Maintenance Instructions LUBRICATION/CLEANING

49

Air Restriction Gauge Location

Clean and inspect the paper element after every

100 hours of service and replace the element

yearly or after six (6) cleanings (or when dirty or

damaged). More frequent cleaning may be required

when operating in extremely dusty conditions as

indicated by a loss of engine power. Service the air

cleaner as follows:

1. Release the top and bottom cover latches and

remove the air cleaner cover. Wash the cover

and Vacuator™ valve. Check that these com-

ponents are in good condition. The Vacuator™

valve is subject to wear and deterioration and

should be replaced yearly or when damaged.

The lips of the valve should close and fit

together; any cracks, deformation, or wear in the

valve is cause for replacement.

2. Remove the filter element by pulling it out of the

canister. There will be some initial resistance as

the filter seal breaks loose and slides off of the

outlet tube. Gently move the end of the filter up

and down and side to side or twist to loosen the

seal. Use gentle action to minimize the amount

of dust dislodged as the filter is removed.

3. Clean the filter element using low pressure

compressed air [less than 100 PSI (689 kPa)].

Blow out the filter from the interior of the element

while turning the element.

NOTE: Washing the element in water or clean-

ing solution is not recommended. Replace the

element if it does not clean up with compressed

air.

4. Use a bright light inside the element to inspect

for damage. Check the element very carefully

for pin holes or other damage that will allow

dirt to leak through the paper media. Replace

element if necessary.

5. Check the condition and resilience of the radial

sealing surface (inside of the open end) of the fil-

ter. Replace the filter if any cracks, tears, or

other damage to the sealing surface are noted.

6. Use a clean, damp cloth and wipe the interior of

the air cleaner canister clean. Use special care

to clean both the inside and outside surfaces

of the outlet tube.

IMPORTANT: Any dust left on the inside of the

outlet tube will go into the engine and cause

wear.

7. Check the outside surface of the outlet tube for

smoothness and cleanness (this is the sealing

surface).

8. Insert and seat the filter element carefully into

the canister, applying pressure at the outer rim

of the filter; not at the flexible center. Make sure

the filter element is completely in place before

installing the cover.

IMPORTANT: DO NOT use the cover latches

to force the filter into the canister -- the cover

should fit on with no extra force.

NOTE: DO NOT use petroleum based lubri-

cants on the sealing surfaces of the filter; use tal-

cum powder or dry silicone lubricants if required

for filter installation.

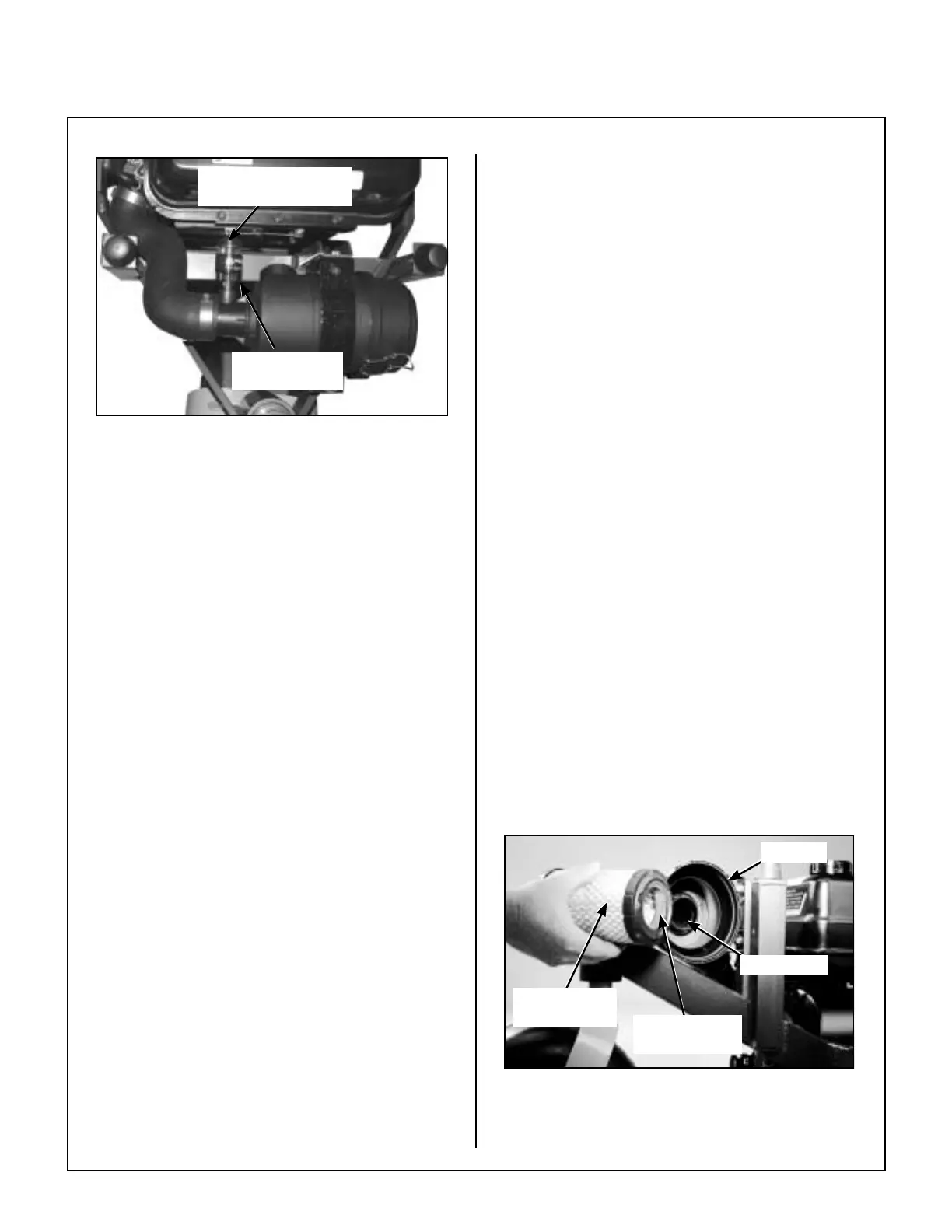

Air Filter Element Replacement

Air Restriction

Gauge

Push Button to Reset

Indicator After Service

Radial Sealing

Surface

Radialseal™

Filter Element

Outlet Tube

Canister

Loading...

Loading...