Operating techniques

Scarifier and ripper operation 143

Scarifier and ripper operation

n When operating close to electrical lines, underground cables,

water mains or gas lines, contact the responsible authority

and request assistance.

n When scarifying or ripping across a slope, keep the mold-

board parallel with the front axle, centered to the frame and

lowered close to the ground to provide protection against roll-

ing over.

A Volvo scarifier or ripper is useful for breaking up hard surfaces

such as asphalt, rocky subgrade and ice to ease grading.

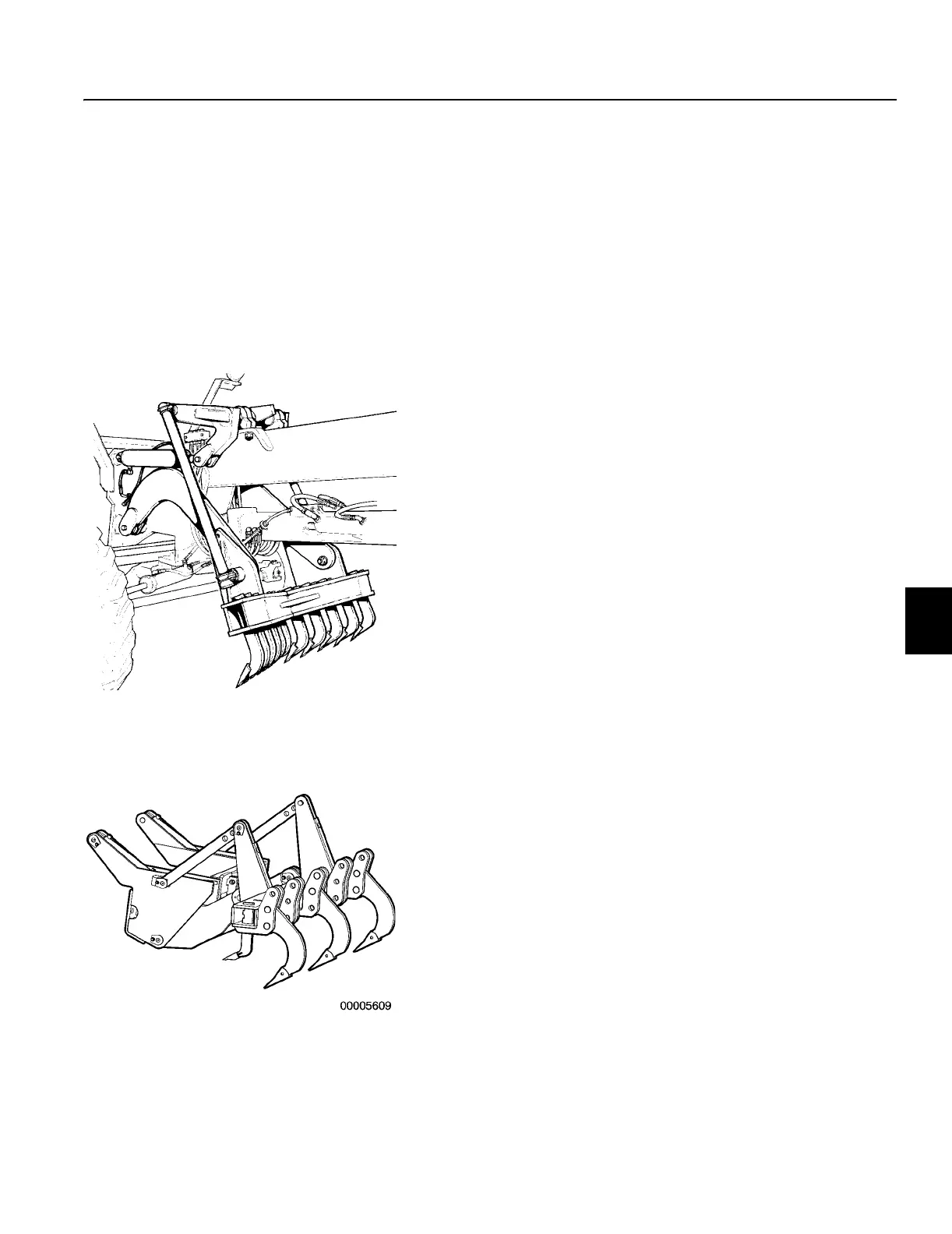

Scarifier

A scarifier is mounted either on the front of the machine or behind

the front wheels and is hydraulically operated from inside the cab.

Refer to Control lever for scarifier, ripper or windrow eliminator

page 68. The mid-mounted scarifier can be used with other front

mounted attachments.

The scarifier is equipped with up to eleven teeth that are adjust-

able and replaceable. Use the scarifier to break up surfaces that

are too hard to cut with the moldboard. For especially hard surfac-

es, reduce the number of teeth. Always lower the scarifier teeth

into the material slowly while the grader is moving at a low speed.

Do not skid the teeth along hard surfaces such as large rocks or

pavement. Do not use the scarifier when turning or articulating.

This places side loads on the scarifier teeth and may result in

equipment damage.

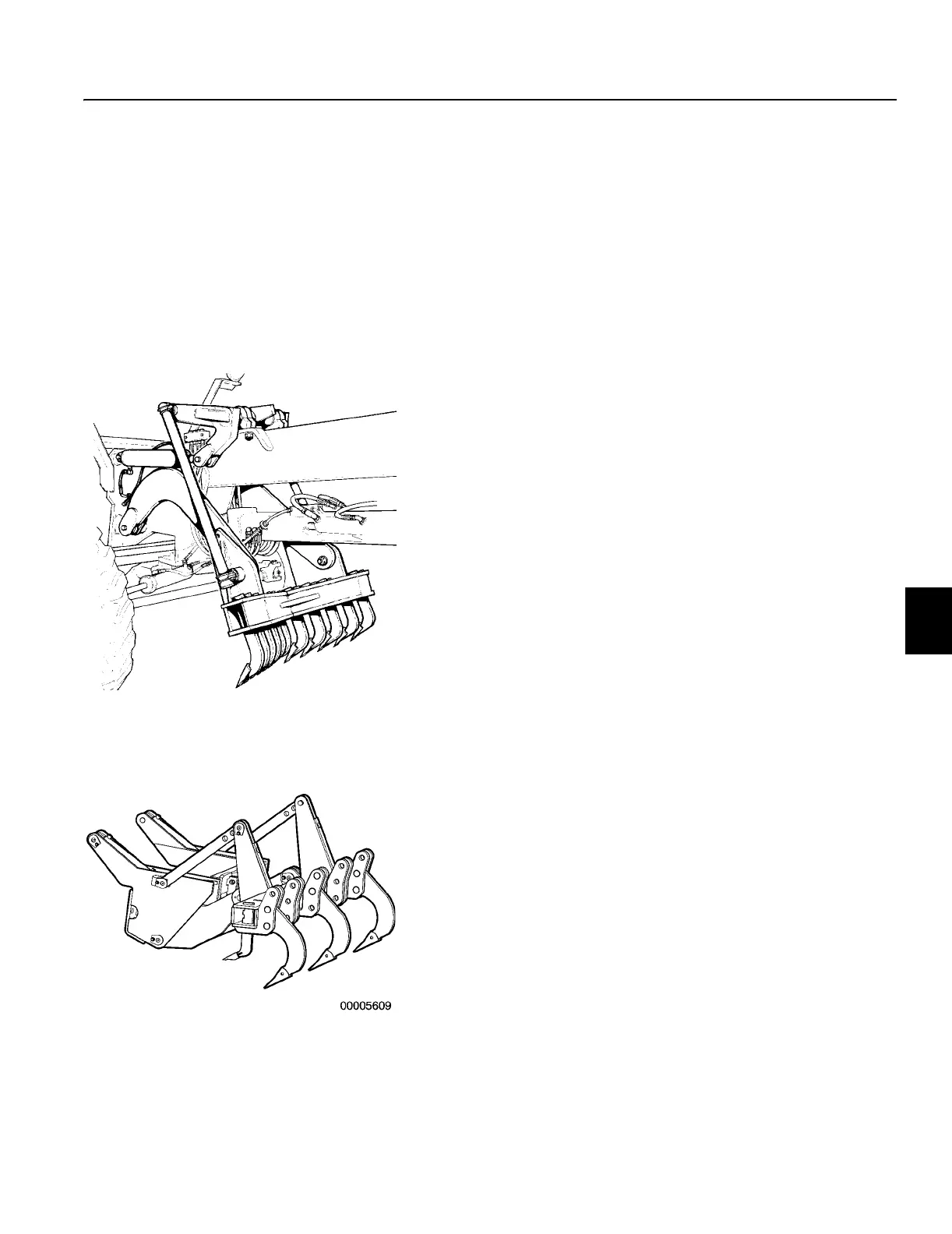

Ripper

The ripper is very useful for dislodging large rocks and tree

stumps, and breaking up asphalt pavement. The ripper can be

equipped with five ripper teeth or nine scarifier teeth. The ripper is

hydraulically operated from inside the cab. Refer to Auxiliary hy-

draulic controls page 70.

When using the ripper, lower the teeth into the ground with the

grader in motion. If the rear wheels lose traction, raise the ripper

until the wheels regain traction. For especially hard surfaces, re-

duce the number of teeth. To break old pavement, lower the teeth

under the pavement and raise the ripper. Avoid the use of the rip-

per when turning, this reduces wear on equipment.

Loading...

Loading...