Group

2J

Reconditioning

engine

Cyfinder head, cfeaning, inspection

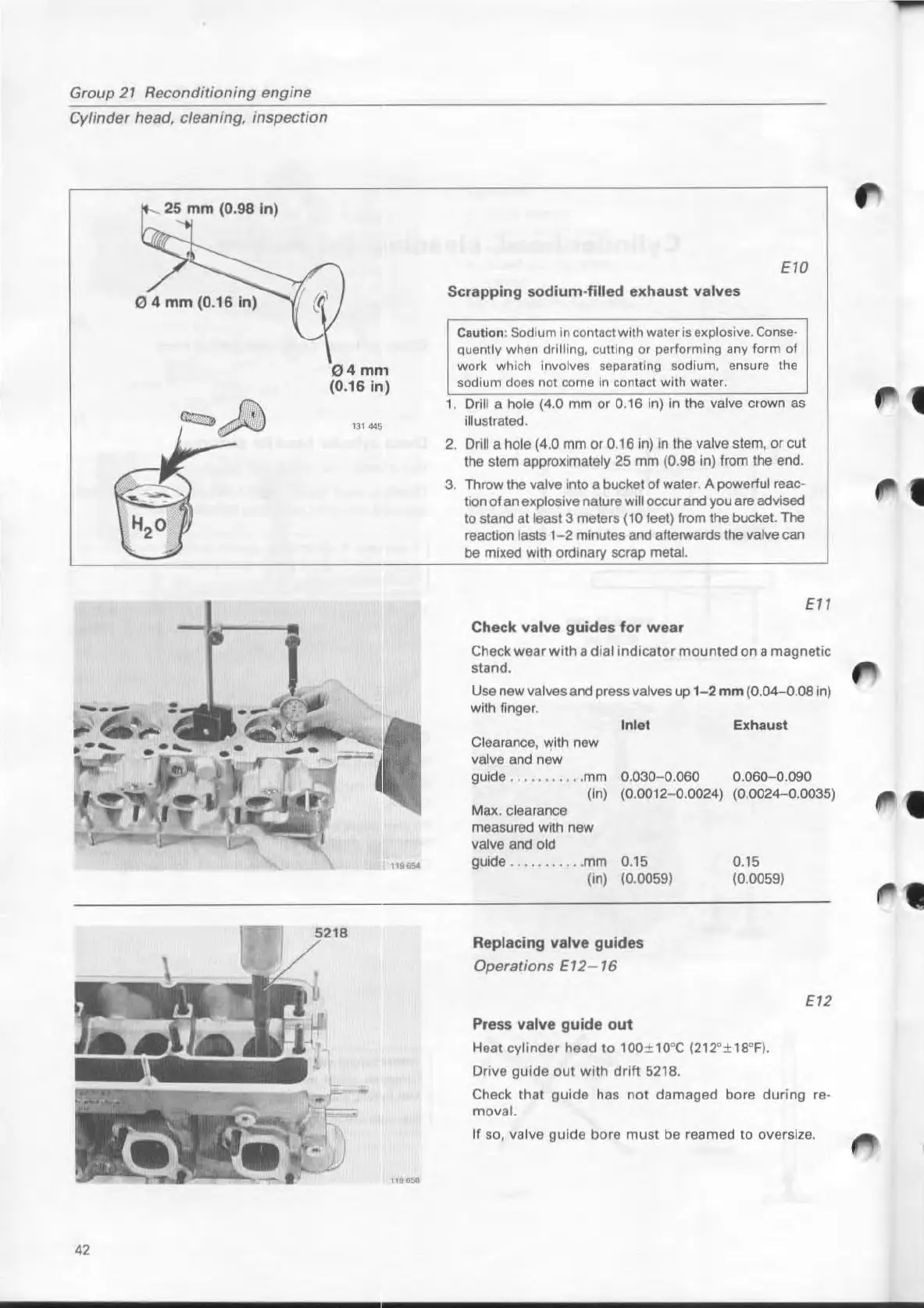

25

mm

(0.

98

in)

42

(. ,

,

04mnl

(0.16

in)

131

.... 5

E10

Scrapping

sodium·filled

exhaust

valves

Caution;

Sodlum

in

contactwith

water

is explosive. Conse-

quently

when

drilling,

cutting

or

performing

any

form

of

work

which involves separating

sodium,

ensure the

sodium

does

not

come in contact

with

water,

1,

Drill a hote (4.0

mm

or 0.

16

In)

In

the valva Clown as

illustrated.

2.

Drill a hole (4.0 mm

or

0.16 in) in Ihe valve stem,

or

cul

lhe slem approximately

25

mm (0.98 in) from the end.

3.

Throw

the

valve inlo a buckel

of

waler. A powerful reac-

tion

of

an explosive nature will occur and you are advised

to stand at

least3

meters (10 feet) from the bucket. The

reaclion lasts

1-2

minules and afterwards the valve

can

be

mixed with ordinary scrap melal.

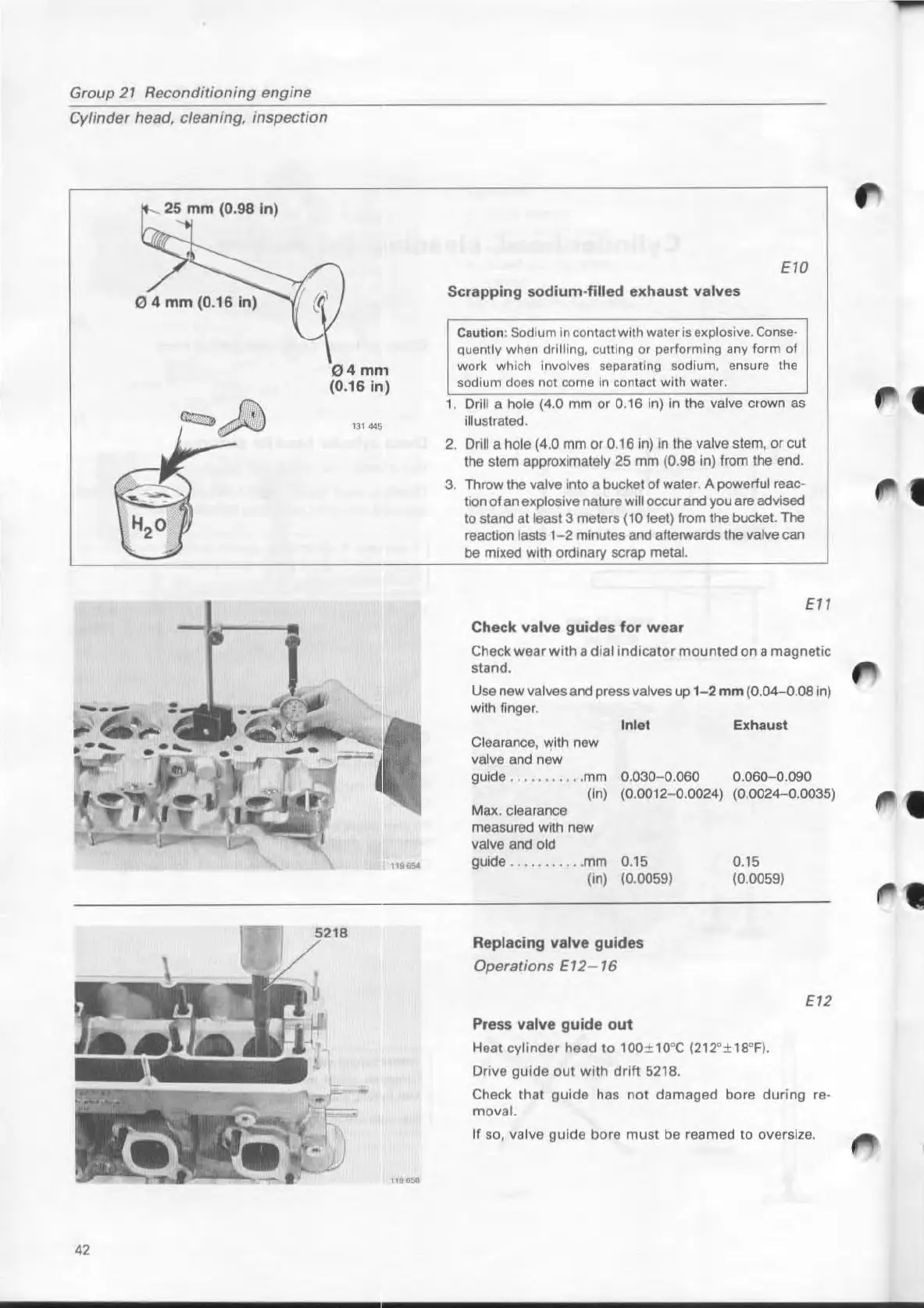

Check valve

guides

for

wear

El1

Checkwearwith

a diat

indicator

mounted

on

a

magnetic

stand.

Use new valves

and

press valves up

1-2

mm (0.04-0.08

in)

with finger.

Clearance,

"Vith

new

valve and new

Inlet Exhaust

guide

...........

mm

0.030-0.060 0.060-0.090

(In) (0.0012-0.0024) (0.0024-0.0035)

Max. clearance

measured with new

valve and

old

guide

...........

mm

0.15

(in) (0.0059)

Replacing valve

guides

Operations

E12-16

Press valve

guide

out

0.15

(0.0059)

Heat

cylinder

head

to

100±

100C

(212°±1SOF).

Drive

guide

out

with

drift

5218.

E12

Check

that

guide

has

not

damaged

bore

during

re-

moval.

If so,

valve

guide

bore

must

be

rea

med

to

oversize.

1

1

,

Loading...

Loading...