Digital

Noise

Amplitude

Symmetry

\/

1. Set function selector

to

_JU

[_,

NOISE FREQ HZ

selector

to

160

kHz, and depress

SEQUENCE

LENGTH

-

215

-

1

push button.

2.

Connect oscilloscope, with peak mV

plug-in, to

location DN on

digital

board.

3.

Adjust R36, using comparator,

to provide

a

positive peak

of +1.25 V ±10 mV.

4. Adjust

R39, using comparator, to provide

a

negative

peak of

—1.25

V

±10

mV.

Analog Noise

Amplitude Symmetry

1. Connect BNC

cable to NOISE SYNC connector

(rear

panel) and sync

connector on oscilloscope.

2.

Depress

SEQUENCE LENGTH

-

2

1S

-

1

push

button.

3. Connect

oscilloscope

to

location AN on digital

board.

4. Adjust

R22 (gain) and R23 (balance)

to provide

a 2.5 V

p-p

signal centered

about ground.

S/N

Frequency

Compensation

\/

1. Set function

selector to

Hj

.

2.

Depress MODE

—

S/N push button.

3. Set frequency dial

to 1.0

and

FREQ HZ

selector

to X100K (100 kHz).

4. Set S/N

—

N/S

(dB)

selector to

+50 position

and turn vernier

to

+9

position to provide

ap-

proximately

+59 dB.

5. Turn

OUTPUT

VERNIER

(dB) full

cw.

6.

Connect

oscilloscope

to

50^2

OUT connector

with

5012 terminator

(

n

u

function).

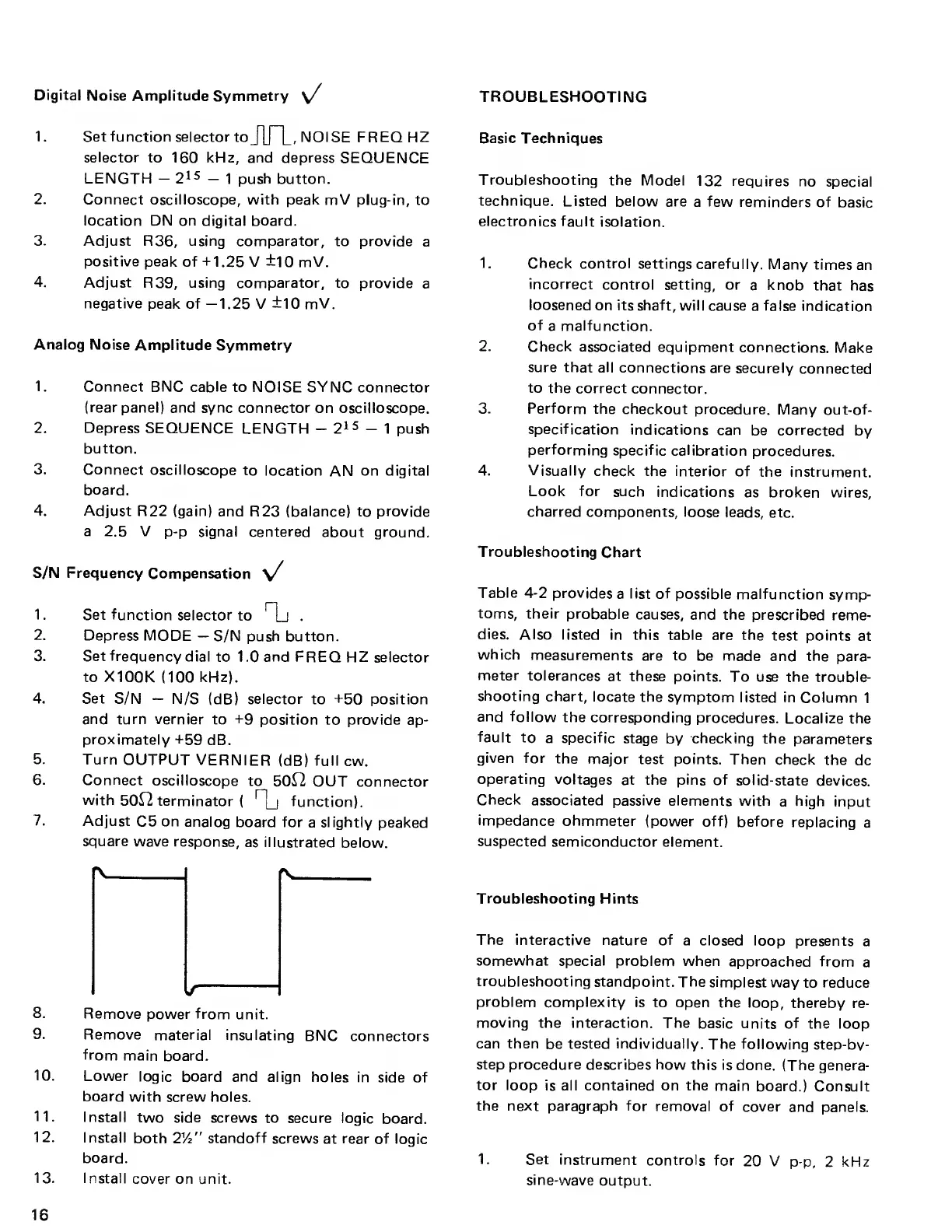

7.

Adjust

C5

on analog

board for

a

slightly

peaked

square

wave response,

as illustrated

below.

8.

Remove

power from

unit.

9.

Remove

material insulating

BNC

connectors

from

main

board.

10.

Lower

logic board and

align

holes in

side of

board

with screw holes.

11.

Install

two side

screws to secure

logic

board.

12.

Install

both

2y2

”

standoff

screws

at rear of logic

board.

13. I nstall

cover on unit.

TROUBLESHOOTING

Basic Techniques

Troubleshooting

the

Model

132 requires

no

special

technique.

Listed

below are

a

few

reminders

of

basic

electronics fault

isolation.

1. Check control

settings carefully.

Many times

an

incorrect

control

setting, or

a

knob

that

has

loosened

on its shaft, will

cause

a false

indication

of

a

malfunction.

2.

Check associated

equipment

connections.

Make

sure that all

connections are

securely

connected

to the

correct

connector.

3. Perform

the

checkout

procedure. Many

out-of-

specification

indications

can

be corrected

by

performing

specific calibration

procedures.

4.

Visually check

the interior

of the

instrument.

Look for

such

indications

as broken

wires,

charred

components,

loose leads, etc.

Troubleshooting

Chart

Table

4-2

provides

a

list of

possible

malfunction

symp-

toms, their

probable

causes, and

the prescribed

reme-

dies.

Also listed in this

table are the

test

points

at

which

measurements

are to

be made and

the para-

meter

tolerances

at these

points.

To use the

trouble-

shooting

chart, locate

the

symptom

listed

in

Column

1

and follow

the corresponding

procedures.

Localize

the

fault

to

a specific

stage

by

checking

the

parameters

given for

the

major test

points. Then

check the

dc

operating

voltages

at the pins of

solid-state

devices.

Check

associated passive elements

with

a

high

input

impedance

ohmmeter

(power off)

before

replacing

a

suspected

semiconductor

element.

Troubleshooting Hints

The

interactive nature of

a closed loop

presents

a

somewhat special

problem when

approached from

a

troubleshooting

standpoint.

The simplest

way

to

reduce

problem complexity

is to open the

loop, thereby

re-

moving

the interaction. The

basic units of

the loop

can then

be

tested individually.

The following

step-bv-

step procedure describes how

this is done.

(The genera-

tor loop

is all contained on the

main

board.) Consult

the

next paragraph for

removal of

cover

and panels.

1. Set

instrument

controls

for

20 V

p-p,

2

kHz

sine-wave

output.

16

Loading...

Loading...