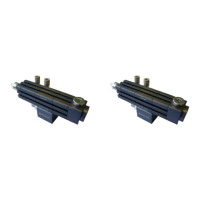

Assembly Instructions – Dosing Valves WDV-0x

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

8 Maintenance and Repair

8.1 General Information

CAUTION

Before starting any maintenance or repair work, ensure that all air-operated tools are

depressurized and disconnected from the air supply.

Before opening the dosing valve it must be disconnected from the air and fluid supply.

Otherwise, ejected components can cause injuries.

IMPORTANT

This chapter does not explain how to repair damage of the device. Repair work shall be

executed exclusively by skilled and trained experts, or by staff of the manufacturer`s

customer service.

8.2 Routine Tasks

The maintenance intervals stated below are valid for single-shift operation of the equipment. In case of

multiple-shift or very intensive operation, maintenance intervals must be shortened accordingly. Also take

into account other influences on maintenance need, such as dirty environment.

Check dosing valve for

leak-tightness and

damage

Check all screw

connections and

connections of

mountings for tightness

Check electrical

conducts for damage

CAUTION

After maintenance tasks are completed, check all functions and safety devices.

IMPORTANT

Only use soft brushes for outside cleaning of the nozzle tips. Never use metal tools

with sharp edges.

IMPORTANT

Only use original spare parts from the manufacturer!

Wrong or defective spare parts from other manufacturers can damage the device. If

other than original spare parts of the manufacturer will be used, all obligations from the

manufacturer or his sales partners, such as guarantees, service contracts etc will be

forfeited without further notice.

Loading...

Loading...