10

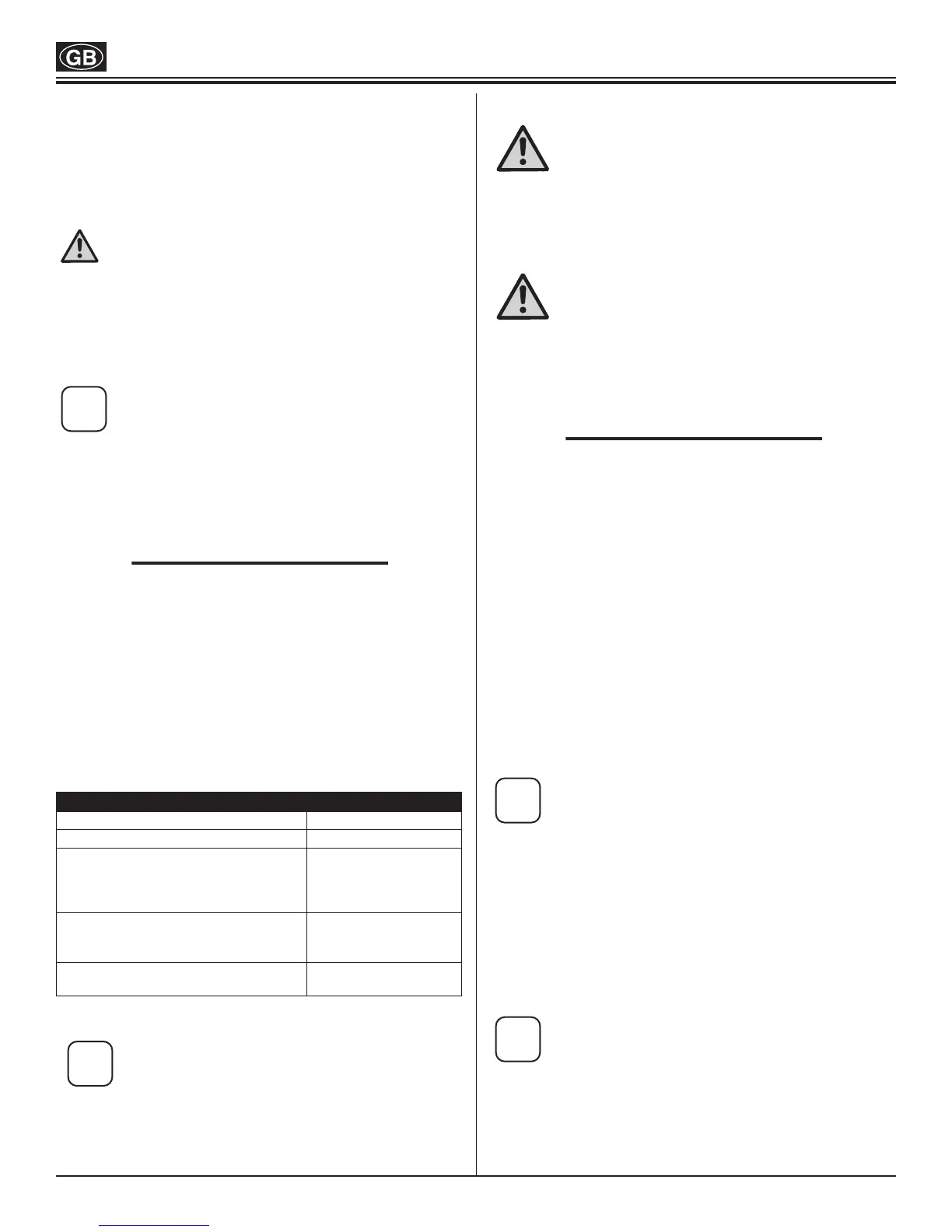

Wagner Project Pro 117 - 0418B

Assembly

Figure 2 - Attaching the Hose

Make sure that the pump is switched o (position O) and

the spray device is disconnected from the power supply.

1. Thread the high pressure hose to the spray hose port. Tighten

with an adjustable wrench.

2. Thread the other end of the hose to the spray gun. Grip the

spray gun with an adjustable wrench on the handle, and

tighten the hose nut with the other.

The spray tip should not be attached until after the

sprayer and spray hose have been purged and primed.

Figure 3 - Attaching the Suction Set

1. Remove cap from inlet valve (a). Thread the suction tube onto

the inlet valve and tighten rmly by hand. Be sure that the

threads are straight so that the tting turns freely.

2. Push the return hose into the return connection piece.

Before You Begin

Preparation of the Coating Material

UsingProjectPro117interiorwallpaints,varnishesandglazescan

be applied by spraying without diluting them, or by diluting them

slightly.

Detailed information is available in the technical data sheet of the

manufacturer ( Internet download).

1. Stirthematerialthoroughlyanddiluteitinthecontaineras

per the recommended dilution (an agitator is recommended

for stirring).

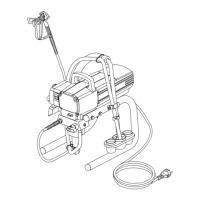

Thinning recommendation

Sprayed material

Glazes undiluted

Wood preservatives containing

solvents or based on water, mordants,

oils, disinfection agents, plant

protective agents

undiluted

Paints containing solvents and

water-soluble paints, primers, vehicle

coating paints, thick-lm glazes

dilute by 5 - 10%

Interior wall paint (dispersions and latex

paint)

dilute by 0 - 10%

2. Do a test spray (e.g. on to a piece of cardboard).

If the paint sprays evenly, as shown in g. 11 A, all the

setting must be correct.

If the paint looks stripy after spraying, as shown in g.

11 B, gradually increase the pressure, or dilute more in

5% steps.

Figure 4 - Locking the Spray Gun

Always lock the trigger o when attaching the spray

tip or when the spray gun is not in use.

1. The gun is secured when the trigger lock is at a 90° angle

(perpendicular) to the trigger in either direction.

Figure 5 - Pressure Relief Procedure

Be sure to follow the Pressure Relief Procedure

when shutting the unit o for any purpose. This

procedure is used to relieve pressure from the spray

hose.

1. Lockthesprayguno.FliptheON/OFFswitchtotheOFF

position.

2. TurnthePRIME/SPRAYknobtoPRIME.

3. Unlockthespraygunandtriggerspraygunintothesideof

thematerialbucket.Lockthespraygun.

Priming

Figure 6 - Preparing to Prime

1. Sprayalittleoiloutoftheprovidedaskintothemarked

opening(tip:tiltthedeviceback).Lighthouseholdoilcanbe

substituted if necessary.

2. FullyinserttheQuicko™valvetomakesuretheinletballis

free.

Figure 7 - Priming the Sprayer

1. Place a full container of spraying material underneath the

suctiontube(a).Securethereturntube(b)intoawaste

container.

2. SlidethePressureTrac™tomaximumpressure(+).

3. TurnthePRIME/SPRAYknobtoPRIME.

4. PluginthesprayerandmovetheON/OFFswitchtotheON(l)

position.

The unit will begin to draw material up the suction

tube, into the pump, and out the return tube. Let the

unit cycle long enough to remove test uid from the

pump, or until spray material is coming from the return

tube.

5. SwitchthepumpOFF(O).Removethereturntubefromthe

waste container and place it in its operating position above

thecontainerofsprayingmaterial.Usethemetalcliptobind

the two hoses together.

Figure 8 - Priming the Spray Hose

1. UnlockthespraygunandturnthePRIME/SPRAYknobto

PRIME.

The spray tip should not be attached to your spray gun

when purging your spray hose.

2. PULLthetriggerandaimthespraygunatthesidewallofa

waste container. If using oil-based materials, the spray gun

must be grounded while purging (see warning below).

Field of application

Coating of interior walls as well as small and medium-sized objects

outdoors (e.g. garden fences, garage doors, etc.).

Loading...

Loading...