Group

21

Reconditioning engine

C/eaning, checking

,

...

"

34

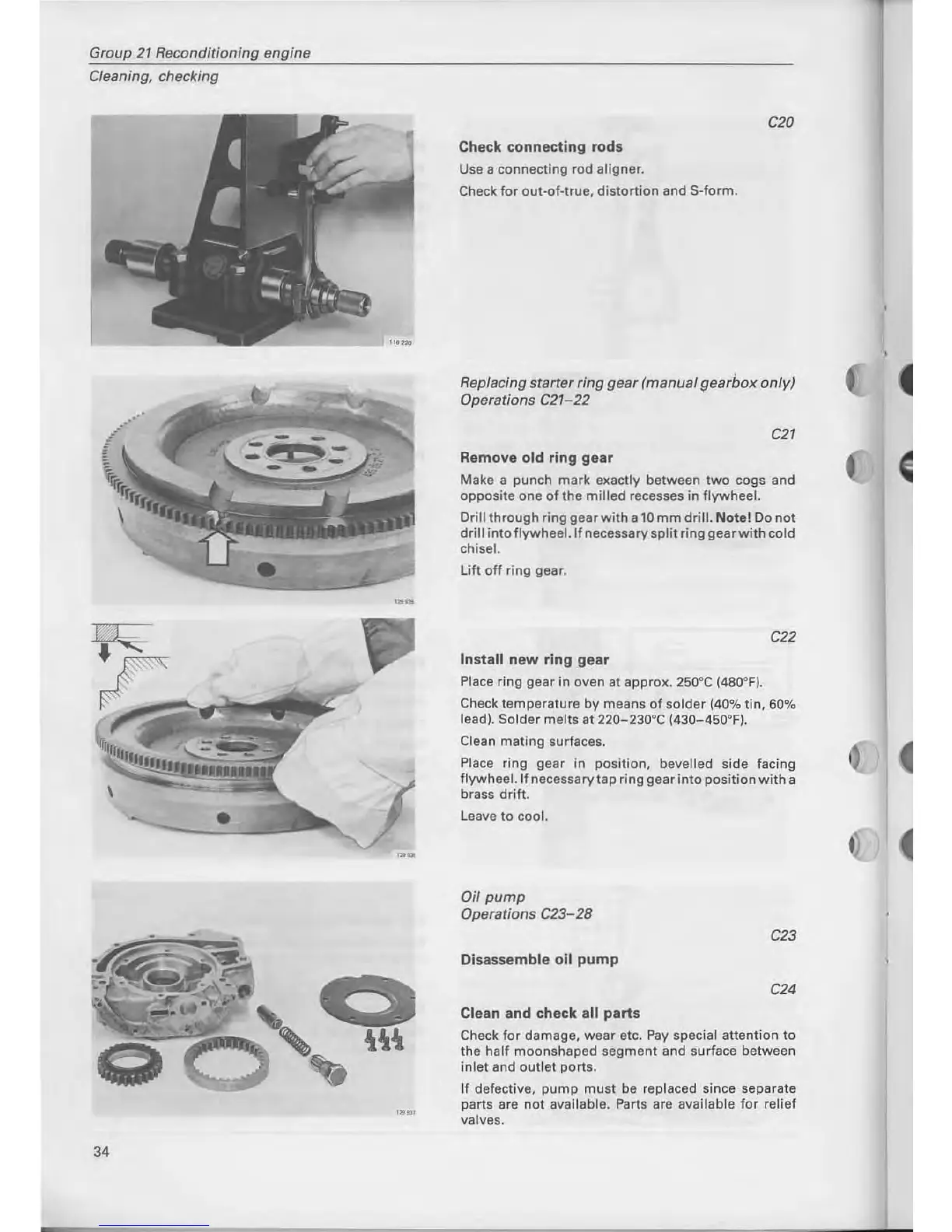

Check

connecting

rods

Use a connecting rad aligner.

Check

for out-of-true,

distortion

and S-form.

C20

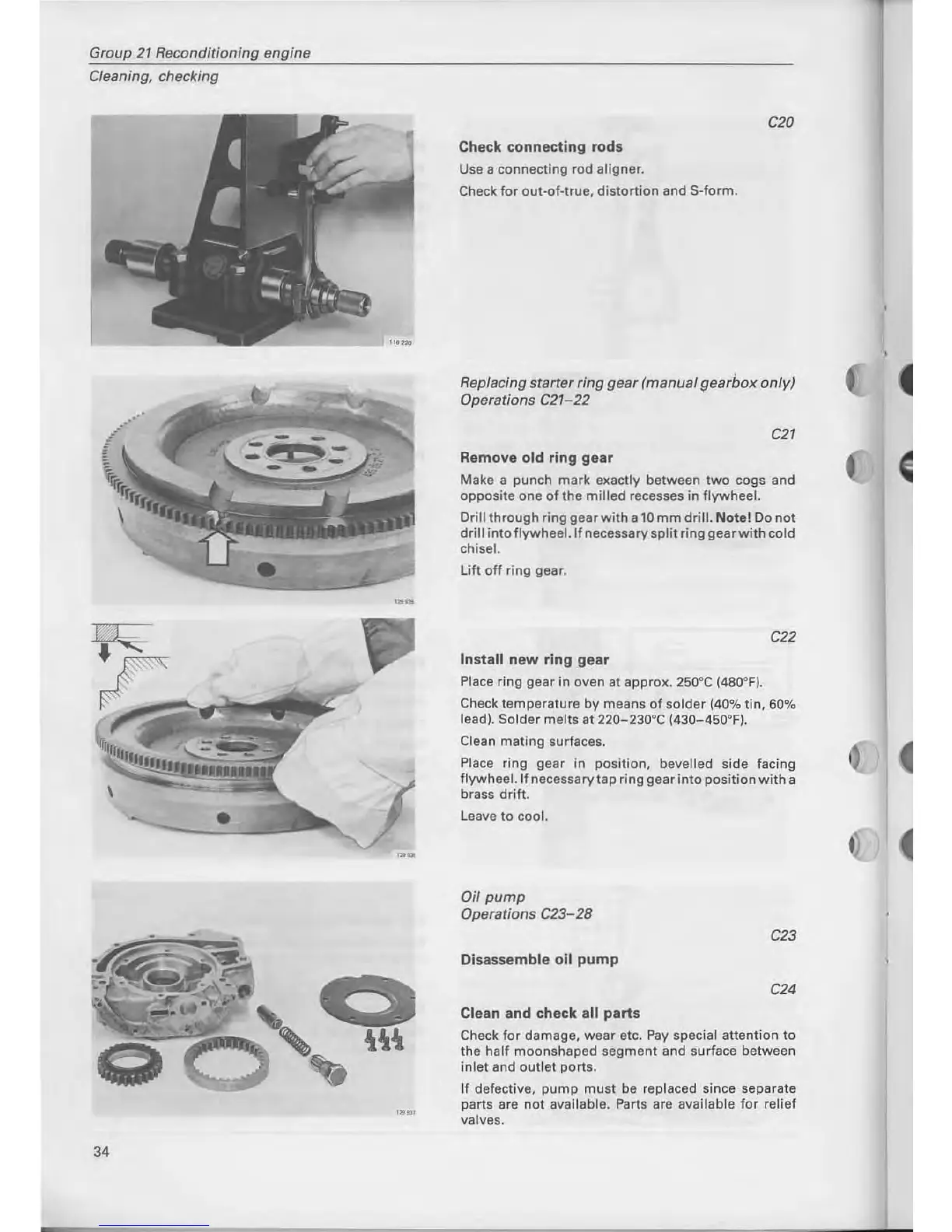

Replacing starter ring

gear

(manua/

gearbox

on/v)

Operations C21-22

C21

Remove

old

ring

gear

Make a punch mark exactly between

two

cogs and

opposite one

of

the

milled

recesses

in

flywheel.

Drill

through

ring

gearwith

a

10

mm

drill.

Notel

Do

not

drill

inta

flywhe

el.lf

necessarysplit ring

gearwith

cold

chisel.

Lift

off

ring gear.

C22

Install

new

ring

gear

Place ring gear in aven at approx. 250

"C

(480°F).

Check

temperature by means

of

solder (40% tin,

60%

lead). Solder melts at 220-230"C (430-450"F).

Clean

mating

surfaces.

Place ring gear in position, bevelled side facing

flywheel.lf

necessarytap ring gear

inta

position

with

a

brass

drift.

Leave

to

cool.

Oil

pump

Operations

C23-28

Disassemble

oil

pump

Clean

and

check

all

parts

C23

C24

Check for damage, wear etc.

Pay

special attention

to

the half moonshaped segment and surface between

inlet and

autlet

ports.

If

defective,

pump

must be replaced since separate

parts are not

available. Parts are available for relief

valves.

,

Loading...

Loading...