10. Troubleshooting

WARNING!

Before troubleshooting, read and understand the

Service and Maintenance Safety on page 56.

Set the machine to a safe condition.

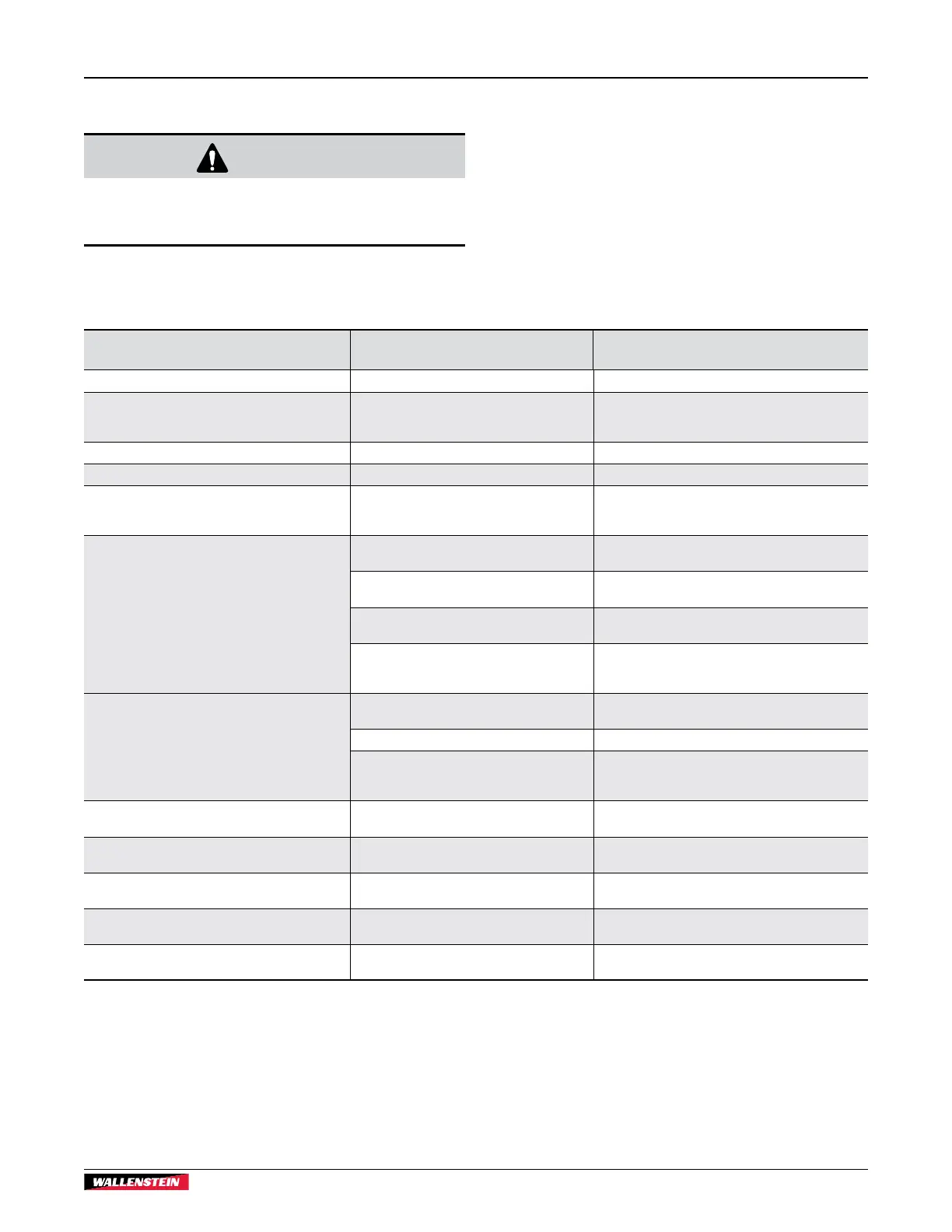

The following table lists some of the problems that you may

encounter and provides possible causes and solutions.

If you encounter a problem that is difficult to solve, even after

reading this information, please contact your local dealer, the

distributor, or Wallenstein Equipment. Before you call, please

have the serial number for your product handy.

To find the serial number on your machine, see Serial Number

Location on page 5.

For engine troubleshooting, see the engine manufacturer's

manual.

Problem Possible cause Solution

Engine is difficult to start or performance is reduced. Engine fuel. Not all fuel is the same. Change the fuel provider or brand.

Winch motor does not move. Rope is jammed. Disengage the winch gear, pull the rope out, and then

carefully guide the rope, while it retracts onto the spool

under load.

Winch rope does not pull out. Winch gear is engaged. Disengage the winch gear.

Winch rope does not retract. Winch gear is disengaged. Engage the winch gear.

Cylinder rod moves slowly or does not move. Wood is jammed around the wedge. Set the machine to a safe condition, and then remove

the wood. For instructions, see Safe Condition on page

9.

Cylinder rod or winch motor moves slowly or does

not move.

No hydraulic fluid pressure because the fluid

filter is plugged.

Change the hydraulic fluid filter. For instructions, see

Change the Hydraulic Fluid and Filter on page 60.

No hydraulic fluid pressure because the

hydraulic fluid is low.

Add hydraulic fluid. For instructions, see Add Hydraulic

Fluid to the Reservoir on page 31.

Low hydraulic pressure. The relief setting may

be low.

Contact a technician.

Low engine speed. Make sure the choke is Closed and the throttle is set

to Fast. For information, see Engine Control Panel on

page 20.

Control lever does not go to neutral after the cylinder

rod is fully advanced or retracted.

Detent is set too tight. Contact a technician. The valve detent requires

adjustment.

Hydraulic fluid is too cold. Wait for the machine to warm up.

Hydraulic fluid is old or contaminated. Change the hydraulic fluid and filter. For instructions,

see Change the Hydraulic Fluid and Filter on page

60.

Control lever goes to neutral before the cylinder rod is

fully advanced or retracted.

Detent is set too loose. Contact a technician. The valve detent requires

adjustment.

Control lever does not go to neutral when released. Control is damaged. Call a technician. The control requires service or

replacement.

Cylinder stops on contact with wood. Second pump stage is not functioning. Call a technician. The pump requires service or

replacement.

Hydraulic hose leak. Hose is worn or damaged or a fitting is not

secure.

Replace the hose or secure the fitting. If required,

replace the fitting.

Cylinder is leaking. Seals are worn. Call a technician. The cylinder requires service or

replacement.

WP845 / WP875

Trailer Firewood Processor

Troubleshooting

63

Loading...

Loading...