11.4 Wheel Lug Nut Torque

CAUTION!

Loose wheel lug nuts can result in broken

studs, risking the wheel coming o the

axle hub. Keep lug nuts torqued to proper

specication.

Maintaining proper wheel lug torque on your trailer axle

is an extremely important safety measure. Always use a

properly calibrated torque wrench.

Torque wheel lug nuts before first road use and after each

wheel removal. Check and re-torque after the first 10 mi

(16 km), 25 mi (40 km), and again at 50 mi (80 km).

Check periodically thereafter.

• Start all lugs by hand to prevent cross threading.

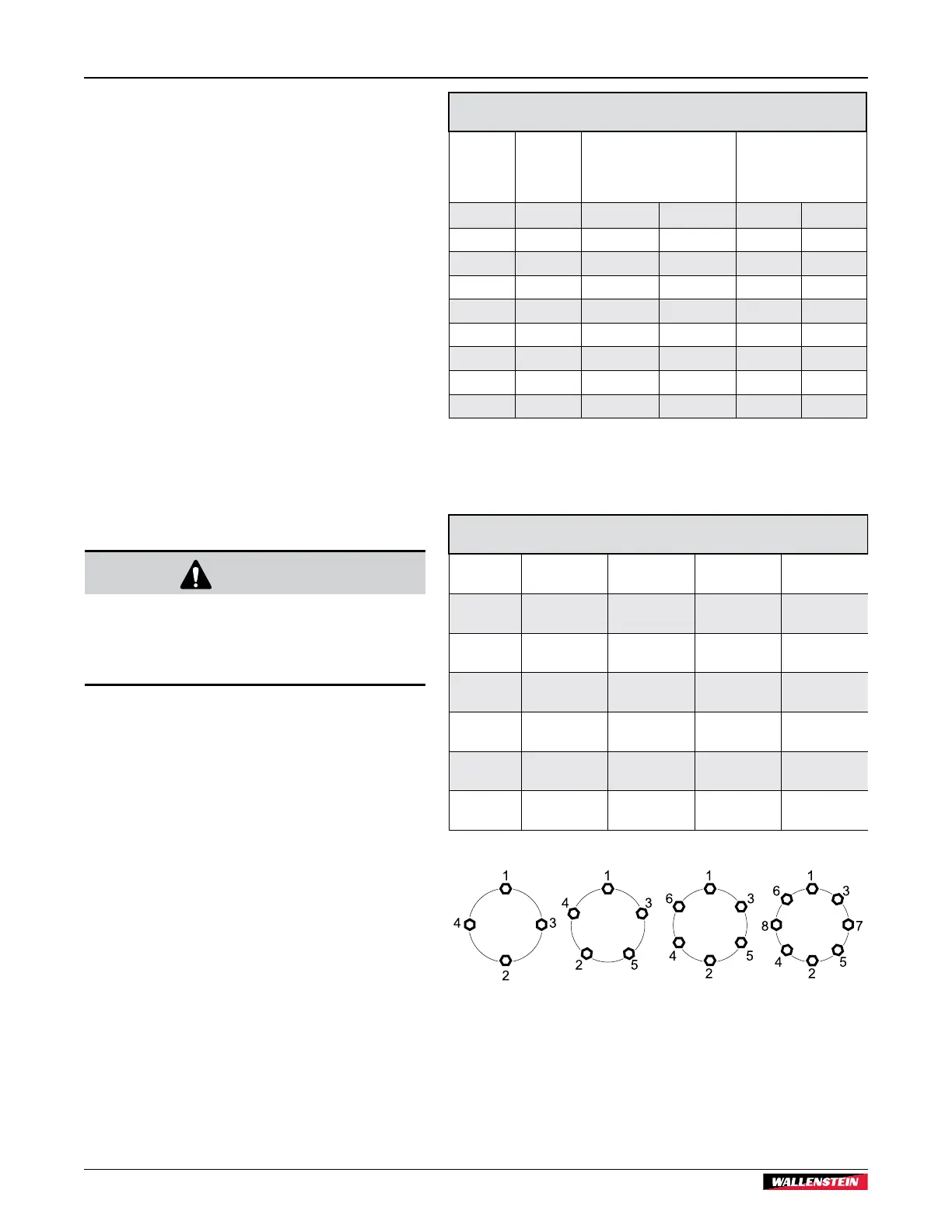

• Tighten lug nuts following the Wheel Lug Torque

Pattern. Tighten each set of lug nuts in stages, as

shown.

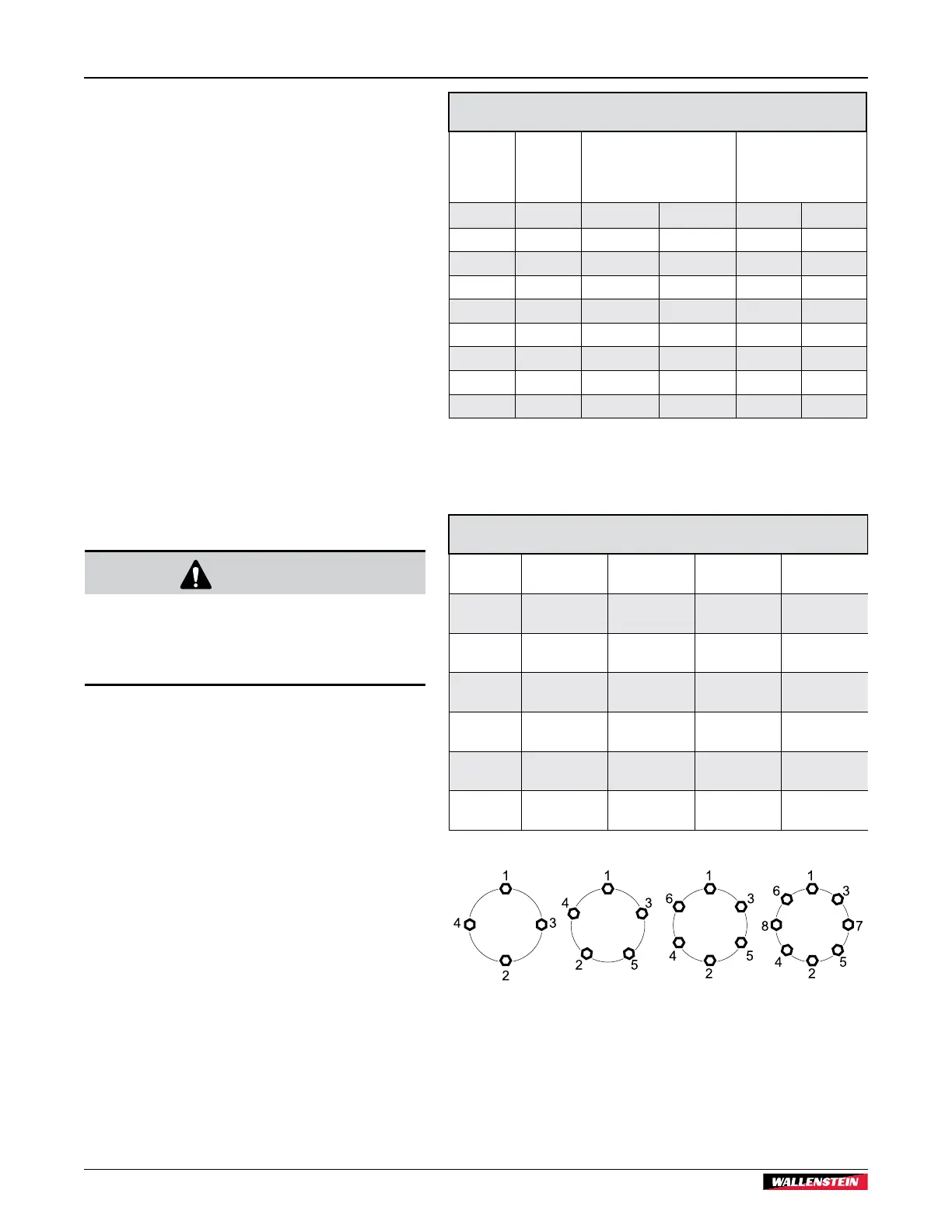

Wheel Lug Nut Torque

Wheel

Size

Units 1st Stage 2nd Stage 3rd Stage

8"

lbf•ft

N•m

12–20

16–26

30–35

39–45.5

45–55

58.5–71.5

12"

lbf•ft

N•m

20–25

26–32.5

35–40

45.5–52

50–60

65–78

13"

lbf•ft

N•m

20–25

26–32.5

35–40

45.5–52

50–60

65–78

14"

lbf•ft

N•m

20–25

26–32.5

50–60

65–78

90–120

117–156

15"

lbf•ft

N•m

20–25

26–32.5

50–60

65–78

90–120

117–156

16"

lbf•ft

N•m

20–25

26–32.5

50–60

65–78

90–120

117–156

4-Bolt

Wheel Lug Torque Pattern

5-Bolt 6-Bolt 8-Bolt

11.3 Hydraulic Fitting Torque

Tightening Flare Type Tube Fittings

1. Check flare and flare seat for defects that might

cause leakage.

2. Align tube with fitting before tightening.

3. Hand-tighten swivel nut until snug.

4. To prevent twisting the tube, use two wrenches.

Place one wrench on the connector body and tighten

the swivel nut with the second. Torque to values

shown.

If a torque wrench is not available, use the FFFT (Flats

From Finger Tight) method.

Hydraulic Fitting Torque

Tube

Size

OD

Hex

Size

Across

Flats

Torque value

Flats From

Finger Tight

Inches Inches

lbf•ft

N•m Flats Turns

3/16 7/16 6 8 2 1/6

1/4 9/16 11–12 15–17 2 1/6

5/16 5/8 14–16 19–22 2 1/6

3/8 11/16 20–22 27–30 1-1/4 1/6

1/2 7/8 44–48 59–65 1 1/6

5/8 1 50–58 68–79 1 1/6

3/4 1-1/4 79–88 107–119 1 1/8

1 1-5/8 117–125 158–170 1 1/8

Values shown are for non-lubricated connections.

Specifications

WP845 / WP875

Trailer Firewood Processor

66

Loading...

Loading...