VMAC – Vehicle Mounted Air Compressors

Toll Free: 1-800-738-8622 Local: 1-250-740-3200

Fax: 1-250-740-3201

34

6.0 Hydraulic System Data

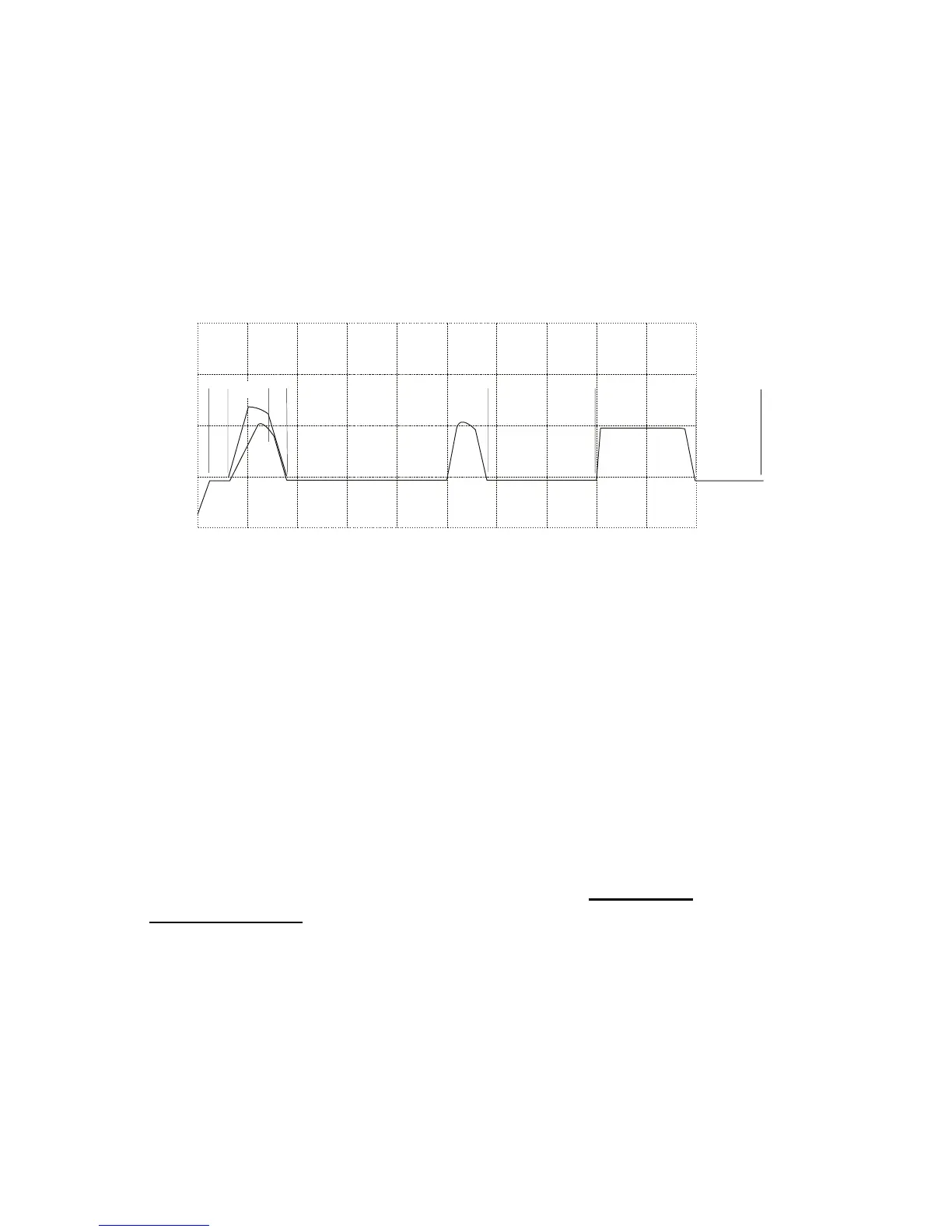

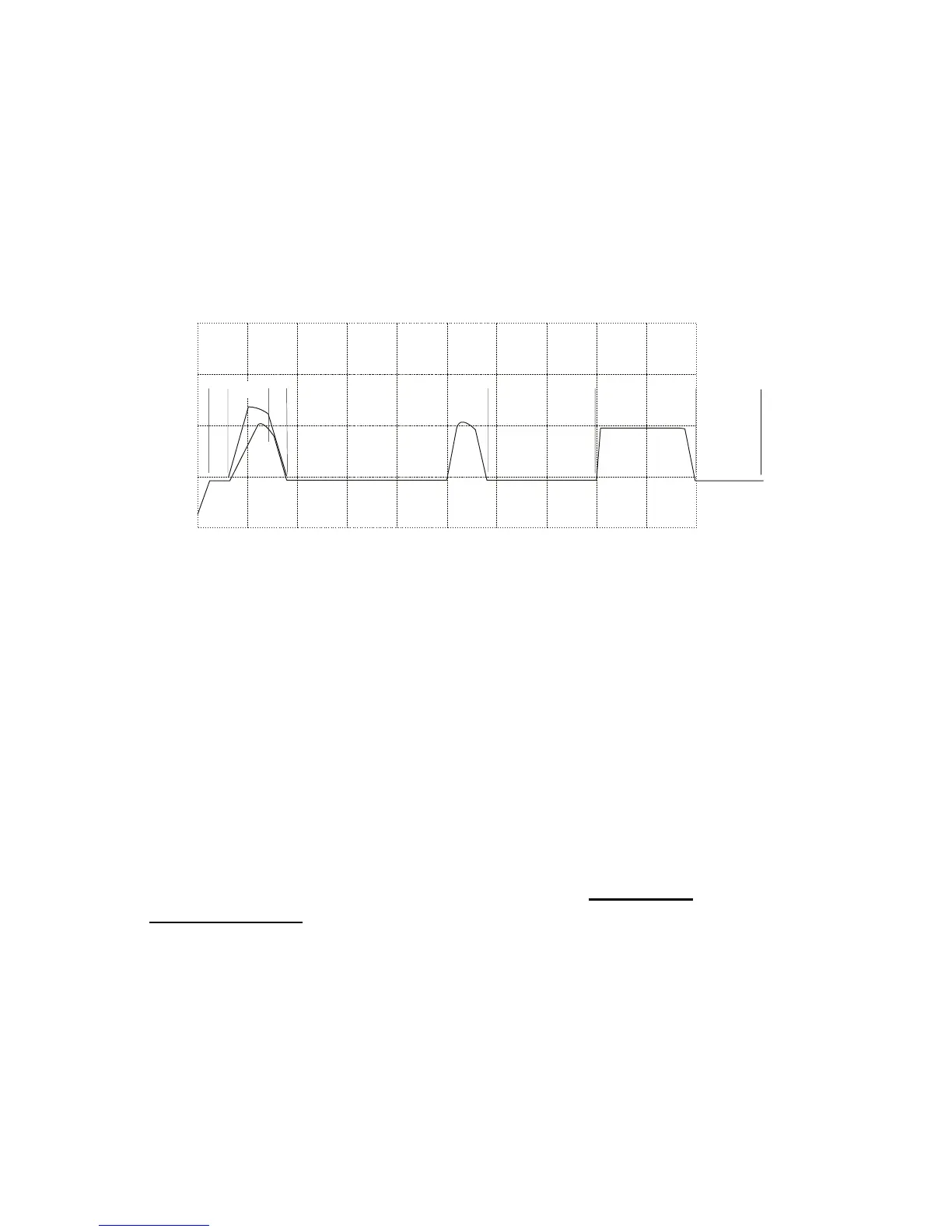

Hydraulic System Pressure will vary considerably during compressor

operation (Figure 20). The system pressure varies between 900 and

2,400 psi during normal operation.

The pump must be rated for 1,900 psi steady operation and 2,600

psi intermittent to allow an additional 200 psi for pressure drop in the

hydraulic lines (external to the PREDATAIR60) during startup with

cold oil.

0 2 4 6 8 10 12 14 16 18 20

3000

2000

1000

Time in minutes

c pressure

1 2 3 4 5 6 7 8

OPERATION

1. Compressor warming up in unloaded state.

2. Compressor filling receiving tank, cold hydraulic fluid.

3. Compressor unloading.

4. No air consumption, compressor in unloaded state.

5. Brief use of compressed air, compressor tops up receiver and unloads.

6. No air consumption, compressor in unloaded state.

7. Sustained heavy air consumption, compressor maintains air pressure

then tops up receiver and unloads.

8. No air consum

ressor in unloaded state.

Figure 20 – Hydraulic System Pressures

6.1 Hydraulic Oil Type

Use a premium quality anti-wear type mineral oil. Do not use

synthetic fluids. Consider the lowest overnight temperature for the

duration of the hydraulic oil in the system at all anticipated vehicle

locations:

• Extreme Cold Climate where temperatures are below -4°F (-

20°C)

• Cold Climate where temperatures are below 32°F (0°C), but not

lower than -4°F (-20°C)

• Temperate Climate where temperatures are above 32° F (0°C)

Loading...

Loading...