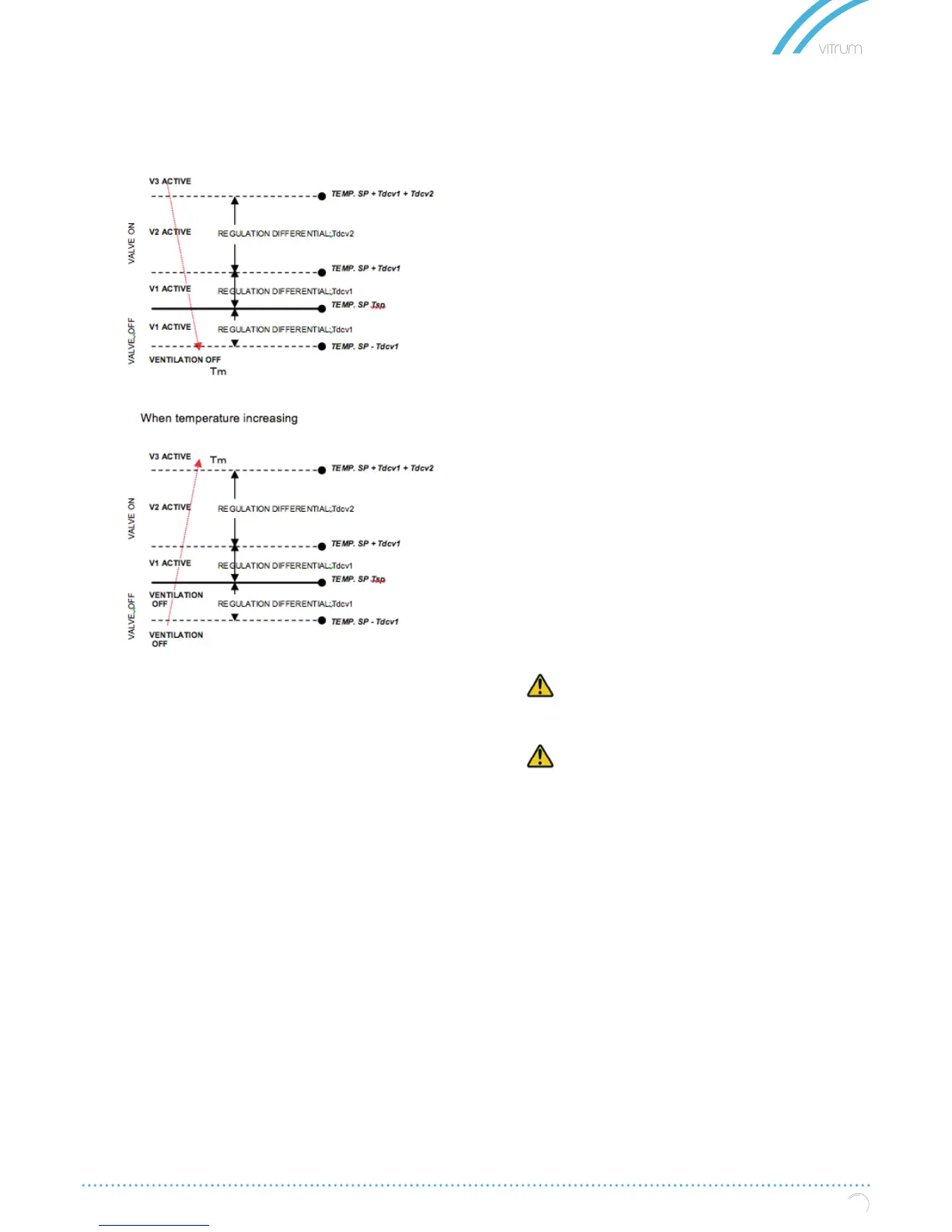

Control logic for a 3 speed fan coil in cooling:

When temperature decreasing

Where:

Tsp : Target setpoint temperature

Tdcv1 : regulation di erential in cooling for V1 Speed

Tdcv2 : regulation di erential in cooling for V2 Speed

Tm : Actual measured temperature

18. Fan coil control %

(or generic continuous control)

19. Temperature probe failure / out of

range measurement

Logic and parameters are the same used in On/o

with PWM control mode; the di erence is that now

the proportional value is sent to the bus via a 1 byte

object format as a % value from 0% to 100%.

This mode is useful to control fan coils (selecting 2

or 4 pipes) or generic proportional actuators as valve

drivers only linking the 1 byte communication object

and avoiding to link the valve objects.

CONTINUOUS CONTROL object

This 1 Byte object send % control value to actuator.

SET MAN/AUTO MODE object

SET MAN/AUTO MODE Objects is a CO for changing

the calculation mode for CONTINUOUS CONTROL

object; in AUTO Mode the calculation is carried out

via a proportional algorithm (Δ temperature between

actual temp. and Setpoint Temp) and a integral cor-

rection (Cycle Time ); in MAN mode the output value

control is set by the value send to the object FORCE

VALUE IN MANUAL MODE object.

• If the temperature probe is disconnected or

in short circuit the control action is interrupted and

the controlled actuators are switched o .

• The value of temperature sent on the bus in

case of probe disconnection or short circuit or for out

of range measured value is 0 °C (according to KNX

DPT_Value_Temp 9.001)

TEMPERATURE SENSOR ALARM object

In event of temperature probe failure / out of range

measurement a telegram from 1 bit communication

object - obj #33: “Temperature sensor alarm” - is sent

on the bus with value 1. As soon the temperature sen-

sor works good again a value “0” is transmitted.

To correctly manage the use of internal and/or addi-

tional refers to the following possible con guration

modes:

Loading...

Loading...