2

1

⁄2" – 3"

(65-80mm) 009

*

1

⁄4" – 2"

(80-50mm)

009

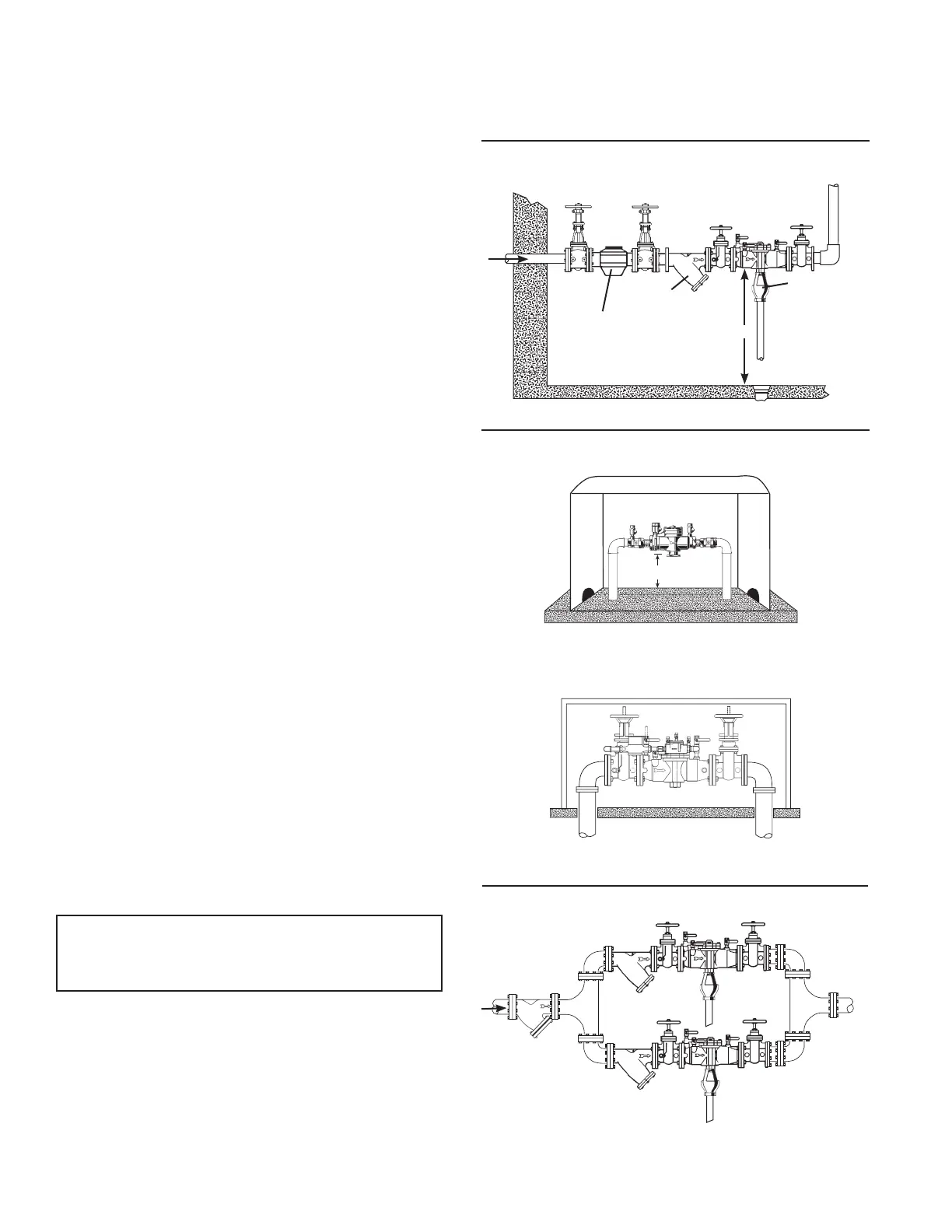

Figure 1

Figure 2

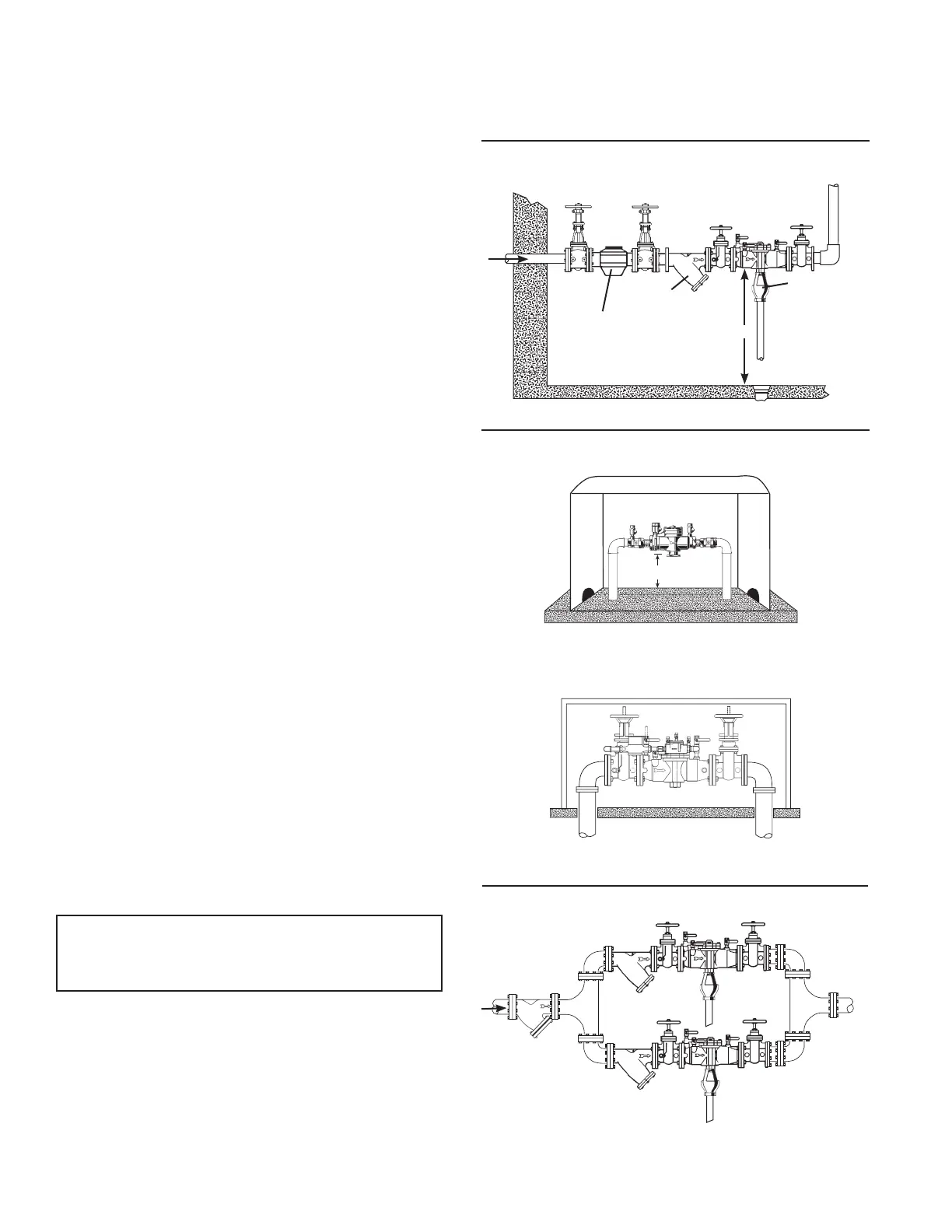

Figure 3

Air Gap

Main

Strainer

Meter

2

1

⁄2" – 3" (65-80mm) 009

12"

Fiberglass WattsBox

12"

Now available, WattsBox Insulated Enclosures,

for more information, send for literature ES-WB.

Now available, WattsBox Insulated Enclosures,

for more information, send for literature ES-WB.

WattsBox

2

1

⁄2" – 3"

(65-80mm) 009

Installation Instructions

Series 009 and LF009

2

Indoors – Figure 1

For indoor installations, it is important that the assembly be eas-

ily accessible to facilitate testing and servicing. If it is lo cat ed in a

line close to a wall, be sure the test cocks are easily accessible.

A drain line and air gap (see literature ES-AG/EL/TC) should

be piped from the relief valve connection as shown, where

evidence of discharge will be clearly visible and so that water

dam age will not occur. Therefore, never install in concealed

locations.

Outside – Figure 2

In an area where freezing conditions do not occur, Series 009 and

LF009 can be installed outside. The most sat is fac to ry in stal la tion

is above ground and should be in stalled in this manner when ev er

possible.

In an area where freezing conditions can occur, Series 009

and LF009 should be installed above ground in an insulated

enclosure.

Series 009 and LF009 must be installed in an ac ces si ble loca-

tion to facilitate testing and ser vic ing. A discharge line should be

piped from the air gap at the relief valve con nec tion making sure

that there is adequate drainage. Never pipe the discharge line

directly into a drainage ditch, sewer or sump. Series 009 and

LF009 should never be in stalled where any part of the unit could

become submerged in standing water.

It is generally recommended that back flow preventers never be

placed in pits unless absolutely necessary and then only when

approved by local codes. In such cases, a modified pit installa-

tion is preferred.

Parallel – Figure 3

Two or more smaller size assemblies can be piped in parallel (when

approved) to serve a large supply pipe main. This type of installa-

tion is employed where in creased capacity is needed beyond that

provided by a single valve and permits testing or servicing of an

individual valve without shutting down the complete line.

The number of assemblies used in par al lel should be deter-

mined by the en gi neer’s judgement based on the operating

con di tions of a specific installation.

For parallel valve installations, the total capacity of the assem-

blies should equal or exceed that required by the system.

Annual inspection of all water system safety and control

valves is required and necessary. Regular inspection,

testing and cleaning assures maximum life and proper

product function.

Loading...

Loading...