CLP–110–02–F–D–P

CLP–130–02–L–D

CLP–116–02–L–D

CLP–116–02–F–DH

High reliability

Tiger-Claw contacts

Low Profile

(2,21mm) .087"

(1,27mm x 1,27mm)

.050" x .050"

micro pitch

Surface

Mount

Suitable for

pass-through

applications

SAMTEC USA • Tel: 1-800-SAMTEC-9 or 812-944-6733 • Fax: 812-948-5047 SAMTEC UK • Tel: 01236 739292 • Fax: 01236 727113 SAMTEC ASIA PACIFIC • Tel: 65-745-5955 • Fax: 65-841-1502

SAMTEC GERMANY • Tel: +49 (0) 89 / 89460-0 • Fax: +49 (0) 89 / 89460-299 SAMTEC FRANCE • Tel: 01 60 95 06 60 • Fax: 01 60 95 06 61 SAMTEC ITALY • Tel: 39 039 6890337 • Fax: 39 039 6890315

SAMTEC JAPAN • Tel: 81-424-42-8318 • Fax: 81-424-42-8319 SAMTEC CHINA • Tel: 86-21-5385-4089 • Fax: 86-21-5385-4047 SAMTEC TAIWAN • Tel: (02) 2395-1677 • Fax: (02) 2395-1689

Due to technical progress, all designs, specifications and components are subject to change without notice.

FACTSHEET F-200

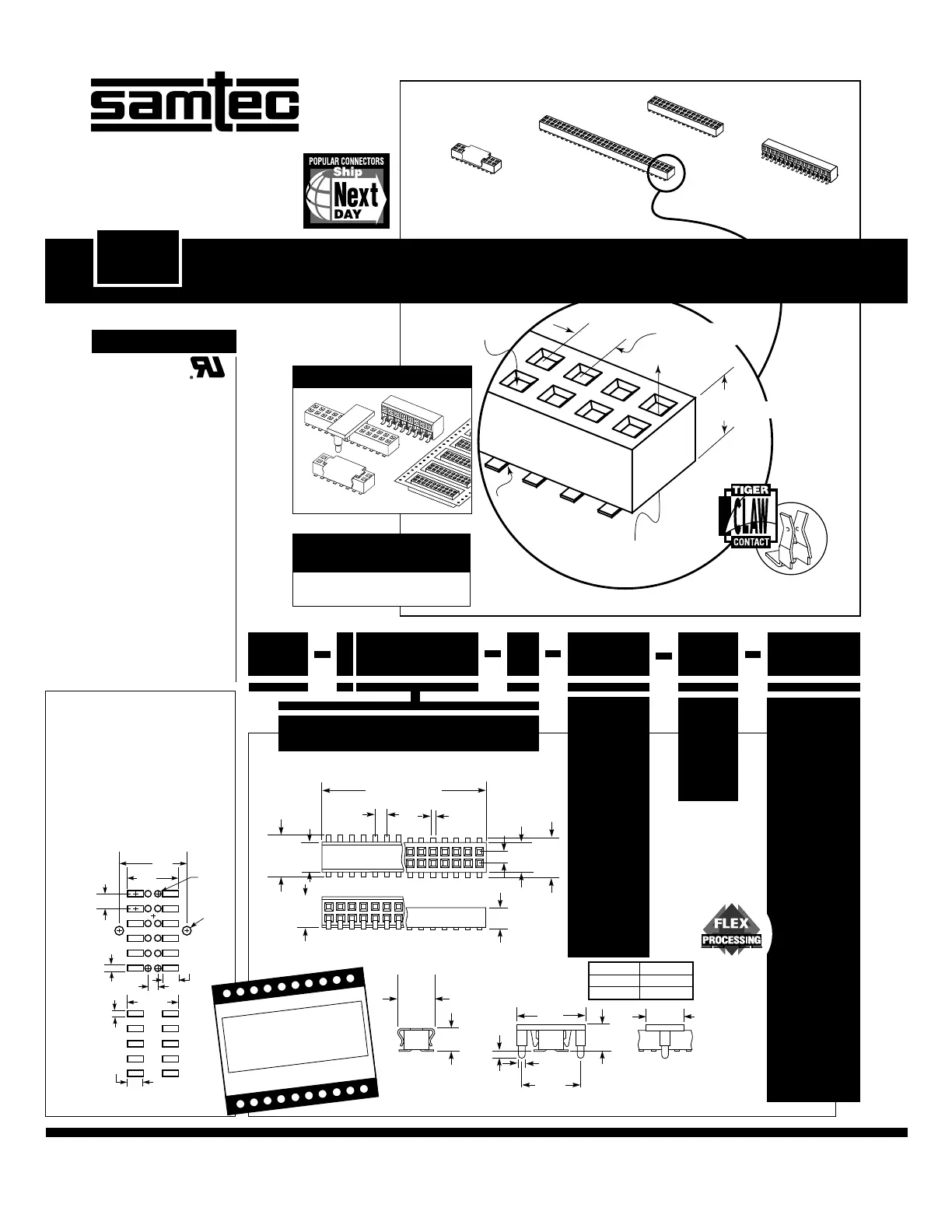

Processing:

Max Processing Temp:

230°C for 60 seconds

SMT Lead Coplanarity:

(0,10mm) .004" max (02-35)

(0,15mm) .006" max (36-50)

Suggested Paste

Thickness:

For most applications add

(0,05mm) .002" to max SMT

lead coplanarity

Suggested PCB Layouts:

Your specific layout may vary

Note: Some sizes, styles and

options are non-standard,

non-returnable.

LOW PROFILE SOCKETS

1

OTHER

OPTION

PLATING

OPTION

02 thru 50

NO. PINS

PER ROW

CLP

02

–BE

= Bottom Entry

(Required

for bottom entry

applications)

–K

(Best Cost Option)

= (4,00mm) .157"

DIA Polyamide film

Pick & Place Pad

(5 positions min.)

–P

= Pick & Place Pad

(5 positions min.

–D only)

(Not always

necessary for

auto placement.

See Flex

Processing.)

–PA

= Pick &

Place Pad with

Alignment Pin

(–D only)

–TR

= Tape & Reel

Mates with:

FTSH, FTS, FW, DIS5

CLP

SERIES

OPTIONS

–TR OPTION

ROW

OPTION

–D

= Double

Row

–DH

= Double

Horizontal

–P OPTION

–DH OPTION

–PA OPTION

Alignment pins available.

Call Samtec.

APPLICATION

SPECIFIC OPTION

–G

(Best Cost

Option)

= 10

µ" (0,25µm)

Gold

(–D only)

–F

= Pre-plated

Gold flash

on contact,

75

µ" (1,91µm)

Tin on tail

–L

= Pre-plated

(0,25

µm) 10µ"

Gold on contact,

75

µ" (1,91µm)

Tin on tail

No. of Positions

x (1,27).050

(1,27)

.050

(1,27)

.050

(0,46)

.018

(3,05)

.120

(3,05)

.120

(4,57)

.180

(4,32)

.170

(2,44)

.096

(6,35)

.250

x

(3.18)

.125

99

100

01

02

(2,26)

.089

(3,43)

.135

(0,89)

.035 DIA

(7,00)

.275

(3,00)

.118

(1,40)

.055

(8,25)

.325

A

A

(3,56) .140

(7,11) .280

PIN/ROW

04-15

16-50

Board fixturing may be required

to assure proper alignment for

pass-through applications.

–DH

–D

(5,21)

.205

(0,74)

.029

DIA

(Pass-Thru)

(0,74)

.029

(6,98)

.275

(1,27)

.050

TYP

(1,47)

.058

(1,27)

.050

-PA

Option

(0,93)

.037

DIA(2)

(5,33)

.210

(0,71)

.028

(1,35)

.053

TAPE & REEL AVAILABILITY

Call Samtec for specifications

and ordering information.

No tooling charges.

125 piece minimum order.

Order any quantity above minimum.

In-house design, manufacture.

Quick turn-around.

SPECIFICATIONS

Materials:

Insulator Material:

Black Liquid Crystal Polymer

Contact Material:

Phosphor Bronze

Current Rating:

1.75A @ 80°C ambient

Operating Temp Range:

-65°C to +125°C

Plating: Sn or Au over

50µ" (1,27µm) Ni

Contact Resistance:

10 mΩ max

Insertion Depth:

Top Entry = (1,40mm) .055"

minimum, Bottom Entry =

(2,21mm) .087" minimum

plus board thickness

DH Entry = (2,31mm) .091"

to (2,67mm) .105"

Insertion Force:

3.8oz (1,05N) average

Normal Force:

60 grams (0,59N) average

Withdrawal Force:

2oz (0,56N) average

Max Cycles:

100 with 10µ" (0,25µm) Au

–DH

–PA OPTION

–D

–P OPTION

Alignment pins are located

about centerline of the part. If

odd pins/row then on middle

position. If even then between

middle two positions.

Surface

SMT

Mount

C

O

S

T

S

A

V

I

N

G

S

O

L

U

T

I

O

N

S

Loading...

Loading...