Group 21 Reconditioning

engine

Specifications

TIGHTENING

TORQUES

The tighteni

ng

to

rques

apply

to

oiled screws,

bolts

and

nuts. Degreased {washedl parts

must

be

oiled

before

use.

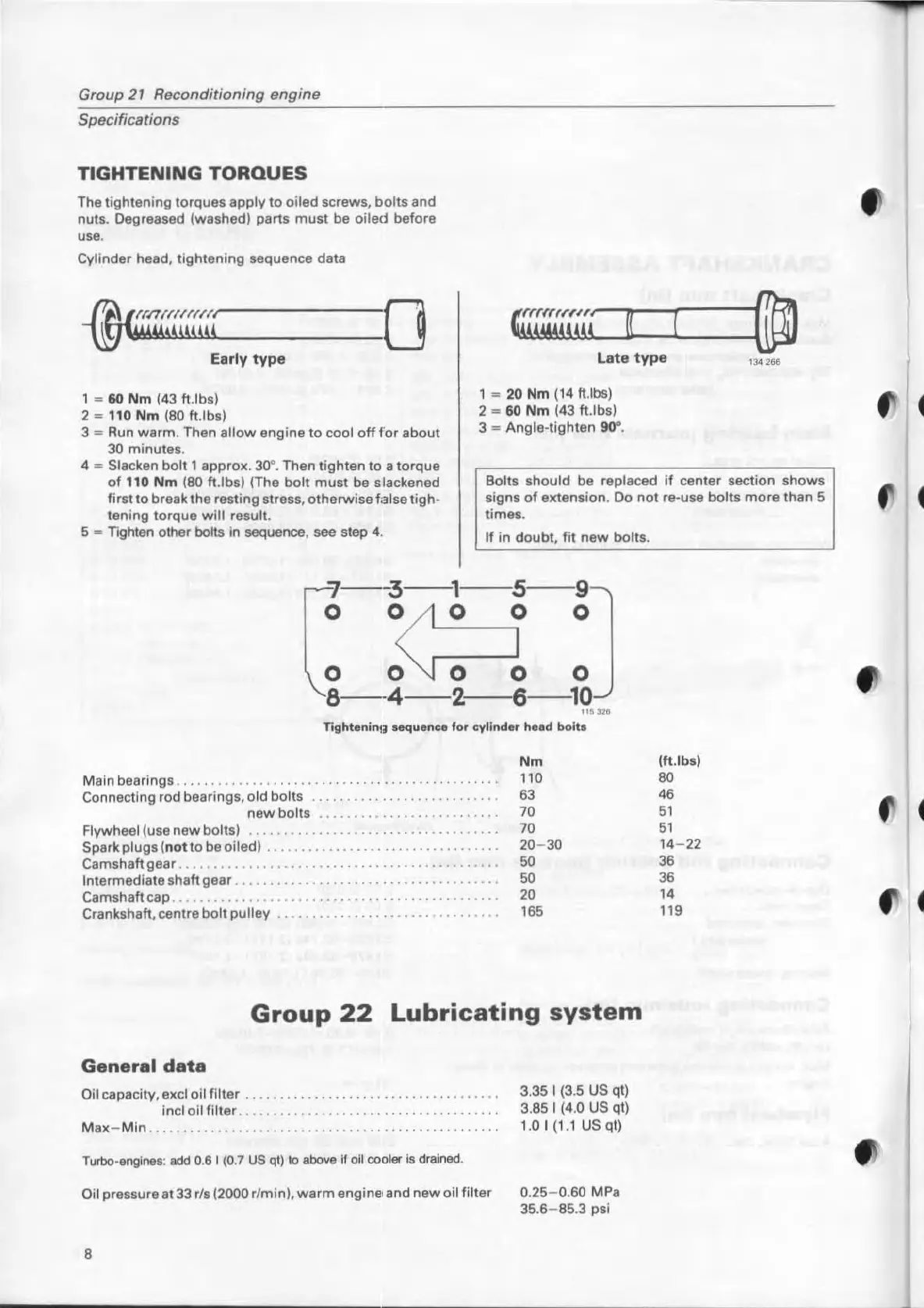

Cylinder head, tightening sequence data

~o

,

~

r<7

~

r'

~

/

~

r

~

I,

~

r

~

,

~

,

_________

O

·W'UJM" l

UlU

ttrrrrrrr

r"j

~

~~I~U~W~!!~!!~.

__

~

ij

~~

_____

~

Early

type

La

te

t

ype

1 -

60

Nm

(43 ft.lbs)

2

'"'

110 Nm (80 fUbs)

3 -

Run

warm

. Then

allowengine

to

cool

off

for

about

30 minutes.

1 -

20 Nm

(14

tUbs)

2

""

60

Nm

(43

tUbs)

3 _ Angle-tighten 90".

4 - SIaeken bolt 1 approx. 30". Then tighten to a

torque

of

110

Nm

(BO

ft.lbs) (The

bolt

must

be slackened

first to break the resting stress,

otherwise

false tig h-

tening

torque

will

result.

Bolts

should be replaced

if

center saction shows

signs

of

extension.

00

not

re-use bolts

more

than 5

times.

5 = rlQhlen other botts

in

sequence, see step 4.

If

in

doubt,

fit

new

bolts.

Main bearings

...

Connecting rod bearings, old bolts

new

bolts

Flywheel

(use new bolts)

Sparkplugs (

no

tto

be oiled)

...

Camshaftgear

...

........

Intermediate shaft gear

..

Camshaftcap

..

.. .......

Crankshaft, centre

bolt

pulley

..

"I

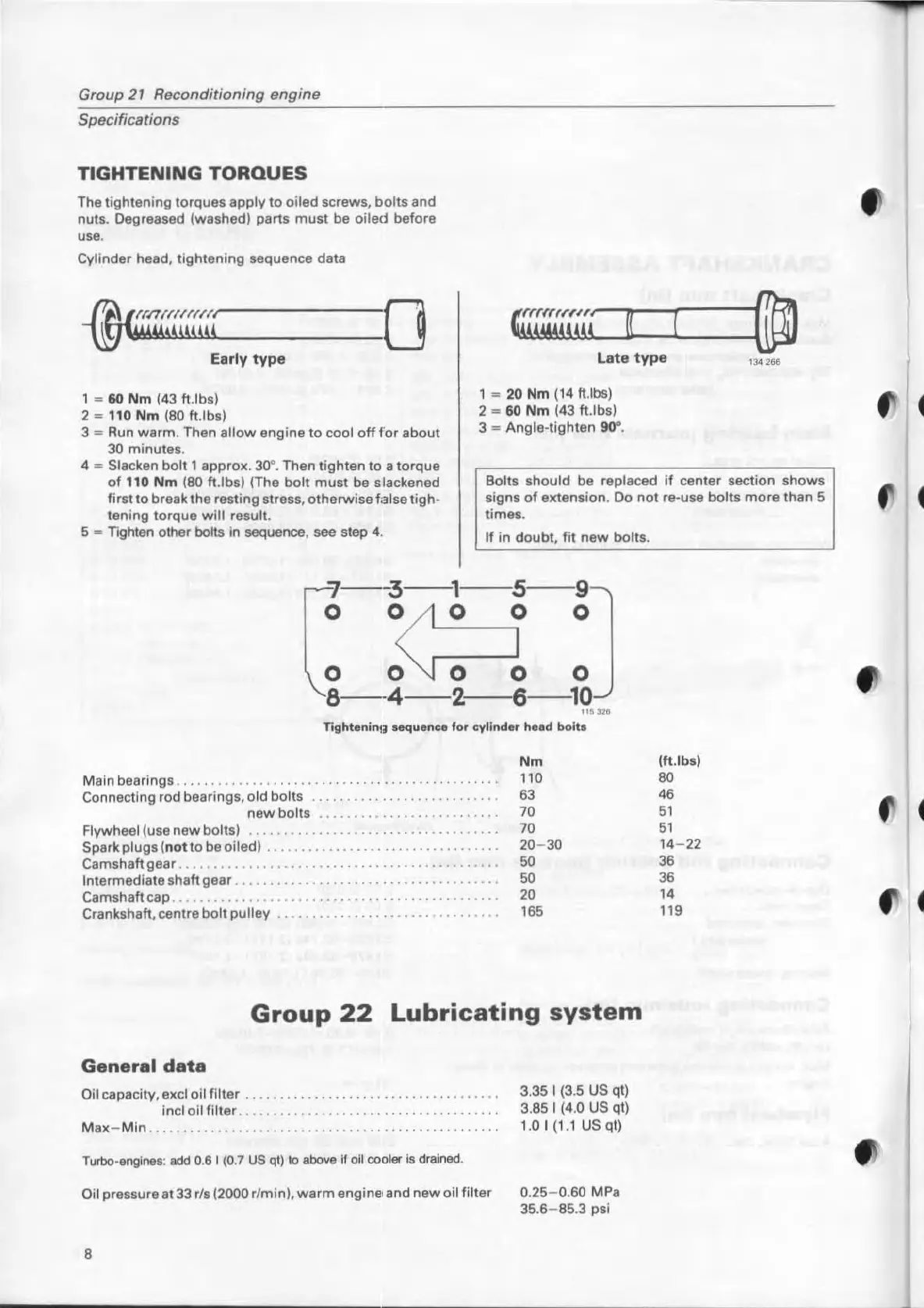

3,--,-

- ·

O O

O O O O O

8-

·

4-2,.--16

-

10

115

U8

T

i

gh

t

8n

i

nt~

Hqu

ence

for

c

ylin

de

r h

e.

d

bolt.

Nm

.. .... ..

11

0

63

70

70

..

.......

20

-

30

50

.

.......

50

20

. .......

..

165

Group

22

Lubricating

system

Gene.al

data

Oil capacity, exel oil filter

..

incl oil filter.

Max- Min

..........

.

Turbo·engines: add 0.6 I (0.7

US

qt)

to

above

il

011

000191'

is

drained

.

Oil

pressure at

33

rIs (2000 rImin),

warm

engine! and new oil filter

8

3.35 I

(3

.5

US

qt)

3.85 I (4.0

US

qt)

1.0 I

(1

.1

US

qt)

0.25- 0.

60

MPa

35.6- 85.3 psj

(

ft.lb

s)

80

46

51

51

14- 22

36

36

14

119

Loading...

Loading...