82

PXM

P_02682

OPERATING AND ASSEMBLY MANUAL

VERSION 08/2015 ORDER NUMBER DOC2350372

8.2.6 CLEANING/PAINT CHANGE ON THE PXM WITH ULTRASONIC SIEVE

Notes for the paint change sequence:

The ultrasound sieve can be cleaned either manually or using existing cleaning components.

Three steps are planned:

Coarse cleaning using the internal cleaning program of the IP 5000 fresh powder

pump. The screen frame can remain installed.

Main cleaning with blowout device and compressed air pulses (see Cleaning

Parameters, Chapter 6.9.2). The sieve frame must be replaced with a dummy frame to

avoid damage to the sieve fabric.

Perform a manual nal cleaning of the individual components.

1. Plug the outlet hose to the park position.

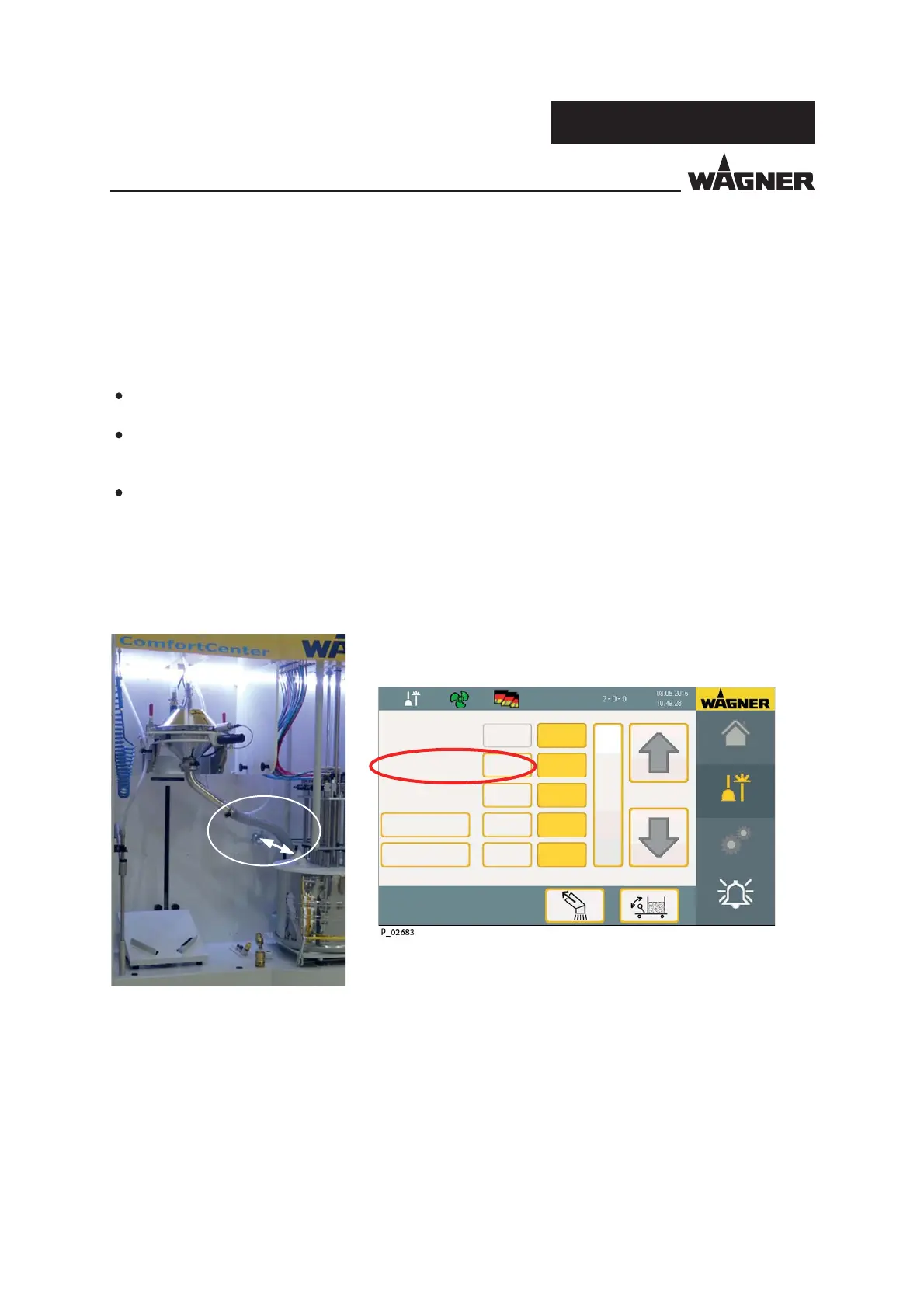

2. Clean IP 5000 internally.

Home page

Cleaning

Settings

Alarm

Worker

Injector blow out On

On

O

O

End

On O FP pump intensive

On O

On O FP pump standard

RP hose

US Sieve

Loading...

Loading...