Repairing the drive-unit antifouling

coating

The propulsion unit and propellers have an antifoul-

ing coating applied from delivery. Inspect the coating

annually and scrape off any loose coating and apply

a fresh coating. Volvo Penta recommends the coat-

ing “Prop speed

®

“. For instructions on how to apply

the coating, please refer to the instructions that come

with the “Prop speed

®

“.

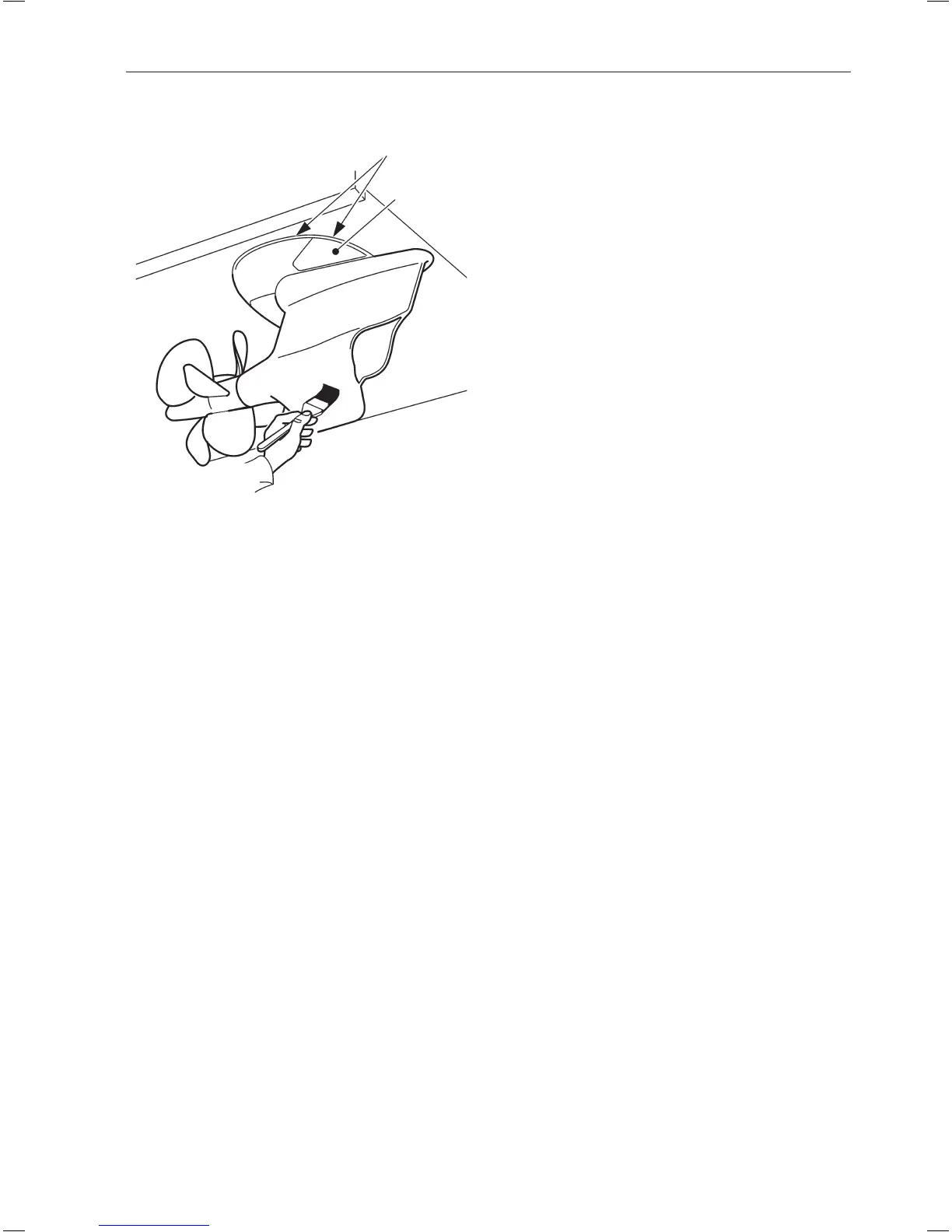

NOTE! Do not apply coating in the grove (A) between

the propulsion unit and the hull or on the exhaust pad

(B).

Wait for the coating to dry before launching the boat.

Painting the underwater hull

All types of paints with anti-fouling properties are

poisonous and cause damage to the marine environ-

ment. Avoid the use of such agents. Most countries

have introduced legislation controlling the use of

anti-fouling agents. Check the legislation that applies

where the boat is to be used.

NOTE! Always abide by these regulations. In many

cases it is completely forbidden to use them on plea-

sure boats, for example in freshwater.

Tin-based agents (TBT) must not be used.

For boats that are relatively easy to get out of the

water we recommend only Teflon treatment combined

with mechanical cleaning several times per season.

For larger craft, this is not practicable. If the boat is

in an area where the water quickly produces fouling,

then anti-fouling paint must probably be used.

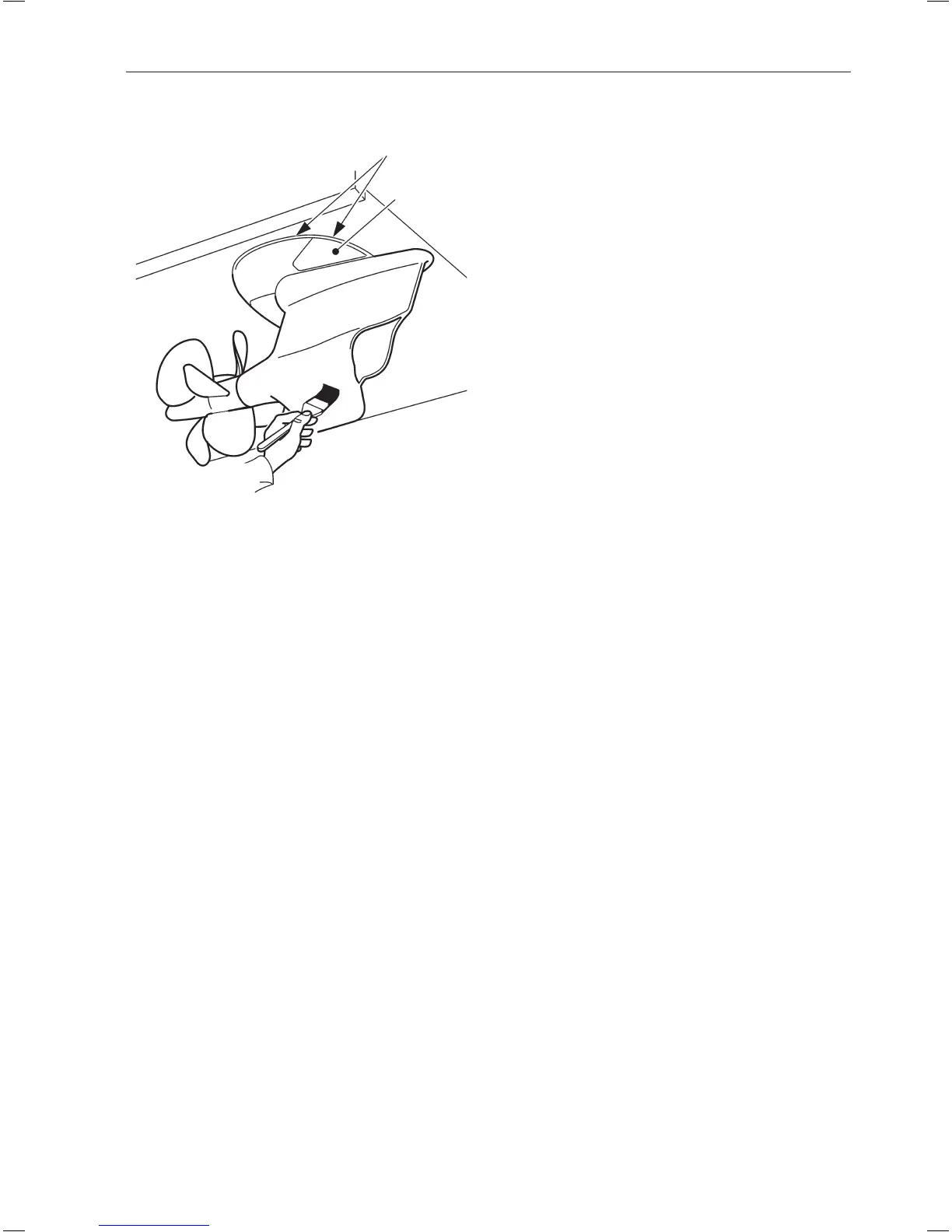

NOTE! Do not paint in the grove (A) between the Pro-

pulsion unit and the hull or on the exhaust pad (B).

Wait for the paint to dry before launching the boat.

Loading...

Loading...