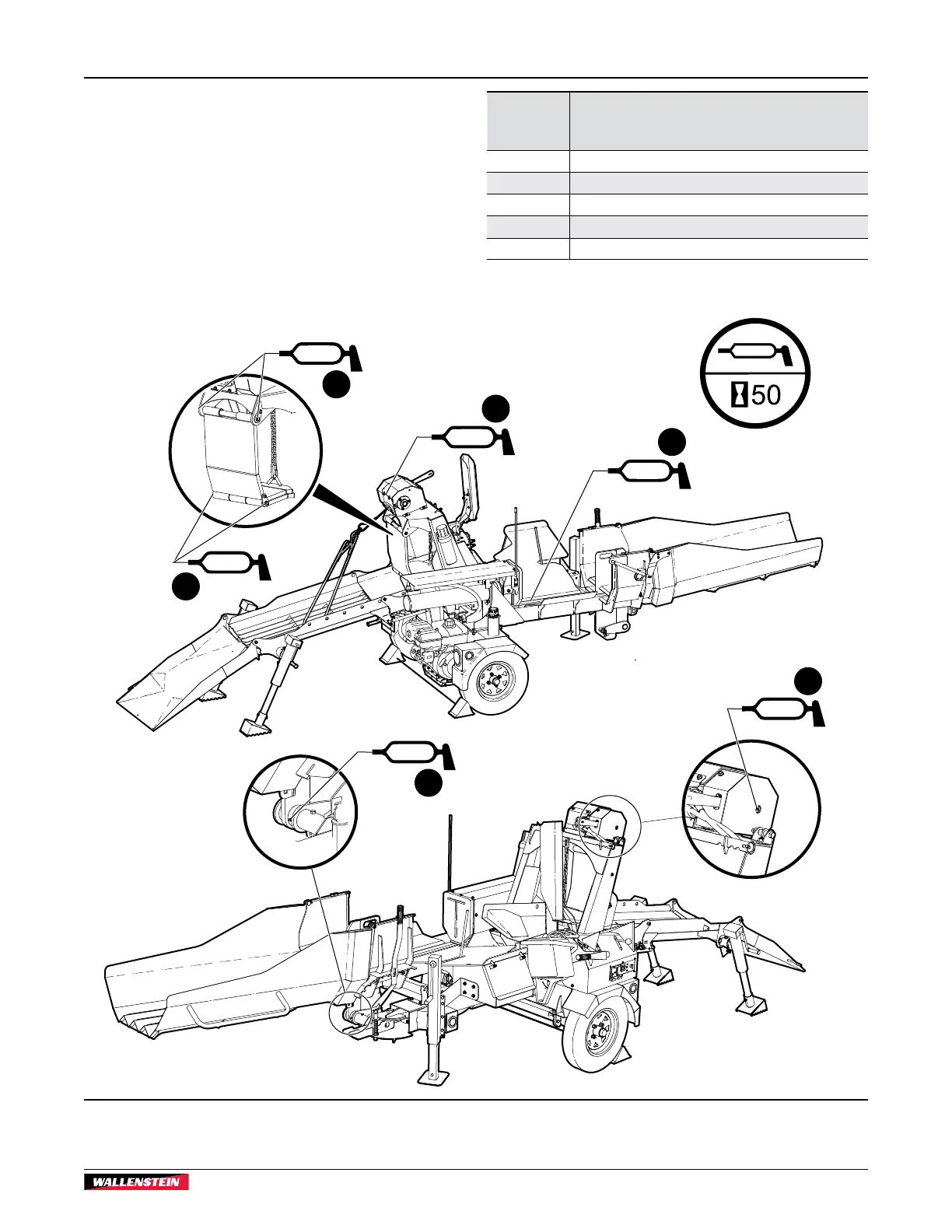

9.4 Grease Points

• Use a hand-held grease gun for all greasing.

• Wipe each grease fitting with a clean cloth before greasing

to avoid injecting dirt and grit.

• Replace or repair broken fittings immediately.

• If a fitting does not take grease, remove and clean the

fitting thoroughly. Also, clean the lubricant passageway. If

required, replace the fitting.

Location

Grease Points

– Every 50 hours or annually

1 Lower RH and LH side of the log stabilizer

2 Upper RH and LH side of the log stabilizer

3 Winch (two locations)

4 Push block frame slide

5 Wedge height adjustment-arm bushing

Fig. 54 – Grease points

01838

1

1

1

2

2

1

2

3

4

5

1

3

WP845 / WP875

Trailer Firewood Processor

Service and Maintenance

59

Loading...

Loading...