37

Inlet valve for W185

up to S/N 9508/011934

The water inlets have brass bodies with larger

cross section of the outlet in order to achieve a

shorter filling time for the machine.

Construction

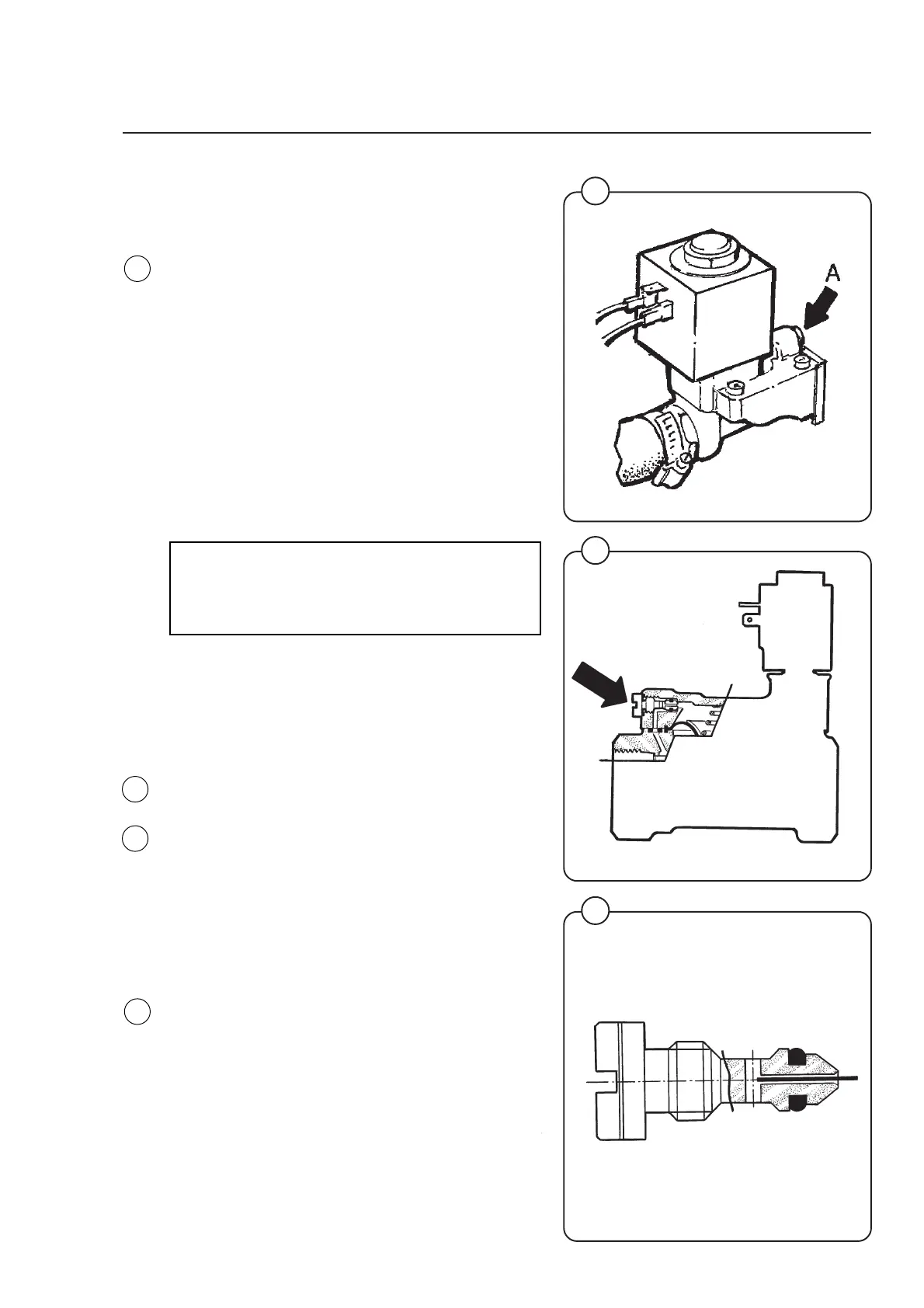

The valve housing is made of pressed brass. The

spring-loaded plunger is made of stain-less steel

and located at its lower end is a rubber gasket for

the pilot valve.

Operation

The valve is automatically operated by means of

a rubber diaphragm and a pilot valve in exactly

the same way as the supply injector valve.

NOTE: To strip, clean, re-assemble and

troubleshoot the inlet valve, follow the

instructions outlined for the supply

injector valve.

Clean out

At water temperatures of more than 60°C/140°F,

the lime deposits are heavily increased. This can

cause function problems due to blocking up the

equalizing orifice of the valve.

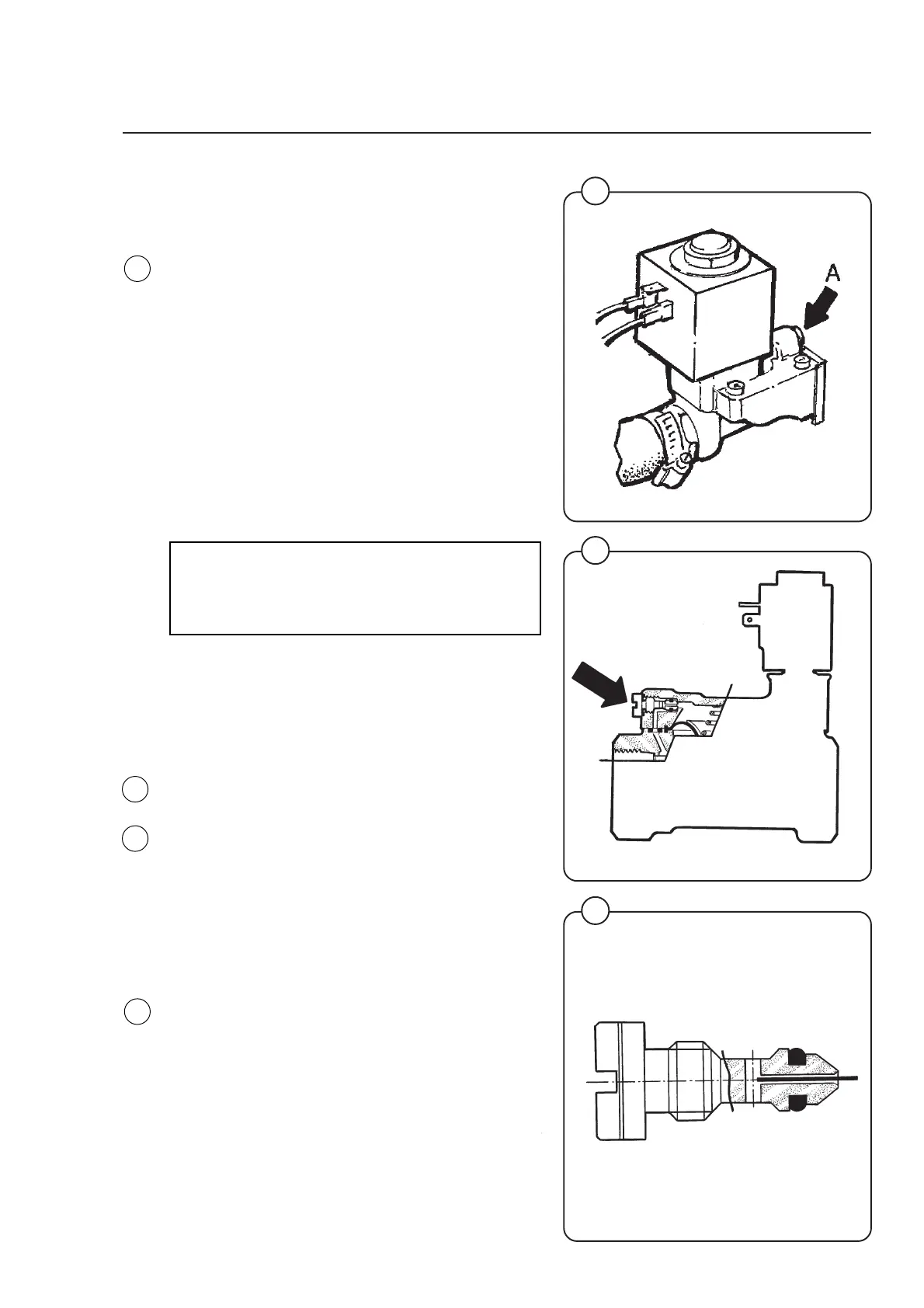

The fault can be eliminated by cleaning the

equalizing orifice (marked A).

If there are much deposits the orifice can be

changed from 0.5 mm to 0.8 mm. The screwhead

of the orifice is marked with 1 ring for the size of

0.5 mm and 2 rings for the size of 0.8 mm.

Clean the orifice as follows:

1. Shut off the main supply.

2. Unscrew the orifice.

3. Clean the hole in the orifice carefully with a

pin or similar not thicker than 0.5 resp.

0.8 mm.

4. Mount the orifice, be careful with sealing and

tighten.

5. Open the main supply.

Fig.

50

50

0311

Mechanical and electrical design

Fig.

51

52

0369

51

0368

Fig.

52

Fig.

50

Loading...

Loading...